- No.

- 1223

- Shape

- Height (H)

- 41

- Height (h)

- 23

- Type

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 5 working days

Ball screw nut stops / pitch / PUA90 (BSTS1223)

Outline drawing and specifications table

BSTS

BSTP

BSTS

[ ! ] BSTS is a thin wall type.

[H] Hardness: Shore A90

Specification Table

| Part Number |

| BSTP15 |

| Part Number | B | H | h | P | V | BSTP | BSTS | |||||||||

| Type | No. | T | d1 | d2 | ℓ | Mass (g) | T1 | d3 | d4 | ℓ1 | Mass (g) | |||||

| BSTP BSTS (Thin wall) | 6 | 42 | 25 | 13 | 30 | 12 | 20 | 9.5 | 5.5 | 5.5 | 21 | 13 | 8 | 4.5 | 15 | 14 |

| 8 | 52 | 32 | 17 | 38 | 14 | 11 | 6.5 | 6.5 | 33 | 15 | 9.5 | 5.5 | 17 | 25 | ||

| 1022 | 70 | 40 | 22 | 52 | 16 | 25 | 14 | 9 | 9 | 74 | 18 | 11 | 6.5 | 23 | 54 | |

| 10 | 43 | 25 | 83 | 50 | ||||||||||||

| 1223 | 41 | 23 | 18 | 73 | 53 | |||||||||||

| 12 | 43 | 25 | 70 | 50 | ||||||||||||

| 1526 | 80 | 46 | 26 | 60 | 22 | 30 | 17 | 11 | 11 | 114 | 20 | 14 | 9 | 30 | 76 | |

| 1528 | 48 | 28 | 106 | 71 | ||||||||||||

| 15 | 50 | 30 | 110 | 73 | ||||||||||||

| 20 | 95 | 58 | 75 | 28 | 159 | 33 | 106 | |||||||||

| 25 | 105 | 68 | 35 | 85 | 35 | 189 | 38 | 134 | ||||||||

More Information

Basic information

It can be used as a mechanical stopper for recirculating ball screws.

Outline and specifications

App. Example

General Information - Ball Screws

Ball Screw Selection Details

- Material: steel

- Coatings: uncoated, LTBC coating, phosphate conversion coating

- Heat treatment: up to 62HRC

- Precision category: C3, C5, C7, C10

- Precision classes: precision class, standard class

- Slope: 1 to 32 mm

- Outer diameter: 6 to 32 mm

- Length (mm): 100 to 2000

- Nut shape: round flange, square flange, compact flange, block shape

Description/Basics

Ball screws are intended for converting rotary motion to linear motion. This can also be done in reverse order from linear to rotary motion. With the ball screws, this is achieved extremely precisely due to their low play. In mechanical engineering, the ball thread drive is an indispensable feature and is indispensable in precision applications. These work in horizontal and vertical orientation, allowing to shift, raise and lower devices.

The ball screws are often driven by motors and shaft couplings, or manually via rotary/crank handles.

When utilising a keyway, it is recommended using a machine key, as these can be combined excellently due to the manufacturing tolerances.

For a smooth process, it is recommended installing the ball screw with a fixed bearing and a floating bearing. This ensures that the ball screw does not bend due to compression and generate vibrations. For this purpose, MISUMI offers the right support units drives in various designs. For more information on how to install ball screws, see the Installation Instructions available as a PDF.

Ball screw nuts are available in different shapes. These enable versatile utilisation, even in confined spaces. Due to their high precision, the ball screws can also provide a high level of repeatability that is necessary in precise positioning applications. These can be utilised, for example, for measuring devices or in 3D printing. It is recommended to use a pre-stressed ball screw for highly precise applications. Due to the pre-tensioning, the axial play is almost zero unlike a conventional ball screw. In addition, MISUMI offers single axis actuators (locating units) for such applications, which as drives are already equipped with precise ball screws.

In smaller applications, a slide screw or a so-called miniature screw drive can be used. Due to their design, these are very compact, but suitable for lower axial loads.

If very high forces occur, a lead screw could also be considered.

