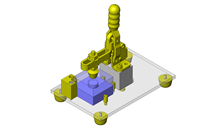

Locating pins, Centring pins / head shape selectable / chamfered flat head / fastening variant selectable

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Material No. | Material | Surface Treatment | Hardness | Type | Shape Code | ||

| Press Fit | Tapped | Threaded | |||||

| EN 1.2510 Equiv. | - | Treated Hardness: 60 ~ 63HRC | KF | KFT | KFN | A (Round) D (Diamond) | |

| EN 1.2510 Equiv. | Hard Chrome Plating | Treated Hardness: 50 ~ 55HRC Plating Hardness: 750HV ~ | GKF | GKFT | GKFN | ||

| EN 1.2510 Equiv. | - | - | BKF | BKFT | BKFN (Round only) | ||

| EN 1.4301 Equiv. | - | - | SKF | SKFT | SKFN | ||

| EN 1.4301 Equiv. | Hard Chrome Plating | Plating Hardness: 750HV ~ | HKF | HKFT | HKFN | ||

| EN 1.4037 Equiv. | - | Treated Hardness: 50 ~ 55HRC | CKF | CKFT | - | ||

Specifications

| Part Number | - | P | - | L | - | B | - | E | - | A | ||||||||

| Type | Shape | D Tol. | P Tolerance | D | ||||||||||||||

| KF GKFT SKFN | A A D | M G G | S S B | 6 10T 12 | - - - | P10.00 P13.00 P15.00 | - - - | L6 L6 L12 | - - - | B3.0 B4.0 B5.0 | - - - | E5.0 E10.0 E7.0 | - - - | A30 A15 A45 | ||||

| D or P | Standard Grade | Precision Grade | |||||

| M | P | G | H | S | A | B | |

| m6 | p6 | g6 | h7 | - | - | - | |

| 1.00 ~ 3.00 | +0.008 +0.002 | +0.012 +0.006 | -0.002 -0.008 | 0 -0.010 | 0 -0.01 | +0.005 0 | 0 -0.005 |

| 3.01 ~ 6.00 | +0.012 +0.004 | +0.020 +0.012 | -0.004 -0.012 | 0 -0.012 | |||

| 6.01 ~ 10.00 | +0.015 +0.006 | +0.024 +0.015 | -0.005 -0.014 | 0 -0.015 | |||

| 10.01 ~ 18.00 | +0.018 +0.007 | +0.029 +0.018 | -0.006 -0.017 | 0 -0.018 | |||

| 18.01 ~ 30.00 | +0.021 +0.008 | +0.035 +0.022 | -0.007 -0.020 | 0 -0.021 | |||

Hard Chrome Plating products are not available for Precision Grade Tolerance.

EN 1.4037 Equiv. has an identification groove at any position on D part.

Polished, centering hole is sometimes not available for EN 1.4301 Equiv.

P-2EtanA≥0.73 (Tip dia. Ø0.73 or more)

Reference:tan15°≈0.267 tan30°≈0.577

tan45°=1 tan60°≈1.732

■Press Fit

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | E 0.1mm Increment | A Selection | C | (W) | ||||

| Type | Shape | D Tolerance | P Tolerance | D | |||||||

| KF GKF * BKF SKF HKF * CKF | A (Round) D (Diamond) | M P G H *A *B | S M P G H *A *B | 1 | 1.00~2.50 (1.50~2.00) | 2, 3 | 2.0~5.0 | 0.5~10.0 | 15 30 45 60 | 0.1 | 0.6 |

| 2 | 2.00~4.00 | 2~6 | 2.0~10.0 | 0.5 | 1.2 | ||||||

| 3 | 3.00~6.00 | 3~6 | 2.0~10.0 | 1.5 | |||||||

| 4 | 4.00~7.00 | 4~8 | 2.0~10.0 | 1 | 1.8 | ||||||

| 5 | 5.00~8.00 | 5~10 | 2.0~10.0 | 2.2 | |||||||

| 6 | 6.00~10.00 | 6~12 | 2.0~12.0 | 3 | |||||||

| 8 | 8.00~13.00 | 8~16 | 2.0~15.0 | 1.5 | 3.5 | ||||||

| 10 | 10.00~15.00 | 10~20 | 3.0~20.0 | 2 | 4 | ||||||

| 12 | 12.00~16.00 | 12~24 | 3.0~20.0 | 5 | |||||||

| 13 | 13.00~18.00 | 13~26 | 5.0~20.0 | 5.5 | |||||||

| 16 | 16.00~25.00 | 16~32 | 5.0~20.0 | 3 | 7 | ||||||

| 20 | 20.00~30.00 | 20~40 | 5.0~20.0 | 9 | |||||||

■Tapped

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | E 0.1mm Increment | A Selection | (W) | M (Coarse) | * Tightening Torque N • cm | ℓ | ||||

