- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 3:00 21/4/2024 to 0:00 (CET) 22/4/2024. We apologize for the inconvenience.

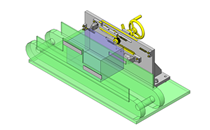

Spur gears / tooth width / hub dimension configurable / contact angle 20 degrees

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Type | Material | Surface Treatment | Accessory | ||

| Straight Bore | Straight Bore + Tap | Keyway + Tap | |||

| GEFHB | GEFB | GEFKB | EN 1.1191 Equiv. | - | Set Screw (EN 1.7220 Equiv., Black Oxide) |

| GEFHBB | GEFBB | GEFKBB | Black Oxide | ||

| GEFHBG | GEFBG | GEFKBG | Electroless Nickel Plating | ||

| GEFHBS | GEFBS | GEFKBS | EN 1.4301 Equiv. | - | Set Screw (EN 1.4301 Equiv.) |

Specifications

| Part Number | - | Number of Teeth | - | B | - | P | - | W | - | H |

| GEFHB1.0 GEFKBG2.0 | - - | 30 32 | - - | 8 15 | - - | 15 20N | - - | W10 W0 | - | H26 |

| Part Number | Number of Teeth | B 1mm Increment | Shaft Bore Dia. PH7 (1mm Increment) | Hub 1mm Increment | d Reference Dia. | D Tip Dia. | G Root Dia. | Unit Price | ||||||||||||||

| Type | Module | Straight Bore Straight Bore + Tap | Keyway + Tap | W | H | Straight Bore | Straight Bore + Tap | Keyway + Tap | ||||||||||||||

| GEFHB | GEFHBB | GEFHBG | GEFHBS | GEFB | GEFBB | GEFBG | GEFBS | GEFKB | GEFKBB | GEFKBG | GEFKBS | |||||||||||

| Straight Bore GEFHB GEFHBB GEFHBG GEFHBS Straight Bore + Tap GEFB GEFBB GEFBG GEFBS Keyway + Tap GEFKB GEFKBB GEFKBG GEFKBS | 0.5 | 20 | 2~5 | 3 4 | - | 0~10 | P+2≤H≤G-2 (Straight Bore) P+4≤H≤G-2 (Straight Bore + Tap) | 10 | 11 | 8.75 | - | - | - | - | ||||||||

| 24 | 3~6 | 12 | 13 | 10.75 | - | - | - | - | ||||||||||||||

| 25 | 12.5 | 13.5 | 11.25 | - | - | - | - | |||||||||||||||

| 26 | 13 | 14 | 11.75 | - | - | - | - | |||||||||||||||

| 30 | 15 | 16 | 13.75 | - | - | - | - | |||||||||||||||

| 32 | 16 | 17 | 14.75 | - | - | - | - | |||||||||||||||

| 36 | 3~12 | 18 | 19 | 16.75 | - | - | - | - | ||||||||||||||

| 40 | 20 | 21 | 18.75 | - | - | - | - | |||||||||||||||

| 48 | 24 | 25 | 22.75 | - | - | - | - | |||||||||||||||

| 50 | 25 | 26 | 23.75 | - | - | - | - | |||||||||||||||

| 60 | 5~25 | 30 | 31 | 28.75 | - | - | - | - | - | - | ||||||||||||

| 70 | 35 | 36 | 33.75 | - | - | - | - | - | - | |||||||||||||

| 80 | 40 | 41 | 38.75 | - | - | - | - | - | - | |||||||||||||

| 100 | 50 | 51 | 48.75 | - | - | - | - | - | - | |||||||||||||

| 0.8 | 15 | 3~10 | 5 6 6.35 | - | 0~10 | P+2≤H≤G-2 (Straight Bore) P+4≤H≤G-2 (Straight Bore + Tap) | 12 | 13.6 | 10 | - | - | - | - | |||||||||

