- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 3:00 21/4/2024 to 0:00 (CET) 22/4/2024. We apologize for the inconvenience.

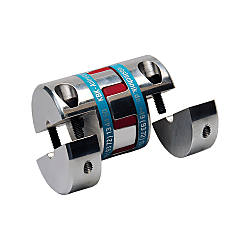

Claw couplings / half-shell clamping, feather key DIN 6885 / claw disc: PU, Shore A98 / body: aluminium / KBE2H / KBK

· For shaft diameters from 4 - 55mm

· Vibration reducing, compensates shaft misalignment, axial pluggable!

· Characteristics of the coupling can be modified by using different spider elements!

· Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling

· Torque range: 12,5 - 525Nm

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

Servo Insert Coupling with split hubs, KBE2H | 14 ~ 55

Product Information

Material

spider element - polyurethane

Hub

Keyway

All series are available with loose-fit spiders (see catalog).

Drawing

Order Code

| Order Code | KBE2H | - | 19 | - | 10 | - | 12 | - | 98Sh | ||

| Type | Size | ØD1 (H7) | ØD2 (H7) | Shore- hardness |

Specification Table

| Size | Dimensions (mm) | Technical Data | Torque (Nm) | |||||||||||||||

| Ø A | L | Ø D1/D2 | E | W | F | C | B | H | K | G Screw (ISO4762) TA (Nm) | max. speed rpm. (1/min) | Mass (per coupling) (g) | Moment of Inertia J (per coupling) (g m2) | 64 ShoreD (green) | 98 ShoreA (red) | 92 ShoreA (yellow) | 80 ShoreA (blue) | |

| Outer Ø | Length | Bore Sizes (H7) min~max | ||||||||||||||||

| 9 | 20 | 30 | 4 - 11 | 10 | 14 | 10 | 5 | 23.5 | 7 | 8 | M2.5 | 19000 | 20 | 0.00121 | 6 | 5 | 3 | 1.8 |

| 0.85 | ||||||||||||||||||

| 12 | 25 | 34 | 4 - 12 | 11 | 18 | 12 | 5 | 27.2 | 8.25 | 8 | M3 | 16000 | 36 | 0.00354 | 12 | 9 | 5 | 3 |

| 2 | ||||||||||||||||||

| 14 | 30 | 35 | 4 - 16 | 11 | 19 | 13 | 5.0 | 35 | 10.5 | 8 | M4 | 13000 | 50 | 0.007 | 16 | 12.5 | 7.5 | 4 |

| 5 | ||||||||||||||||||

| 19 | 40 | 66 | 8 - 21 | 25 | 27 | 16 | 8.0 | 46 | 14.5 | 19.5 | M6 | 10000 | 182 | 0.042 | 26 | 21 | 12 | 6 |

| 15 | ||||||||||||||||||

| 24 | 55 | 78 | 10 - 32 | 30 | 34 | 18 | 10.5 | 57.5 | 20 | 22.0 | M6 | 7000 | 391 | 0.171 | 75 | 60 | 35 | 17 |

| 15 | ||||||||||||||||||

| 28 | 65 | 90 | 14 - 37 | 35 | 40 | 20 | 11.5 | 73 | 25 | 25.0 | M8 | 6000 | 643 | 0.402 | 200 | 160 | 95 | 46 |

| 40 | ||||||||||||||||||

| 38 | 80 | 114 | 18 - 48 | 45 | 48 | 24 | 15.5 | 83.5 | 30 | 33.0 | M8 | 5000 | 1167 | 1.096 | 405 | 325 | 190 | x |

| 40 | ||||||||||||||||||

| 42 | 95 | 126 | 22 - 50 | 50 | 53 | 26 | 18.0 | 93.5 | 32 | 36.5 | M10 | 4000 | 1943 | 2.522 | 560 | 450 | 265 | x |

| 84 | ||||||||||||||||||

| 48 | 105 | 140 | 22 - 57 | 56 | 61 | 28 | 18.5 | 105 | 36 | 39.5 | M12 | 3750 | 2592 | 4.076 | 655 | 525 | 310 | x |