| Type | Shape | D Tolerance | P Tolerance | D | |||||||||

| KFT GKFT BKFT SKFT HKFT CKFT | A (Round) D (Diamond) | M P G H | S M P G H | 5 | 5.00~8.00 | 5(9)~10 | 2.0~10.0 | 0.5~10.0 | 15 30 45 60 | 2.2 | M2 | - | 3 |

| 6 | 6.00~10.00 | 6(9)~12 | 2.0~12.0 | 3 | M3 | 98 | 5 | ||||||

| 6T | M2.6 | - | 4 | ||||||||||

| 8 | 8.00~13.00 | 8(12)~16 | 2.0~15.0 | 3.5 | M5 | 461 | 8 | ||||||

| 8T | 6(12)~16 | M4 | 225 | 6 | |||||||||

| 10 | 10.00~15.00 | 10(12)~20 | 3.0~20.0 | 4 | M5 | 461 | 8 | ||||||

| 10T | 6(12)~16 | M4 | 225 | 6 | |||||||||

| 12 | 12.00~16.00 | 12~24 | 3.0~20.0 | 5 | M5 | 461 | 8 | ||||||

| 12T | 8(12)~18 | M4 | 225 | 6 | |||||||||

| 13 | 13.00~18.00 | 13(14)~26 | 5.0~20.0 | 5.5 | M8 | 1911 | 10 | ||||||

| 13T | 8(14)~20 | M6 | 784 | 9 | |||||||||

| 16 | 16.00~25.00 | 16~32 | 5.0~20.0 | 7 | M8 | 1911 | 12 | ||||||

| 16T | 10(14)~24 | M6 | 784 | 9 | |||||||||

| 20 | 20.00~30.00 | 20~40 | 5.0~20.0 | 9 | M8 | 1911 | 12 | ||||||

| 20T | 12(18)~30 | M6 | 784 | 9 | |||||||||

Note the strength of under-head part. >>P.1566 L dimension in ( ) is applicable to Diamond Shape. Please confirm pilot hole depth on >>P.1566. Holes may go through.

* The tightening torque (ref. value) for hardened products is strength class 8.8. (See technical data on >>P. 2297.) Not applicable when using locking materials or lock washers.

■Threaded

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | E 0.1mm Increment | A Selection | M (Coarse) | * Tightening Torque N • cm | (W) | ||||

| Type | Shape | D Tolerance | P Tolerance | D | ||||||||

| KFN GKFN* BKFN SKFN HKFN* | A (Round) D (Diamond) | M P G H *A *B | S M P G H *A *B | 3 | 3.50~6.00 | 2~6 | 2.0~10.0 | 0.5~10.0 | 15 30 45 60 | M 3 | 98 | 1.5 |

| 4 | 4.50~7.00 | 2~8 | 2.0~10.0 | M 4 | 225 | 1.8 | ||||||

| 5 | 5.50~8.00 | 3~10 | 2.0~10.0 | M 5 | 461 | 2.2 | ||||||

| 6 | 6.50~10.00 | 3~10 | 2.0~12.0 | M 6 | 784 | 3 | ||||||

| 8 | 9.00~13.00 | 5~10 | 2.0~15.0 | M 8 | 1911 | 3.5 | ||||||

| 10 | 11.00~15.00 | 5~15 | 3.0~20.0 | M10 | 3783 | 4 | ||||||

| 12 | 13.00~18.00 | 8~15 | 3.0~20.0 | M12 | 6605 | 5 | ||||||

| 16 | 17.00~25.00 | 8~20 | 5.0~20.0 | M16 | 16366 | 7 | ||||||

| 20 | 22.00~30.00 | 10~20 | 5.0~20.0 | M20 | 32928 | 9 | ||||||

* The tightening torque (ref. value) for hardened products is strength class 8.8. (See technical data on >>P. 2297.) Not applicable when using locking materials or lock washers.

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| BKFAAA1-P[1-2.5/0.01]-L[2-3/1]-B[2-5/0.1]-E[0.5-10/0.1]-A[15,30,45,60] |

| BKFAAA2-P[2-4/0.01]-L[2-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA3-P[3-6/0.01]-L[3-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA4-P[4-7/0.01]-L[4-8/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA5-P[5-8/0.01]-L[5-10/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA6-P[6-10/0.01]-L[6-12/1]-B[2-12/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA8-P[8-13/0.01]-L[8-16/1]-B[2-15/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA10-P[10-15/0.01]-L[10-20/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA12-P[12-16/0.01]-L[12-24/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA13-P[13-18/0.01]-L[13-26/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA16-P[16-25/0.01]-L[16-32/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAA20-P[20-30/0.01]-L[20-40/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB1-P[1-2.5/0.01]-L[2-3/1]-B[2-5/0.1]-E[0.5-10/0.1]-A[15,30,45,60] |

