- inCAD Library Home

- > No.000078 Soldering fixture

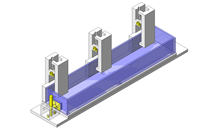

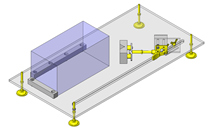

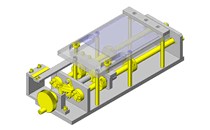

No.000078 Soldering fixture

10

10

Workpiece holding using magnets.

Related Category

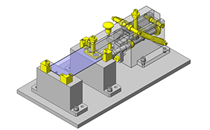

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- A fixture for soldering PC board.

Points for use

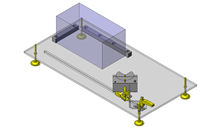

- Operating procedure

- The PC board is held down by the fixtures cover.

- User can perform soldering work on the first side of the PC board.

- After soldering the first side, lift up the cover, then remove and refit the PC board to its opposite side.

- Fold down the fixture cover again and begin soldering work on the 2nd side of the PC board.

Target workpiece

- PC board

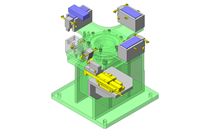

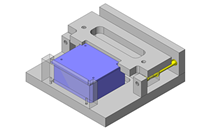

- Dims.: W70 x D45 x t1 (Also compatible with PCB W40 x D80 x t1)

Design Specifications

Operating Conditions or Design Requirements

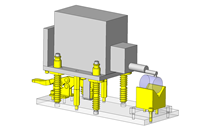

- External dims.: W120 x D120 x H30

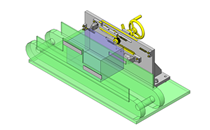

- Magnet; 7.84N

Required accuracy ・ Load

- Cover retaining force: 5.9N

Selection Criteria for Main Components

- Magnet

- Magnetic hold down force should be sufficient to keep the PCB in place during soldering, and yet minimal enough for easy lifting of the cover when soldering is complete.

- As an example, select magnets with attraction force of approximately 5.9N.

Design Evaluation

Verification of main components

- Consider adding handle or hex posts for lifting of cover and overall handling of the fixture.

- When reversing, load applicable on the magnets: Cover + Hex posts + PCB = 45g + 10g + 5g = 60g = 0.59N

- Distance between the magnets and magnetic material: 2mm (Magnetic material: EN 1.7220 Equiv., screw head)

- Assumed decay: 0.1

- Attraction to prevent cover opening: 0.59 / 0.1 = 5.9N

- Magnetic attraction can vary based on distance, temperature, material and size of magnetic body. Selection is to be made upon actual measurements.

Other Design Consideration

- Since soldering is applied on reversed sides, hex posts are provided as feet on the cover side. The posts are also used as handles for cover open/close.

- Locating pins are used to locate the cover.

- Add notches as needed to avoid wire harness, etc.

- The hex socket screw heads are used as attracted member since the main body and the cover are made of non-magnetically permeable material.

Explore Similar Application Examples

Page

-

/

-