- inCAD Library Home

- > No.000014 Surface locating mechanism using two flat plates

No.000014 Surface locating mechanism using two flat plates

12

12

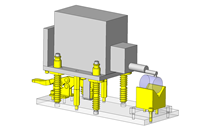

High accuracy surface locating mechanism using two plates for reference

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

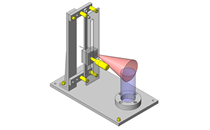

- A simplified surface plate for objects with protrusions on the bottom that cannot be placed on coplanar surface plates.

Target workpiece

- Molded plastic product

Dims.: W280 x D40 x H25

Weight: 0.18kg

Design Specifications

Operating Conditions or Design Requirements

- External dims.: W300 x D100 x H52.2

Selection Criteria for Main Components

- Aluminum extrusion frame

- Two surface machined product selected for high accuracy.

Design Evaluation

Other Design Consideration

- Workpiece dimensions of W280 x D40 with protrusions on the bottom prevent the use of a conventional surface plate.

- Separate pieces are machined together to obtain the needed accuracy. This saves costs as well as overall weight.

- While the surfaces need to be stainless, the supporting structure can be made of light weight aluminum.

- To avoid applying loads on the screws during simultaneous machining, the stainless steel plates and aluminum plates are pinned and screwed together.

- Accurate flatness is obtained by setting up and machining the two plates in one center.

- The caps must be machined to not protrude from the extrusion cross section.

Explore Similar Application Examples

Page

-

/

-