Additionally Processed End Mills (Carbide)(Machining Application:Inclined Cuts)

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

Configure now

Starting from∗ : 14.36 € Min. Shipping Days : 9 Days *Unit price with basic configuration

-

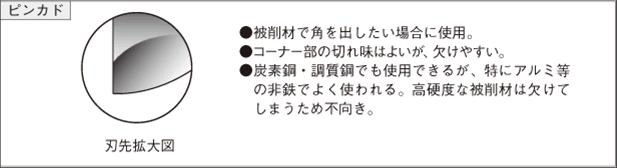

Carbide Roughing Alterations End Mill

MISUMI

A roughing end mill with 4 simultaneous locations that can be specified- Volume Discount

- TS

- General Steel

Configure nowStarting from∗ : 49.40 € Min. Shipping Days : 9 Days *Unit price with basic configuration

-

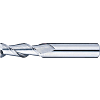

Carbide 2-Flute Square Alterations End Mill

MISUMI

Alterations end mill series with 6 simultaneous locations that can be specified- Volume Discount

- TS

- General Steel

- 2 Flutes

Configure nowStarting from∗ : 17.25 € Min. Shipping Days : 9 Days *Unit price with basic configuration

-

Carbide 4-Flute Square Alterations End Mill

MISUMI

A 4-flute end mill with 5 simultaneous locations that can be specified- Volume Discount

- General Steel

- 4 Flutes

Configure nowStarting from∗ : 21.01 € Min. Shipping Days : 9 Days *Unit price with basic configuration

-

Carbide 3 / 4-Flute Square Alterations End Mill

MISUMI

A multi-functional end mill with 4 simultaneous locations that can be specified- Volume Discount

- General Steel

Configure nowStarting from∗ : 17.34 € Min. Shipping Days : 9 Days *Unit price with basic configuration

-

Carbide Square Alterations End Mill for Aluminum, Copper and Resin Machining

MISUMI

An end mill for aluminum, copper and resin machining with 5 simultaneous locations that can be specified- Volume Discount

Configure nowStarting from∗ : 22.24 € Min. Shipping Days : 9 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days |

| Specifications |

| work material |

| Blade diameter (D)(φ) |

| Type |

| Blade length (ℓ)(mm) |

| Number of flutes(sheet) |

| Machining Application |

| Blade tip shape |

| Coating |

| Torsion Angle (θ) |

| Shank diameter (d)(mm) |

| Underneck length (ℓ1)(mm) |

| Overall Length (L)(mm) |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

|---|---|---|---|---|---|---|

| Product Series | Carbide Square Alterations End Mill for Aluminum, Copper and Resin Machining | |||||

| Starting from∗ | 14.36 € *Unit price with basic configuration Volume Discount | 49.40 € *Unit price with basic configuration Volume Discount | 17.25 € *Unit price with basic configuration Volume Discount | 21.01 € *Unit price with basic configuration Volume Discount | 17.34 € *Unit price with basic configuration Volume Discount | 22.24 € *Unit price with basic configuration Volume Discount |

| Min. Shipping Days | 9 Days | 9 Days | 9 Days | 9 Days | 9 Days | 9 Days |

| Specifications |

|

|

|

|

| |

| work material | General Steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○/◎] / Cast Iron[○] / Aluminum[○] / Copper[○] | Aluminum[○/◎] / Copper[○/◎] / Graphite[○] / Resin[○/◎] |

| Blade diameter (D)(φ) | 2 ~ 12 | 5 ~ 20 | 4 ~ 20 | 4 ~ 20 | 4 ~ 22 | 2 ~ 20 |

| Type | Square | Roughing | Square | Square | Square | Square |

| Blade length (ℓ)(mm) | 4 ~ 36 | 10 ~ 65 | 6 ~ 60 | 6 ~ 60 | 4 ~ 75 | 4 ~ 60 |

| Number of flutes(sheet) | 2 ~ 4 | 3 ~ 4 | 2 | 4 | 2 ~ 4 | 2 ~ 4 |

| Machining Application | Inclined Cuts | Inclined Cuts | Inclined Cuts | Inclined Cuts | Inclined Cuts | Inclined Cuts |

| Blade tip shape | With Lead | C plane / Micro R | Sharp Edge / With Lead | Sharp Edge / With Lead | Sharp Edge / With Lead | Sharp Edge / With Lead |

| Coating | Non-Coated | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | Non-Coated |

| Torsion Angle (θ) | Standard Helix (30˚ to 40˚) | Weak torsion (15˚ to 25˚) / High Helix (45˚ to 60˚) | Standard Helix (30˚ to 40˚) | Standard Helix (30˚ to 40˚) | Standard Helix (30˚ to 40˚) / High Helix (45˚ to 60˚) | Weak torsion (15˚ to 25˚) / Standard Helix (30˚ to 40˚) / High Helix (45˚ to 60˚) |

| Shank diameter (d)(mm) | 4 ~ 12 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 4 ~ 20 |

| Underneck length (ℓ1)(mm) | - | - | - | - | 35 ~ 140 | - |

| Overall Length (L)(mm) | 40 ~ 85 | 57 ~ 150 | 45 ~ 130 | 45 ~ 130 | 40 ~ 200 | 40 ~ 180 |

Loading...

Filter by:

-

work material

-

Blade diameter (D)(φ)

-

Type

- Square

- Roughing

-

Blade length (ℓ)(mm)

-

Number of flutes(sheet)

-

Machining Application

-

Blade tip shape

-

Coating

-

Torsion Angle (θ)

-

Shank diameter (d)(mm)

-

Underneck length (ℓ1)(mm)

-

Overall Length (L)(mm)

Brand

CAD data type

-

- 2D

- 3D