| BKFAAB2-P[2-4/0.01]-L[2-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB3-P[3-6/0.01]-L[3-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB4-P[4-7/0.01]-L[4-8/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB5-P[5-8/0.01]-L[5-10/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB6-P[6-10/0.01]-L[6-12/1]-B[2-12/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB8-P[8-13/0.01]-L[8-16/1]-B[2-15/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB10-P[10-15/0.01]-L[10-20/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB12-P[12-16/0.01]-L[12-24/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB13-P[13-18/0.01]-L[13-26/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB16-P[16-25/0.01]-L[16-32/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAB20-P[20-30/0.01]-L[20-40/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG1-P[1-2.5/0.01]-L[2-3/1]-B[2-5/0.1]-E[0.5-10/0.1]-A[15,30,45,60] |

| BKFAAG2-P[2-4/0.01]-L[2-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG3-P[3-6/0.01]-L[3-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG4-P[4-7/0.01]-L[4-8/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG5-P[5-8/0.01]-L[5-10/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG6-P[6-10/0.01]-L[6-12/1]-B[2-12/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG8-P[8-13/0.01]-L[8-16/1]-B[2-15/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG10-P[10-15/0.01]-L[10-20/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG12-P[12-16/0.01]-L[12-24/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG13-P[13-18/0.01]-L[13-26/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG16-P[16-25/0.01]-L[16-32/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAG20-P[20-30/0.01]-L[20-40/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH1-P[1-2.5/0.01]-L[2-3/1]-B[2-5/0.1]-E[0.5-10/0.1]-A[15,30,45,60] |

| BKFAAH2-P[2-4/0.01]-L[2-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH3-P[3-6/0.01]-L[3-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH4-P[4-7/0.01]-L[4-8/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH5-P[5-8/0.01]-L[5-10/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH6-P[6-10/0.01]-L[6-12/1]-B[2-12/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH8-P[8-13/0.01]-L[8-16/1]-B[2-15/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH10-P[10-15/0.01]-L[10-20/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH12-P[12-16/0.01]-L[12-24/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH13-P[13-18/0.01]-L[13-26/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH16-P[16-25/0.01]-L[16-32/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAH20-P[20-30/0.01]-L[20-40/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM1-P[1-2.5/0.01]-L[2-3/1]-B[2-5/0.1]-E[0.5-10/0.1]-A[15,30,45,60] |

