- Inner Diameter(mm)[4-25/0.01mm units]

- Outer Diameter(mm)

- 8

- 10

- 12

- 15

- 18

- 20

- 22

- 25

- 26

- 30

- 35

- Outer Diameter Tolerance

- Material

- Steel

- EN 1.2510 Equiv.

- Surface Treatment

- Length L(mm)[8-50/0.1mm units]

- Type

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 14 working days

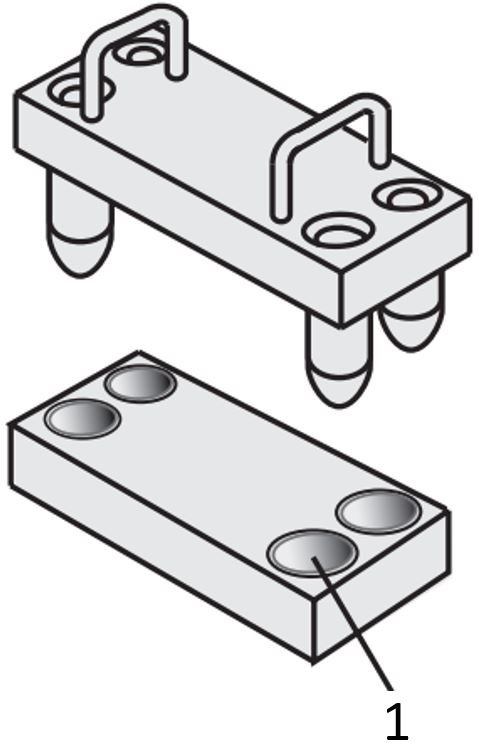

Flanged drill bushes / groove / Bore +0.01 / steel, stainless steel / 50HRC, 60HRC

Part number:

possible part numbers found.Outline drawing and specifications table

[ ! ]

| D | p6 | m6 | h6 |

| 8 | +0.024 +0.015 | +0.015 +0.006 | 0 |

| 10 | |||

| 12 | +0.029 +0.018 | +0.018 +0.007 | 0 |

| 15 | |||

| 18 | |||

| 20 | +0.035 +0.022 | +0.021 +0.008 | 0 |

| 22 | |||

| 25 | |||

| 26 | |||

| 30 | |||

| 35 | +0.042 +0.026 | +0.025 +0.009 | 0 |

[ ! ] For hole machining, please note that inner diameter shrinkage of p6 Type is larger than that of m6 Type.

| [M] Material | [S] Surface Treatment | [H] Hardness | Type | ||

| p6 | m6 | h6 | |||

| EN 1.2510 Equiv. | — | 56 to 60HRC | JBHFPG | JBHFG | JBHG |

| Electroless Nickel Plating | 56 to 60HRC | JBHFMPG | JBHFMG | JBHMG | |

| EN 1.4037 Equiv. | — | 50 to 55HRC | JBHFCPG | JBHFCG | — |

Specification Table

| Part Number | — | P | — | W | — | L |

| JBAFG8 JBHG20 JBHFYG18 JBFR10 JBPE10 | — — — — — | P4.1 P13.0 P12.00 P6.0 P6.8 | — — | W4.5 W4.8 | — — — — — | L11 L20 L18.0 L10 L15 |

| Part Number | P 0.01 mm Increments | L 0.1 mm Increments | Thickness (N) | R | H | T | |

| Type | D | ||||||

| (p6) JBHFPG JBHFMPG JBHFCPG (m6) JBHFG JBHFMG JBHFCG (h6) JBHG JBHMG | 8 | 4.00 to 4.50 | 8.0 to 10.0 | 1.75 to 2.50 | 1.0 | 12 | 3 |