| 145 | ||||||||||||||||||

| 55 | 120 | 160 | 25 - 74 | 65 | 70 | 30 | 26 | 122.8 | 45 | 45 | M12 | 3500 | 3260 | 7.349 | 825 | 685 | 410 | x |

| 145 | ||||||||||||||||||

| Transmittable torque (Nm) depending on shaft diameter (mm) | ||||||||||||||||||||||||||||

| Size | 4 | 6 | 8 | 10 | 14 | 15 | 16 | 18 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 58 | 60 | 65 | 70 | 74 |

| 9 | 3 | 4 | 6 | 7 | ||||||||||||||||||||||||

| 12 | 6 | 9 | 12 | 15 | 21 | 22 | 24 | |||||||||||||||||||||

| 14 | 11 | 16 | 21 | 26 | 37 | 39 | 42 | |||||||||||||||||||||

| 19 | 47 | 59 | 83 | 89 | 95 | 107 | 119 | |||||||||||||||||||||

| 24 | 59 | 83 | 89 | 95 | 107 | 119 | 130 | 142 | 148 | 166 | 178 | 190 | ||||||||||||||||

| 28 | 123 | 132 | 141 | 159 | 176 | 194 | 211 | 220 | 247 | 264 | 282 | 308 | ||||||||||||||||

| 38 | 159 | 176 | 194 | 211 | 220 | 247 | 264 | 282 | 308 | 335 | 352 | 370 | 396 | 423 | ||||||||||||||

| 42 | 370 | 404 | 420 | 471 | 505 | 538 | 589 | 639 | 673 | 706 | 757 | 807 | 841 | |||||||||||||||

| 48 | 539 | 588 | 612 | 686 | 735 | 784 | 857 | 931 | 980 | 1029 | 1102 | 1176 | 1225 | 1347 | ||||||||||||||

| 55 | 612 | 686 | 735 | 784 | 857 | 931 | 980 | 1029 | 1102 | 1176 | 1225 | 1347 | 1421 | 1470 | 1592 | 1715 | 1813 | |||||||||||