| BKFAAM2-P[2-4/0.01]-L[2-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM3-P[3-6/0.01]-L[3-6/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM4-P[4-7/0.01]-L[4-8/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM5-P[5-8/0.01]-L[5-10/1]-B[2-10/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM6-P[6-10/0.01]-L[6-12/1]-B[2-12/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM8-P[8-13/0.01]-L[8-16/1]-B[2-15/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM10-P[10-15/0.01]-L[10-20/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM12-P[12-16/0.01]-L[12-24/1]-B[3-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM13-P[13-18/0.01]-L[13-26/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM16-P[16-25/0.01]-L[16-32/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| BKFAAM20-P[20-30/0.01]-L[20-40/1]-B[5-20/0.1]-E[0-10/0.1]-A[15,30,45,60] |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Inlet Side Tip Shape | Mounting Side Shape | Surface Treatment | Heat Treatment | Material | Steel Type | Stainless Steel Type | Locating Section Outer Dia. P (Ø) | Positioning Side O.D. Tolerance | Mounting Side Dia. D (Ø) | Mounting Side Outer Dia. Tolerance | Screw Dia. M (mm) | Mounting Section Length L (mm) | Positioning Part Length B (mm) | Taper Length E (mm) | A (°) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 1 ~ 2.5 | 0.005/0 | 1 | 0.005/0 | - | 2 ~ 3 | 2 ~ 5 | 0.5 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 2 ~ 4 | 0.005/0 | 2 | 0.005/0 | - | 2 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 3 ~ 6 | 0.005/0 | 3 | 0.005/0 | - | 3 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 4 ~ 7 | 0.005/0 | 4 | 0.005/0 | - | 4 ~ 8 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 5 ~ 8 | 0.005/0 | 5 | 0.005/0 | - | 5 ~ 10 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 6 ~ 10 | 0.005/0 | 6 | 0.005/0 | - | 6 ~ 12 | 2 ~ 12 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0.005/0 | 8 | 0.005/0 | - | 8 ~ 16 | 2 ~ 15 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 10 ~ 15 | 0.005/0 | 10 | 0.005/0 | - | 10 ~ 20 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 12 ~ 16 | 0.005/0 | 12 | 0.005/0 | - | 12 ~ 24 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 13 ~ 18 | 0.005/0 | 13 | 0.005/0 | - | 13 ~ 26 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 16 ~ 25 | 0.005/0 | 16 | 0.005/0 | - | 16 ~ 32 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 20 ~ 30 | 0.005/0 | 20 | 0.005/0 | - | 20 ~ 40 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 1 ~ 2.5 | 0/-0.005 | 1 | 0.005/0 | - | 2 ~ 3 | 2 ~ 5 | 0.5 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 2 ~ 4 | 0/-0.005 | 2 | 0.005/0 | - | 2 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 3 ~ 6 | 0/-0.005 | 3 | 0.005/0 | - | 3 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 4 ~ 7 | 0/-0.005 | 4 | 0.005/0 | - | 4 ~ 8 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 5 ~ 8 | 0/-0.005 | 5 | 0.005/0 | - | 5 ~ 10 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 6 ~ 10 | 0/-0.005 | 6 | 0.005/0 | - | 6 ~ 12 | 2 ~ 12 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.005 | 8 | 0.005/0 | - | 8 ~ 16 | 2 ~ 15 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 10 ~ 15 | 0/-0.005 | 10 | 0.005/0 | - | 10 ~ 20 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 12 ~ 16 | 0/-0.005 | 12 | 0.005/0 | - | 12 ~ 24 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 13 ~ 18 | 0/-0.005 | 13 | 0.005/0 | - | 13 ~ 26 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 16 ~ 25 | 0/-0.005 | 16 | 0.005/0 | - | 16 ~ 32 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 20 ~ 30 | 0/-0.005 | 20 | 0.005/0 | - | 20 ~ 40 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 1 ~ 2.5 | g6 | 1 | 0.005/0 | - | 2 ~ 3 | 2 ~ 5 | 0.5 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 2 ~ 4 | g6 | 2 | 0.005/0 | - | 2 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 3 ~ 6 | g6 | 3 | 0.005/0 | - | 3 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 4 ~ 7 | g6 | 4 | 0.005/0 | - | 4 ~ 8 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 5 ~ 8 | g6 | 5 | 0.005/0 | - | 5 ~ 10 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 6 ~ 10 | g6 | 6 | 0.005/0 | - | 6 ~ 12 | 2 ~ 12 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8 | 0.005/0 | - | 8 ~ 16 | 2 ~ 15 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 10 ~ 15 | g6 | 10 | 0.005/0 | - | 10 ~ 20 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 12 ~ 16 | g6 | 12 | 0.005/0 | - | 12 ~ 24 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 13 ~ 18 | g6 | 13 | 0.005/0 | - | 13 ~ 26 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 16 ~ 25 | g6 | 16 | 0.005/0 | - | 16 ~ 32 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 20 ~ 30 | g6 | 20 | 0.005/0 | - | 20 ~ 40 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 1 ~ 2.5 | h7 | 1 | 0.005/0 | - | 2 ~ 3 | 2 ~ 5 | 0.5 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 2 ~ 4 | h7 | 2 | 0.005/0 | - | 2 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 3 ~ 6 | h7 | 3 | 0.005/0 | - | 3 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 4 ~ 7 | h7 | 4 | 0.005/0 | - | 4 ~ 8 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 5 ~ 8 | h7 | 5 | 0.005/0 | - | 5 ~ 10 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 6 ~ 10 | h7 | 6 | 0.005/0 | - | 6 ~ 12 | 2 ~ 12 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8 | 0.005/0 | - | 8 ~ 16 | 2 ~ 15 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 10 ~ 15 | h7 | 10 | 0.005/0 | - | 10 ~ 20 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 12 ~ 16 | h7 | 12 | 0.005/0 | - | 12 ~ 24 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 13 ~ 18 | h7 | 13 | 0.005/0 | - | 13 ~ 26 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 16 ~ 25 | h7 | 16 | 0.005/0 | - | 16 ~ 32 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 20 ~ 30 | h7 | 20 | 0.005/0 | - | 20 ~ 40 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 1 ~ 2.5 | m6 | 1 | 0.005/0 | - | 2 ~ 3 | 2 ~ 5 | 0.5 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 2 ~ 4 | m6 | 2 | 0.005/0 | - | 2 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 3 ~ 6 | m6 | 3 | 0.005/0 | - | 3 ~ 6 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 4 ~ 7 | m6 | 4 | 0.005/0 | - | 4 ~ 8 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 5 ~ 8 | m6 | 5 | 0.005/0 | - | 5 ~ 10 | 2 ~ 10 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 6 ~ 10 | m6 | 6 | 0.005/0 | - | 6 ~ 12 | 2 ~ 12 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8 | 0.005/0 | - | 8 ~ 16 | 2 ~ 15 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 10 ~ 15 | m6 | 10 | 0.005/0 | - | 10 ~ 20 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 12 ~ 16 | m6 | 12 | 0.005/0 | - | 12 ~ 24 | 3 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 13 ~ 18 | m6 | 13 | 0.005/0 | - | 13 ~ 26 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 16 ~ 25 | m6 | 16 | 0.005/0 | - | 16 ~ 32 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Round | Straight(Press Fit) | Not Provided | No | Steel | Equivalent to SKS3 | - | 20 ~ 30 | m6 | 20 | 0.005/0 | - | 20 ~ 40 | 5 ~ 20 | 0 ~ 10 | 15 ~ 60 |

Loading...