| 10 | 4.00 to 6.50 | 8.0 to 15.0 | 1.75 to 3.00 | 14 | |||

| 12 | 6.00 to 8.50 | 2.0 | 16 | 4 | |||

| 15 | 8.00 to 10.50 | 10.0 to 35.0 | 2.25 to 3.50 | 19 | |||

| 18 | 10.00 to 12.50 | 2.75 to 4.00 | 22 | ||||

| 20 | 12.00 to 13.50 | 3.25 to 4.00 | 26 | 5 | |||

| 22 | 12.00 to 13.50 | 4.25 to 5.00 | |||||

| 25 | 13.00 to 15.50 | 4.75 to 6.00 | 30 | ||||

| 26 | 15.00 to 16.50 | 4.75 to 5.50 | |||||

| 30 | 16.00 to 20.50 | 12.0 to 50.0 | 4.75 to 7.00 | 3.0 | 35 | 6 | |

| 35 | 20.00 to 25.00 | 5.00 to 7.50 | 40 | ||||

| [ ! ]L+T ≤ P × 3.0 | |||||||

Alterations

| Part Number | — | P | — | W | — | L | — | (HC·RH) |

| JBAFPG18 JBFR10 | — — | P8.00 P6.0 | — | W4.5 | — — | L15.0 L10 | — — | HC RH |

| Alterations | Code | Spec. |

Set Screw Groove Depth | HC | Changes the depth of set screw groove depth from 0.5 mm to 1.0 mm. Ordering Code HC [ ! ] Applicable to Retaining Straight only [ ! ] Applicable to D dimension 18 or more |

I.D. Radius R | RH | Changes the inner diameter radius R from shoulder side to D dimension end face. Size of R will be the same as R on shoulder side. Ordering Code RH [ ! ] Applicable to Compact Flange, Economy Type only [ ! ] (D−P)/2−R ≥ 1.7 |

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

- ( - ) | 14 working days |

More Information

Basic information

[Features] Bushing that prevents disassembly by a set screw. [Modification aid] Changing the depth of the threaded part of the set screw and changing the inner diameter R.

Outline and specifications

App. Example

Notched

General Information - Flanged Drill Bushes

Selection between drill bushings / positioning bushings / centering bushings

- Material: steel, stainless steel, brass, ceramics

- Coatings: untreated, nickel-plated, burnished

- Hardness: 50HRC to 62HRC

- Fastening: with notch, mounting bracket, with dowel pin, pressed-in

- Inside diameter shape: round, oval

- ISO tolerances: g6, h6, m6, n6, p6, 0/-0.2, 0/-0.01

- Inside diameter: 2 mm to 35 mm

- Outside diameter: 5 mm to 48 mm

- Length: 3 mm to 60 mm

Here to the drill bushings Overview as PDF

Description / Basics

A drill bushing is intended for precise centering, positioning and guidance of drills. They can be used in drilling rigs or for multi-spindle drilling heads as well as a drilling jig. Therefore, it is possible to create an accurate and recurring bore at the same position in one component. In addition, through the guide the drill bushing protects the drill from breakage. The most common bushings are the collar drill bushing according to DIN 172 and the cylindrical drill bushing according to DIN 179.

Drill bushings and collar drill bushings are available in a variety of fastening types. They can be pressed in or secured with a semi-circular notch in the collar of the plug-in fulcrum pins. Since it is not pressed, this has the advantage of quick interchangeability. MISUMI also offers the special form of a flanged bushing with mounting flange.

Collar bushings with oval bores are also available at MISUMI. These are provided with a semi-circular notch in the collar, which, in combination with a dowel pin, serves to align the collar drill bushing.

Drill bushings are often used as positioning bushings or centering bushings.

Due to the rounded insertion of the drill bushing, it can serve as a joining opening for centering pins or height adjusting pins.

Application Examples - Flanged Drill Bushes

Example for using a centering bolt/centering bushing with collar

(1) Locating pin, (2) Bushings for fixtures

Example for using a centering bolt/centering bushing

(1) Locating pin , (2) Bushings for fixtures, (3) Mounting plate

Industrial Applications