| 16 | 12.8 | 14.4 | 10.8 | - | - | - | - | |||||||||||||||

| 18 | 14.4 | 16 | 12.4 | - | - | - | - | |||||||||||||||

| 20 | 16 | 17.6 | 14 | - | - | - | - | |||||||||||||||

| 24 | 5~8 | 19.2 | 20.8 | 17.2 | - | - | - | - | ||||||||||||||

| 25 | 20 | 21.6 | 18 | - | - | - | - | |||||||||||||||

| 28 | 22.4 | 24 | 20.4 | - | - | - | - | |||||||||||||||

| 30 | 24 | 25.6 | 22 | - | - | - | - | |||||||||||||||

| 32 | 25.6 | 27.2 | 23.6 | - | - | - | - | |||||||||||||||

| 36 | 6~8 6.35 | 28.8 | 30.4 | 26.8 | - | - | - | - | ||||||||||||||

| 40 | 32 | 33.6 | 30 | - | - | - | - | |||||||||||||||

| 45 | 36 | 37.6 | 34 | - | - | - | - | |||||||||||||||

| 48 | 38.4 | 40 | 36.4 | - | - | - | - | |||||||||||||||

| 50 | 40 | 41.6 | 38 | - | - | - | - | |||||||||||||||

| 1.0 | 20 | 5~15 | 6~12 | 8N | 0~15 | P+4≤H≤G-3 (Straight Bore, Straight Bore + Tap) P+6≤H≤G-3 (Keyway + Tap) | 20 | 22 | 17.5 | |||||||||||||

| 21 | 8N~10N | 21 | 23 | 18.5 | ||||||||||||||||||

| 22 | 22 | 24 | 19.5 | |||||||||||||||||||

| 23 | 23 | 25 | 20.5 | |||||||||||||||||||

| 24 | 24 | 26 | 21.5 | |||||||||||||||||||

| 25 | 25 | 27 | 22.5 | |||||||||||||||||||

| 26 | 6~18 | 8N~12N | 26 | 28 | 23.5 | |||||||||||||||||

| 28 | 28 | 30 | 25.5 | |||||||||||||||||||

| 30 | P+10≤H≤G-3 (Straight Bore, Straight Bore + Tap) P+13≤H≤G-3 (Keyway + Tap) | 30 | 32 | 27.5 | ||||||||||||||||||

| 32 | 32 | 34 | 29.5 | |||||||||||||||||||

| 35 | 8~20 | 35 | 37 | 32.5 | ||||||||||||||||||

| 36 | 8N~20N | 36 | 38 | 33.5 | ||||||||||||||||||

| 40 | 40 | 42 | 37.5 | |||||||||||||||||||

| 48 | 8~35 | 48 | 50 | 45.5 | ||||||||||||||||||

| 50 | 10N~30N | 50 | 52 | 47.5 | ||||||||||||||||||

| 60 | 60 | 62 | 57.5 | |||||||||||||||||||

| 70 | 10~40 | 12N~35N | 70 | 72 | 67.5 | |||||||||||||||||

| 80 | 80 | 82 | 77.5 | |||||||||||||||||||

| 100 | 15~40 | 15N~35N | 100 | 102 | 97.5 | |||||||||||||||||

| 120 | 120 | 122 | 117.5 | |||||||||||||||||||

| 1.5 | 16 | 10~20 | 6~12 | 8N~12N | 0~20 | P+6≤H≤G-4 | 24 | 27 | 20.25 | |||||||||||||

| 18 | 27 | 30 | 23.25 | |||||||||||||||||||

| 20 | 30 | 33 | 26.25 | |||||||||||||||||||

| 24 | 6~18 | 8N~15N | 36 | 39 | 32.25 | |||||||||||||||||

| 25 | P+13≤H≤G-4 (Straight Bore, Straight Bore + Tap) P+15≤H≤G-4 (Keyway + Tap) | 37.5 | 40.5 | 33.75 | ||||||||||||||||||