Basic information

| Basic Shape | Large Head | Inlet Side Tip Type | Tapered | Inlet Style | No |

|---|

Configure

Basic Attributes

-

Mounting Side Shape

-

Straight(Press Fit)

Straight(Press Fit) -

Female Thread

Female Thread -

Male thread

Male thread

-

-

Surface Treatment

- Not Provided

- Hard Chrome Plating

-

Heat Treatment

- No

- Directly Quenched

-

Material

- Steel

- Stainless Steel

-

Steel Type

- Equivalent to SKS3

-

Stainless Steel Type

-

Locating Section Outer Dia. P(Ø)

-

Positioning Side O.D. Tolerance

-

Mounting Side Dia. D(Ø)

-

Mounting Side Outer Dia. Tolerance

-

Screw Dia. M(mm)

-

Mounting Section Length L(mm)

-

Positioning Part Length B(mm)

-

Taper Length E(mm)

-

A(°)

-

Type

- BKFAAA

- BKFAAB

- BKFAAG

- BKFAAH

- BKFAAM

- BKFAAP

- BKFAAS

- BKFABA

- BKFABB

- BKFABG

- BKFABH

- BKFABM

- BKFABP

- BKFABS

- BKFAGA

- BKFAGB

- BKFAGG

- BKFAGH

- BKFAGM

- BKFAGP

- BKFAGS

- BKFAHA

- BKFAHB

- BKFAHG

- BKFAHH

- BKFAHM

- BKFAHP

- BKFAHS

- BKFAMA

- BKFAMB

- BKFAMG

- BKFAMH

- BKFAMM

- BKFAMP

- BKFAMS

- BKFAPA

- BKFAPB

- BKFAPG

- BKFAPH

- BKFAPM

- BKFAPP

- BKFAPS

- BKFDAA

- BKFDAB

- BKFDAG

- BKFDAH

- BKFDAM

- BKFDAP

- BKFDAS

- BKFDBA

- BKFDBB

- BKFDBG

- BKFDBH

- BKFDBM

- BKFDBP

- BKFDBS

- BKFDGA

- BKFDGB

- BKFDGG

- BKFDGH

- BKFDGM

- BKFDGP

- BKFDGS

- BKFDHA

- BKFDHB

- BKFDHG

- BKFDHH

- BKFDHM

- BKFDHP

- BKFDHS

- BKFDMA

- BKFDMB

- BKFDMG

- BKFDMH

- BKFDMM

- BKFDMP

- BKFDMS

- BKFDPA

- BKFDPB

- BKFDPG

- BKFDPH

- BKFDPM

- BKFDPP

- BKFDPS

- BKFNAAA

- BKFNAAB

- BKFNAAG

- BKFNAAH

- BKFNAAM

- BKFNAAP

- BKFNAAS

- BKFNABA

- BKFNABB

- BKFNABG

- BKFNABH

- BKFNABM

- BKFNABP

- BKFNABS

- BKFNAGA

- BKFNAGB

- BKFNAGG

- BKFNAGH

- BKFNAGM

- BKFNAGP

- BKFNAGS

- BKFNAHA

- BKFNAHB

- BKFNAHG

- BKFNAHH

- BKFNAHM

- BKFNAHP

- BKFNAHS

- BKFNAMA

- BKFNAMB

- BKFNAMG

- BKFNAMH

- BKFNAMM

- BKFNAMP

- BKFNAMS

- BKFNAPA

- BKFNAPB

- BKFNAPG

- BKFNAPH

- BKFNAPM

- BKFNAPP

- BKFNAPS

- BKFTAGG

- BKFTAGH

- BKFTAGM

- BKFTAGP

- BKFTAGS

- BKFTAHG

- BKFTAHH

- BKFTAHM

- BKFTAHP

- BKFTAHS

- BKFTAMG

- BKFTAMH

- BKFTAMM

- BKFTAMP

- BKFTAMS

- BKFTAPG

- BKFTAPH

- BKFTAPM

- BKFTAPP

- BKFTAPS

- BKFTDGG

- BKFTDGH

- BKFTDGM

- BKFTDGP

- BKFTDGS

- BKFTDHG

- BKFTDHH

- BKFTDHM

- BKFTDHP

- BKFTDHS

- BKFTDMG

- BKFTDMH

- BKFTDMM

- BKFTDMP

- BKFTDMS

- BKFTDPG

- BKFTDPH

- BKFTDPM

- BKFTDPP

- BKFTDPS

- CKFAAA

- CKFAAB

- CKFAAG

- CKFAAH

- CKFAAM

- CKFAAP

- CKFAAS

- CKFABA

- CKFABB

- CKFABG

- CKFABH

- CKFABM

- CKFABP

- CKFABS

- CKFAGA

- CKFAGB

- CKFAGG

- CKFAGH

- CKFAGM

- CKFAGP

- CKFAGS

- CKFAHA

- CKFAHB

- CKFAHG

- CKFAHH

- CKFAHM

- CKFAHP

- CKFAHS

- CKFAMA

- CKFAMB

- CKFAMG

- CKFAMH

- CKFAMM

- CKFAMP

- CKFAMS

- CKFAPA

- CKFAPB

- CKFAPG

- CKFAPH

- CKFAPM

- CKFAPP

- CKFAPS

- CKFDAA

- CKFDAB

- CKFDAG

- CKFDAH

- CKFDAM

- CKFDAP

- CKFDAS

- CKFDBA

- CKFDBB

- CKFDBG

- CKFDBH

- CKFDBM

- CKFDBP

- CKFDBS

- CKFDGA

- CKFDGB

- CKFDGG

- CKFDGH

- CKFDGM

- CKFDGP

- CKFDGS

- CKFDHA

- CKFDHB

- CKFDHG

- CKFDHH

- CKFDHM

- CKFDHP

- CKFDHS

- CKFDMA

- CKFDMB

- CKFDMG

- CKFDMH

- CKFDMM

- CKFDMP

- CKFDMS

- CKFDPA

- CKFDPB

- CKFDPG

- CKFDPH

- CKFDPM

- CKFDPP

- CKFDPS

- CKFTAGG

- CKFTAGH

- CKFTAGM

- CKFTAGP

- CKFTAGS

- CKFTAHG

- CKFTAHH

- CKFTAHM

- CKFTAHP

- CKFTAHS

- CKFTAMG

- CKFTAMH

- CKFTAMM

- CKFTAMP

- CKFTAMS

- CKFTAPG

- CKFTAPH

- CKFTAPM

- CKFTAPP

- CKFTAPS

- CKFTDGG

- CKFTDGH

- CKFTDGM

- CKFTDGP

- CKFTDGS

- CKFTDHG

- CKFTDHH

- CKFTDHM

- CKFTDHP

- CKFTDHS

- CKFTDMG

- CKFTDMH

- CKFTDMM

- CKFTDMP

- CKFTDMS

- CKFTDPG

- CKFTDPH

- CKFTDPM

- CKFTDPP

- CKFTDPS

- GKFAGG

- GKFAGH

- GKFAGM

- GKFAGP

- GKFAGS

- GKFAHG

- GKFAHH

- GKFAHM

- GKFAHP

- GKFAHS

- GKFAMG

- GKFAMH

- GKFAMM

- GKFAMP

- GKFAMS

- GKFAPG

- GKFAPH

- GKFAPM

- GKFAPP

- GKFAPS

- GKFDGG

- GKFDGH

- GKFDGM

- GKFDGP

- GKFDGS

- GKFDHG

- GKFDHH

- GKFDHM

- GKFDHP

- GKFDHS

- GKFDMG

- GKFDMH

- GKFDMM

- GKFDMP

- GKFDMS

- GKFDPG

- GKFDPH

- GKFDPM

- GKFDPP

- GKFDPS

- GKFNAGG

- GKFNAGH

- GKFNAGM

- GKFNAGP

- GKFNAGS

- GKFNAHG

- GKFNAHH

- GKFNAHM

- GKFNAHP

- GKFNAHS

- GKFNAMG

- GKFNAMH

- GKFNAMM

- GKFNAMP

- GKFNAMS

- GKFNAPG

- GKFNAPH

- GKFNAPM

- GKFNAPP

- GKFNAPS

- GKFNDGG

- GKFNDGH

- GKFNDGM

- GKFNDGP

- GKFNDGS

- GKFNDHG

- GKFNDHH

- GKFNDHM

- GKFNDHP

- GKFNDHS

- GKFNDMG

- GKFNDMH

- GKFNDMM

- GKFNDMP

- GKFNDMS

- GKFNDPG

- GKFNDPH

- GKFNDPM

- GKFNDPP

- GKFNDPS

- GKFTAGG

- GKFTAGH

- GKFTAGM

- GKFTAGP

- GKFTAGS

- GKFTAHG

- GKFTAHH

- GKFTAHM

- GKFTAHP

- GKFTAHS

- GKFTAMG

- GKFTAMH

- GKFTAMM

- GKFTAMP

- GKFTAMS

- GKFTAPG

- GKFTAPH

- GKFTAPM

- GKFTAPP

- GKFTAPS

- GKFTDGG

- GKFTDGH

- GKFTDGM

- GKFTDGP

- GKFTDGS

- GKFTDHG

- GKFTDHH

- GKFTDHM

- GKFTDHP

- GKFTDHS

- GKFTDMG

- GKFTDMH

- GKFTDMM

- GKFTDMP

- GKFTDMS

- GKFTDPG

- GKFTDPH

- GKFTDPM

- GKFTDPP

- GKFTDPS

- HKFA□□

- HKFD□□

- HKFNA□□

- HKFNDGG

- HKFNDGH

- HKFNDGM

- HKFNDGP

- HKFNDGS

- HKFNDHG

- HKFNDHH

- HKFNDHM

- HKFNDHP

- HKFNDHS

- HKFNDMG

- HKFNDMH

- HKFNDMM

- HKFNDMP

- HKFNDMS

- HKFNDPG

- HKFNDPH

- HKFNDPM

- HKFNDPP

- HKFNDPS

- HKFTAGG

- HKFTAGH

- HKFTAGM

- HKFTAGP

- HKFTAGS

- HKFTAHG

- HKFTAHH

- HKFTAHM

- HKFTAHP

- HKFTAHS

- HKFTAMG

- HKFTAMH

- HKFTAMM

- HKFTAMP

- HKFTAMS

- HKFTAPG

- HKFTAPH

- HKFTAPM

- HKFTAPP

- HKFTAPS

- HKFTDGG

- HKFTDGH

- HKFTDGM

- HKFTDGP

- HKFTDGS

- HKFTDHG

- HKFTDHH

- HKFTDHM

- HKFTDHP

- HKFTDHS

- HKFTDMG

- HKFTDMH

- HKFTDMM

- HKFTDMP

- HKFTDMS

- HKFTDPG

- HKFTDPH

- HKFTDPM

- HKFTDPP

- HKFTDPS

- KFAAA

- KFAAB

- KFAAG

- KFAAH

- KFAAM

- KFAAP

- KFAAS

- KFABA

- KFABB

- KFABG

- KFABH

- KFABM

- KFABP

- KFABS

- KFAGA

- KFAGB

- KFAGG

- KFAGH

- KFAGM

- KFAGP

- KFAGS

- KFAHA

- KFAHB

- KFAHG

- KFAHH

- KFAHM

- KFAHP

- KFAHS

- KFAMA

- KFAMB

- KFAMG

- KFAMH

- KFAMM

- KFAMP

- KFAMS

- KFAPA

- KFAPB

- KFAPG

- KFAPH

- KFAPM

- KFAPP

- KFAPS

- KFDAA

- KFDAB

- KFDAG

- KFDAH

- KFDAM

- KFDAP

- KFDAS

- KFDBA

- KFDBB

- KFDBG

- KFDBH

- KFDBM

- KFDBP

- KFDBS

- KFDGA

- KFDGB

- KFDGG

- KFDGH

- KFDGM

- KFDGP

- KFDGS

- KFDHA

- KFDHB

- KFDHG

- KFDHH

- KFDHM

- KFDHP

- KFDHS

- KFDMA

- KFDMB

- KFDMG

- KFDMH

- KFDMM

- KFDMP

- KFDMS

- KFDPA

- KFDPB

- KFDPG

- KFDPH

- KFDPM

- KFDPP

- KFDPS

- KFNAAA

- KFNAAB

- KFNAAG

- KFNAAH

- KFNAAM

- KFNAAP

- KFNAAS

- KFNABA

- KFNABB

- KFNABG

- KFNABH

- KFNABM

- KFNABP

- KFNABS

- KFNAGA

- KFNAGB

- KFNAGG

- KFNAGH

- KFNAGM

- KFNAGP

- KFNAGS

- KFNAHA

- KFNAHB

- KFNAHG

- KFNAHH

- KFNAHM

- KFNAHP

- KFNAHS

- KFNAMA

- KFNAMB

- KFNAMG

- KFNAMH

- KFNAMM

- KFNAMP

- KFNAMS

- KFNAPA

- KFNAPB

- KFNAPG

- KFNAPH

- KFNAPM

- KFNAPP

- KFNAPS

- KFNDAA

- KFNDAB

- KFNDAG

- KFNDAH

- KFNDAM

- KFNDAP

- KFNDAS

- KFNDBA

- KFNDBB

- KFNDBG

- KFNDBH

- KFNDBM

- KFNDBP

- KFNDBS

- KFNDGA

- KFNDGB

- KFNDGG

- KFNDGH

- KFNDGM

- KFNDGP

- KFNDGS

- KFNDHA

- KFNDHB

- KFNDHG

- KFNDHH

- KFNDHM

- KFNDHP

- KFNDHS

- KFNDMA

- KFNDMB

- KFNDMG

- KFNDMH

- KFNDMM

- KFNDMP

- KFNDMS

- KFNDPA

- KFNDPB

- KFNDPG

- KFNDPH

- KFNDPM

- KFNDPP

- KFNDPS

- KFTAGG

- KFTAGH

- KFTAGM

- KFTAGP

- KFTAGS

- KFTAHG

- KFTAHH

- KFTAHM

- KFTAHP

- KFTAHS

- KFTAMG

- KFTAMH

- KFTAMM

- KFTAMP

- KFTAMS

- KFTAPG

- KFTAPH

- KFTAPM

- KFTAPP

- KFTAPS

- KFTDGG

- KFTDGH

- KFTDGM

- KFTDGP

- KFTDGS

- KFTDHG