Part Number

|

|---|

| KBE2H-14-[4-16/1]-[4-16/1] |

| KBE2H-14-[4-16/1]-N[4-16/1] |

| KBE2H-14-N[4-16/1]-[4-16/1] |

| KBE2H-14-N[4-16/1]-N[4-16/1] |

| KBE2H-19-[8-21/1]-[8-21/1] |

| KBE2H-19-[8-21/1]-N[8-21/1] |

| KBE2H-19-N[8-21/1]-[8-21/1] |

| KBE2H-19-N[8-21/1]-N[8-21/1] |

| KBE2H-24-[10-32/1]-[10-32/1] |

| KBE2H-24-[10-32/1]-N[10-32/1] |

| KBE2H-24-N[10-32/1]-[10-32/1] |

| KBE2H-24-N[10-32/1]-N[10-32/1] |

| KBE2H-28-[14-37/1]-[14-37/1] |

| KBE2H-28-[14-37/1]-N[14-37/1] |

| KBE2H-28-N[14-37/1]-[14-37/1] |

| KBE2H-28-N[14-37/1]-N[14-37/1] |

| KBE2H-38-[18-48/1]-[18-48/1] |

| KBE2H-38-[18-48/1]-N[18-48/1] |

| KBE2H-38-N[18-48/1]-[18-48/1] |

| KBE2H-38-N[18-48/1]-N[18-48/1] |

| KBE2H-42-[22-50/1]-[22-50/1] |

| KBE2H-42-[22-50/1]-N[22-50/1] |

| KBE2H-42-N[22-50/1]-[22-50/1] |

| KBE2H-42-N[22-50/1]-N[22-50/1] |

| KBE2H-48-[22-57/1]-[22-57/1] |

| KBE2H-48-[22-57/1]-N[22-57/1] |

| KBE2H-48-N[22-57/1]-[22-57/1] |

| KBE2H-48-N[22-57/1]-N[22-57/1] |

| Part Number | Related to |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Shaft Bore Dia. (machined) D1 (mm) | Shaft Bore Dia. (machined) D2 (mm) | Outer Dia. A (mm) | Length L (mm) | Allowable Torque (Nm) | Max. Rotational Speed (r/min) | Allowable Lateral Misalignment (mm) | Allowable Axial Clearance (±) (mm) | Applicable Range (Bore 1) | Applicable Range (Bore 2) | Maximum D1 Bore Size with Keyway | Maximum D2 Bore Size with Keyway | Keyway (D1) | Keyway (D2) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 12 Days | 10 | 4 ~ 16 | 4 ~ 16 | 30 | 35 | 12.5 | 13000 | 0.09 | 1 | 4-14 | 4-14 | 14 | 14 | No | No | |||

- | 1 | 12 Days | 10 | 4 ~ 16 | 4 ~ 16 | 30 | 35 | 12.5 | 13000 | 0.09 | 1 | 4-14 | 4-14 | 14 | 14 | No | Yes | |||

- | 1 | 12 Days | 10 | 4 ~ 16 | 4 ~ 16 | 30 | 35 | 12.5 | 13000 | 0.09 | 1 | 4-14 | 4-14 | 14 | 14 | Yes | No | |||

- | 1 | 12 Days | 10 | 4 ~ 16 | 4 ~ 16 | 30 | 35 | 12.5 | 13000 | 0.09 | 1 | 4-14 | 4-14 | 14 | 14 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 8 ~ 21 | 8 ~ 21 | 40 | 66 | 17 | 10000 | 0.06 | 1.2 | 8-20 | 8-20 | 20 | 20 | No | No | |||

- | 1 | 12 Days | 10 | 8 ~ 21 | 8 ~ 21 | 40 | 66 | 17 | 10000 | 0.06 | 1.2 | 8-20 | 8-20 | 20 | 20 | No | Yes | |||

- | 1 | 12 Days | 10 | 8 ~ 21 | 8 ~ 21 | 40 | 66 | 17 | 10000 | 0.06 | 1.2 | 8-20 | 8-20 | 20 | 20 | Yes | No | |||

- | 1 | 12 Days | 10 | 8 ~ 21 | 8 ~ 21 | 40 | 66 | 17 | 10000 | 0.06 | 1.2 | 8-20 | 8-20 | 20 | 20 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 10 ~ 32 | 10 ~ 32 | 55 | 78 | 60 | 7000 | 0.1 | 1.4 | 10-30 | 10-30 | 30 | 30 | No | No | |||

- | 1 | 12 Days | 10 | 10 ~ 32 | 10 ~ 32 | 55 | 78 | 60 | 7000 | 0.1 | 1.4 | 10-30 | 10-30 | 30 | 30 | No | Yes | |||

- | 1 | 12 Days | 10 | 10 ~ 32 | 10 ~ 32 | 55 | 78 | 60 | 7000 | 0.1 | 1.4 | 10-30 | 10-30 | 30 | 30 | Yes | No | |||

- | 1 | 12 Days | 10 | 10 ~ 32 | 10 ~ 32 | 55 | 78 | 60 | 7000 | 0.1 | 1.4 | 10-30 | 10-30 | 30 | 30 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 14 ~ 37 | 14 ~ 37 | 65 | 90 | 160 | 6000 | 0.11 | 1.5 | 14-38 | 14-38 | 38 | 38 | No | No | |||

- | 1 | 12 Days | 10 | 14 ~ 37 | 14 ~ 37 | 65 | 90 | 160 | 6000 | 0.11 | 1.5 | 14-38 | 14-38 | 38 | 38 | No | Yes | |||

- | 1 | 12 Days | 10 | 14 ~ 37 | 14 ~ 37 | 65 | 90 | 160 | 6000 | 0.11 | 1.5 | 14-38 | 14-38 | 38 | 38 | Yes | No | |||