Which ball screw is the right one for your application must be calculated based on the existing factors and influences. You can use the selection Ball Screws that is available as a PDF for this purpose. You can also find the service life calculation in this link.

Application Examples - Ball Screws

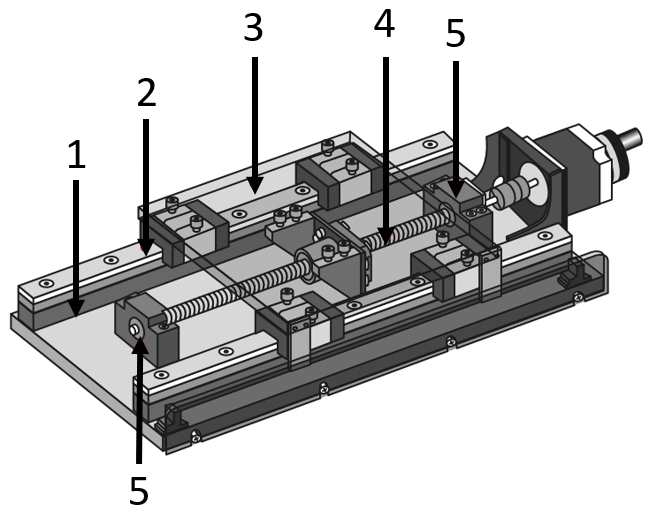

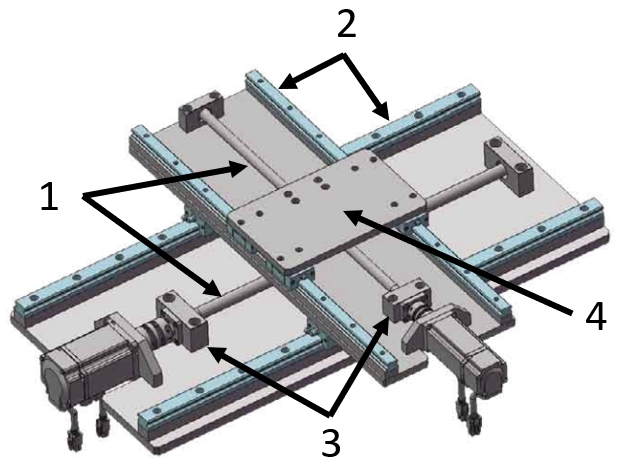

Application example for positioning stages

(1) Linear guide accessories, (2) Standard linear guide, (3) Table plate (meviy), (4) Ball screw, (5) Support units

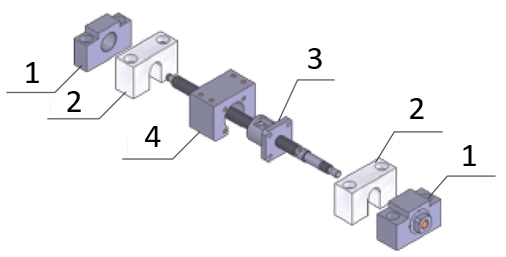

Application example for the ball screw

(1)) Support units, (2) Ball screw nut stops, (3) Ball screw, (4) Ball screw nut mountings

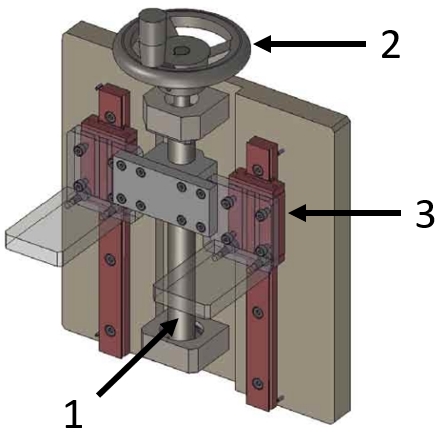

Application example for a lifting device

(1) Ball screw, (2) Standard linear guide, (3) Support units, (4) Table top (meviy)

(1) Ball screw, (2) Standard linear guide, (3) Support units, (4) Table top (meviy)

Industrial Applications