- KFTDHH

- KFTDHM

- KFTDHP

- KFTDHS

- KFTDMG

- KFTDMH

- KFTDMM

- KFTDMP

- KFTDMS

- KFTDPG

- KFTDPH

- KFTDPM

- KFTDPP

- KFTDPS

- SKFAAA

- SKFAAB

- SKFAAG

- SKFAAH

- SKFAAM

- SKFAAP

- SKFAAS

- SKFABA

- SKFABB

- SKFABG

- SKFABH

- SKFABM

- SKFABP

- SKFABS

- SKFAGA

- SKFAGB

- SKFAGG

- SKFAGH

- SKFAGM

- SKFAGP

- SKFAGS

- SKFAHA

- SKFAHB

- SKFAHG

- SKFAHH

- SKFAHM

- SKFAHP

- SKFAHS

- SKFAMA

- SKFAMB

- SKFAMG

- SKFAMH

- SKFAMM

- SKFAMP

- SKFAMS

- SKFAPA

- SKFAPB

- SKFAPG

- SKFAPH

- SKFAPM

- SKFAPP

- SKFAPS

- SKFDAA

- SKFDAB

- SKFDAG

- SKFDAH

- SKFDAM

- SKFDAP

- SKFDAS

- SKFDBA

- SKFDBB

- SKFDBG

- SKFDBH

- SKFDBM

- SKFDBP

- SKFDBS

- SKFDGA

- SKFDGB

- SKFDGG

- SKFDGH

- SKFDGM

- SKFDGP

- SKFDGS

- SKFDHA

- SKFDHB

- SKFDHG

- SKFDHH

- SKFDHM

- SKFDHP

- SKFDHS

- SKFDMA

- SKFDMB

- SKFDMG

- SKFDMH

- SKFDMM

- SKFDMP

- SKFDMS

- SKFDPA

- SKFDPB

- SKFDPG

- SKFDPH

- SKFDPM

- SKFDPP

- SKFDPS

- SKFNAAA

- SKFNAAB

- SKFNAAG

- SKFNAAH

- SKFNAAM

- SKFNAAP

- SKFNAAS

- SKFNABA

- SKFNABB

- SKFNABG

- SKFNABH

- SKFNABM

- SKFNABP

- SKFNABS

- SKFNAGA

- SKFNAGB

- SKFNAGG

- SKFNAGH

- SKFNAGM

- SKFNAGP

- SKFNAGS

- SKFNAHA

- SKFNAHB

- SKFNAHG

- SKFNAHH

- SKFNAHM

- SKFNAHP

- SKFNAHS

- SKFNAMA

- SKFNAMB

- SKFNAMG

- SKFNAMH

- SKFNAMM

- SKFNAMP

- SKFNAMS

- SKFNAPA

- SKFNAPB

- SKFNAPG

- SKFNAPH

- SKFNAPM

- SKFNAPP

- SKFNAPS

- SKFNDAA

- SKFNDAB

- SKFNDAG

- SKFNDAH

- SKFNDAM

- SKFNDAP

- SKFNDAS

- SKFNDBA

- SKFNDBB

- SKFNDBG

- SKFNDBH

- SKFNDBM

- SKFNDBP

- SKFNDBS

- SKFNDGA

- SKFNDGB

- SKFNDGG

- SKFNDGH

- SKFNDGM

- SKFNDGP

- SKFNDGS

- SKFNDHA

- SKFNDHB

- SKFNDHG

- SKFNDHH

- SKFNDHM

- SKFNDHP

- SKFNDHS

- SKFNDMA

- SKFNDMB

- SKFNDMG

- SKFNDMH

- SKFNDMM

- SKFNDMP

- SKFNDMS

- SKFNDPA

- SKFNDPB

- SKFNDPG

- SKFNDPH

- SKFNDPM

- SKFNDPP

- SKFNDPS

- SKFTAGG

- SKFTAGH

- SKFTAGM

- SKFTAGP

- SKFTAGS

- SKFTAHG

- SKFTAHH

- SKFTAHM

- SKFTAHP

- SKFTAHS

- SKFTAMG

- SKFTAMH

- SKFTAMM

- SKFTAMP

- SKFTAMS

- SKFTAPG

- SKFTAPH

- SKFTAPM

- SKFTAPP

- SKFTAPS

- SKFTDGG

- SKFTDGH

- SKFTDGM

- SKFTDGP

- SKFTDGS

- SKFTDHG

- SKFTDHH

- SKFTDHM

- SKFTDHP

- SKFTDHS

- SKFTDMG

- SKFTDMH

- SKFTDMM

- SKFTDMP

- SKFTDMS

- SKFTDPG

- SKFTDPH

- SKFTDPM

- SKFTDPP

- SKFTDPS

-

Inlet Side Tip Shape

-

Round

Round -

Diamond

Diamond

-

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 6 Days or Less

- 7 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)