- | 1 | 12 Days | 10 | 14 ~ 37 | 14 ~ 37 | 65 | 90 | 160 | 6000 | 0.11 | 1.5 | 14-38 | 14-38 | 38 | 38 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 18 ~ 48 | 18 ~ 48 | 80 | 114 | 325 | 5000 | 0.12 | 1.8 | 18-45 | 18-45 | 45 | 45 | No | No | |||

- | 1 | 12 Days | 10 | 18 ~ 48 | 18 ~ 48 | 80 | 114 | 325 | 5000 | 0.12 | 1.8 | 18-45 | 18-45 | 45 | 45 | No | Yes | |||

- | 1 | 12 Days | 10 | 18 ~ 48 | 18 ~ 48 | 80 | 114 | 325 | 5000 | 0.12 | 1.8 | 18-45 | 18-45 | 45 | 45 | Yes | No | |||

- | 1 | 12 Days | 10 | 18 ~ 48 | 18 ~ 48 | 80 | 114 | 325 | 5000 | 0.12 | 1.8 | 18-45 | 18-45 | 45 | 45 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 22 ~ 50 | 22 ~ 50 | 95 | 126 | 450 | 4000 | 0.14 | 2 | 22-50 | 22-50 | 50 | 50 | No | No | |||

- | 1 | 12 Days | 10 | 22 ~ 50 | 22 ~ 50 | 95 | 126 | 450 | 4000 | 0.14 | 2 | 22-50 | 22-50 | 50 | 50 | No | Yes | |||

- | 1 | 12 Days | 10 | 22 ~ 50 | 22 ~ 50 | 95 | 126 | 450 | 4000 | 0.14 | 2 | 22-50 | 22-50 | 50 | 50 | Yes | No | |||

- | 1 | 12 Days | 10 | 22 ~ 50 | 22 ~ 50 | 95 | 126 | 450 | 4000 | 0.14 | 2 | 22-50 | 22-50 | 50 | 50 | Yes | Yes | |||

- | 1 | 12 Days | 10 | 22 ~ 57 | 22 ~ 57 | 105 | 140 | 525 | 3750 | 0.16 | 2.1 | 22-55 | 22-55 | 55 | 55 | No | No | |||

- | 1 | 12 Days | 10 | 22 ~ 57 | 22 ~ 57 | 105 | 140 | 525 | 3750 | 0.16 | 2.1 | 22-55 | 22-55 | 55 | 55 | No | Yes | |||

- | 1 | 12 Days | 10 | 22 ~ 57 | 22 ~ 57 | 105 | 140 | 525 | 3750 | 0.16 | 2.1 | 22-55 | 22-55 | 55 | 55 | Yes | No | |||

- | 1 | 12 Days | 10 | 22 ~ 57 | 22 ~ 57 | 105 | 140 | 525 | 3750 | 0.16 | 2.1 | 22-55 | 22-55 | 55 | 55 | Yes | Yes |

Loading...

Basic information

| Type | Jaw Type | Application | Standard / Servo Motor / Stepping Motor / Encoder | Feature | High Torsional Rigidity / High Torque / High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation |

|---|---|---|---|---|---|

| Allowable Angular Misalignment(deg) | 0.9 | Buffer Part Material | Polyurethane |

Configure

Basic Attributes

-

Shaft Bore Dia. (machined) D1(mm)

-

Shaft Bore Dia. (machined) D2(mm)

-

Outer Dia. A(mm)

-

Length L(mm)

-

Allowable Torque(Nm)

-

Max. Rotational Speed(r/min)

-

Allowable Lateral Misalignment(mm)

-

Applicable Range (Bore 1)

-

Applicable Range (Bore 2)

-

Maximum D1 Bore Size with Keyway

-

Maximum D2 Bore Size with Keyway

-

Keyway (D1)

- No

- Yes

-

Keyway (D2)

- No

- Yes

-

Type

- KBE2H

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 12 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .