- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 3:00 21/4/2024 to 0:00 (CET) 22/4/2024. We apologize for the inconvenience.

Jig Pins / Standard(h7) / Square Head / No Shoulder / Threaded

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Type | Material | Hardness | |

| Threaded | Set Screw | ||

| LNNQN | LNTQN | EN 1.7220 Equiv. | Treated Hardness 35~40HRC |

| TLNNQN | TLNTQN | EN 1.7242 Equiv. | Carburized Treated Hardness: 55HRC~ (Depth: 0.7 ~ 0.8) / Anti-carburizing on Threads |

Specifications

| Part Number | - | P | - | W | - | B | - | L | - | A | - | E | ||||

| Type | Tip Shape | D | ||||||||||||||

| LANQN LNNQN | A B | 6 8 | P7.0 P12.0 | - - | W5.0 W10.0 | - - | B15 B18 | - - | L8 L8 | - - | A30 A60 | - | E8 | |||

| Part Number | P 0.1mm Increment | W 0.1mm Increment | B 1mm Increment | L Selection | A Selection | E (Shape A) 1mm Increment | L1 | ℓ | ℓ1 | d | R | Applicable Set Screw | Unit Price | |||||||||

| Type | Tip Shape | Dh7 | LNNQN LNTQN | TLNNQN TLNTQN | ||||||||||||||||||

| Hardened (Threaded) LNNQN (Set Screw) LNTQN | Carburized (Threaded) TLNNQN (Set Screw) TLNTQN | A (Tapered) B (Taper R) | 6 | 0 -0.012 | 9.0~12.0 | 5.0~30.0 (W≤P) | 5~30 (B≤Wx3) | 5 | 8 | 10 | 30 60 90 120 | 1~10 | 8 | 6 | 8 | 4 | 3 | M5 | ||||

| 8 | 0 -0.015 | 11.0~16.0 | 5 | 8 | 10 | 12 | 15 | 10 | 8 | 5 | 4 | M5 | ||||||||||

| 10 | 13.0~20.0 | 8 | 10 | 12 | 15 | 10 | 12 | 8 | 7 | 4 | M6 | |||||||||||

| 10T | 13.0~20.0 | 8 | 10 | 12 | 15 | 5 | 15 | 8 | 7 | 4 | M6 | |||||||||||

| 12 | 0 -0.018 | 15.0~25.0 | 10 | 12 | 15 | 18 | 12 | 15 | 10 | 9 | 6 | M8 | ||||||||||

| 16 | 19.0~32.0 | 12 | 15 | 18 | 20 | 18 | 10 | 13 | 8 | M8 | ||||||||||||

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| LNNQNA6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10]-A[30,60,90,120]-E[1-10/1] |

| LNNQNA8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| LNNQNA10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| LNNQNA10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| LNNQNA12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-L[10,12,15,18]-A[30,60,90,120]-E[1-10/1] |

| LNNQNA16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-L[12,15,18,20]-A[30,60,90,120]-E[1-10/1] |

| LNNQNB6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10]-A[30,60,90,120] |

| LNNQNB8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10,12,15]-A[30,60,90,120] |

| LNNQNB10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120] |

| LNNQNB10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120] |

| LNNQNB12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-L[10,12,15,18]-A[30,60,90,120] |

| LNNQNB16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-L[12,15,18,20]-A[30,60,90,120] |

| LNTQNA6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNA8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNA10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNA10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNA12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNA16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| LNTQNB6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| LNTQNB8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| LNTQNB10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| LNTQNB10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| LNTQNB12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| LNTQNB16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNNQNA6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNA8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNA10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNA10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNA12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-L[10,12,15,18]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNA16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-L[12,15,18,20]-A[30,60,90,120]-E[1-10/1] |

| TLNNQNB6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10]-A[30,60,90,120] |

| TLNNQNB8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-L[5,8,10,12,15]-A[30,60,90,120] |

| TLNNQNB10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120] |

| TLNNQNB10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-L[8,10,12,15]-A[30,60,90,120] |

| TLNNQNB12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-L[10,12,15,18]-A[30,60,90,120] |

| TLNNQNB16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-L[12,15,18,20]-A[30,60,90,120] |

| TLNTQNA6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNA8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNA10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNA10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNA12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNA16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120]-E[1-10/1] |

| TLNTQNB6-P[9-12/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNTQNB8-P[11-16/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNTQNB10-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNTQNB10T-P[13-20/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNTQNB12-P[15-25/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| TLNTQNB16-P[19-32/0.1]-W[5-30/0.1]-B[5-30/1]-A[30,60,90,120] |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Inlet Side Tip Type | Mounting Side Shape | Material | Mounting Side Dia. D (Ø) | Heat Treatment | Insertion Guide Section Outer Dia. P (Ø) | Mounting Section Length L (mm) | Positioning Part Length B (mm) | Taper Length E (mm) | A (°) | Tip W (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | 9 ~ 12 | 5 ~ 10 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | 11 ~ 16 | 5 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | 15 ~ 25 | 10 ~ 18 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | 19 ~ 32 | 12 ~ 20 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | 9 ~ 12 | 5 ~ 10 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | 11 ~ 16 | 5 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | 15 ~ 25 | 10 ~ 18 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | 19 ~ 32 | 12 ~ 20 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | 9 ~ 12 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | 11 ~ 16 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | 13 ~ 20 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | 13 ~ 20 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | 15 ~ 25 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | 19 ~ 32 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 6 | Directly Quenched | 9 ~ 12 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 8 | Directly Quenched | 11 ~ 16 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10 | Directly Quenched | 13 ~ 20 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 10T | Directly Quenched | 13 ~ 20 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 12 | Directly Quenched | 15 ~ 25 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7220 Equiv. | 16 | Directly Quenched | 19 ~ 32 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 6 | - | 9 ~ 12 | 5 ~ 10 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 8 | - | 11 ~ 16 | 5 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 10 | - | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 10T | - | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 12 | - | 15 ~ 25 | 10 ~ 18 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Threads | [Steel] EN 1.7242 Equiv. | 16 | - | 19 ~ 32 | 12 ~ 20 | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 6 | - | 9 ~ 12 | 5 ~ 10 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 8 | - | 11 ~ 16 | 5 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 10 | - | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 10T | - | 13 ~ 20 | 8 ~ 15 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 12 | - | 15 ~ 25 | 10 ~ 18 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Threads | [Steel] EN 1.7242 Equiv. | 16 | - | 19 ~ 32 | 12 ~ 20 | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 6 | - | 9 ~ 12 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 8 | - | 11 ~ 16 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 10 | - | 13 ~ 20 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 10T | - | 13 ~ 20 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 12 | - | 15 ~ 25 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tapered (Shape A) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 16 | - | 19 ~ 32 | - | 5 ~ 30 | 1 ~ 10 | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 6 | - | 9 ~ 12 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 8 | - | 11 ~ 16 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 10 | - | 13 ~ 20 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 10T | - | 13 ~ 20 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 12 | - | 15 ~ 25 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 | ||

- | 1 | 9 Days | 10 | Tip R (Shape B) | Circumference Groove (Set Screw) | [Steel] EN 1.7242 Equiv. | 16 | - | 19 ~ 32 | - | 5 ~ 30 | - | 30 ~ 120 | 5 ~ 30 |

Loading...

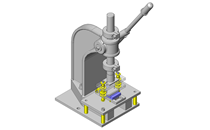

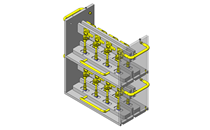

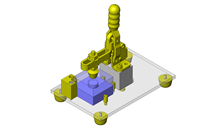

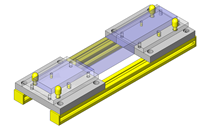

Example of Use

Basic information

| Basic Shape | Pins for Fixtures - No Shoulder | Inlet Side Tip Shape | Diamond-Shaped | Concentricity | Others Ø0.1 |

|---|---|---|---|---|---|

| Inlet Side Tolerance | Standard Grade 0/-0.05 |

Configure

Basic Attributes

-

Inlet Side Tip Type

-

Tapered (Shape A)

Tapered (Shape A) -

Tip R (Shape B)

Tip R (Shape B)

-

-

Mounting Side Shape

-

Threads

Threads -

Circumference Groove (Set Screw)

Circumference Groove (Set Screw)

-

-

Material

- Steel

- Steel

-

Mounting Side Dia. D(Ø)

-

Heat Treatment

- Directly Quenched

-

Insertion Guide Section Outer Dia. P(Ø)

-

Mounting Section Length L(mm)

-

Positioning Part Length B(mm)

-

Taper Length E(mm)

-

A(°)

-

Tip W(mm)

-

Type

- LNNQN□

- LNTQN□

- TLNNQN□

- TLNTQN□

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 9 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)