| 26 | 39 | 42 | 35.25 | |||||||||||||||||||

| 28 | 42 | 45 | 38.25 | |||||||||||||||||||

| 30 | 6~25 | 8N~25N | 45 | 48 | 41.25 | |||||||||||||||||

| 35 | 52.5 | 55.5 | 48.75 | |||||||||||||||||||

| 36 | 54 | 57 | 50.25 | |||||||||||||||||||

| 40 | 8~40 | 8N~30N | 60 | 63 | 56.25 | |||||||||||||||||

| 48 | 72 | 75 | 68.25 | |||||||||||||||||||

| 50 | 75 | 78 | 71.25 | |||||||||||||||||||

| 60 | 12~40 | 12N~35N | P+15≤H≤G-4 (Straight Bore, Straight Bore + Tap) P+20≤H≤G-4 (Keyway + Tap) | 90 | 93 | 86.25 | ||||||||||||||||

| 70 | 105 | 108 | 101.25 | |||||||||||||||||||

| 80 | 120 | 123 | 116.25 | - | - | - | ||||||||||||||||

■Module 2.0, 2.5, 3.0

| Part Number | Number of Teeth | B 1mm Increment | Shaft Bore Dia. PH7 (1mm Increment) | Hub 1mm Increment | d Reference Dia. | D Tip Dia. | G Root Dia. | Unit Price | ||||||||||||||

| Type | Module | Straight Bore Straight Bore + Tap | Keyway + Tap | W | H | Straight Bore | Straight Bore + Tap | Keyway + Tap | ||||||||||||||

| GEFHB | GEFHBB | GEFHBG | GEFHBS | GEFB | GEFBB | GEFBG | GEFBS | GEFKB | GEFKBB | GEFKBG | GEFKBS | |||||||||||

| Straight Bore GEFHB GEFHBB GEFHBG GEFHBS Straight Bore + Tap GEFB GEFBB GEFBG GEFBS Keyway + Tap GEFKB GEFKBB GEFKBG GEFKBS | 2.0 | 15 | 15~25 | 8~15 | 8N~12N | 0~25 | P+10≤H≤G-5 (Straight Bore, Straight Bore + Tap) P+12≤H≤G-5 (Keyway + Tap) | 30 | 34 | 25 | ||||||||||||

| 16 | 32 | 36 | 27 | |||||||||||||||||||

| 18 | 36 | 40 | 31 | |||||||||||||||||||

| 20 | 40 | 44 | 35 | |||||||||||||||||||

| 24 | 8~20 | 8N~17N | 48 | 52 | 43 | |||||||||||||||||

| 25 | 50 | 54 | 45 | |||||||||||||||||||

| 26 | 52 | 56 | 47 | |||||||||||||||||||

| 30 | 8~25 | 8N~20N | 60 | 64 | 55 | |||||||||||||||||

| 32 | 64 | 68 | 59 | |||||||||||||||||||

| 36 | 10~30 | 10N~25N | P+12≤H≤G-5 (Straight Bore, Straight Bore + Tap) P+14≤H≤G-5 (Keyway + Tap) | 72 | 76 | 67 | ||||||||||||||||

| 40 | 80 | 84 | 75 | |||||||||||||||||||

| 48 | 10~35 | 10N~30N | 96 | 100 | 91 | |||||||||||||||||

| 50 | 100 | 104 | 95 | |||||||||||||||||||

| 52 | 12~40 | 12N~35N | 104 | 108 | 99 | |||||||||||||||||

| 60 | 120 | 124 | 115 | |||||||||||||||||||

| 2.5 | 18 | 20~30 | 8~15 | 8N~12N | 0~30 | P+10≤H≤G-6 (Straight Bore, Straight Bore + Tap) P+12≤H≤G-6 (Keyway + Tap) | 45 | 50 | 38.75 | |||||||||||||

| 20 | 50 | 55 | 43.75 | |||||||||||||||||||

| 25 | 8~20 | 8N~17N | 62.5 | 67.5 | 56.25 | |||||||||||||||||

| 28 | 8~25 | 8N~20N | 70 | 75 | 63.75 | |||||||||||||||||

| 36 | 8~30 | 8N~25N | P+12≤H≤G-6 (Straight Bore, Straight Bore + Tap) P+14≤H≤G-6 (Keyway + Tap) | 90 | 95 | 83.75 | ||||||||||||||||

| 40 | 100 | 105 | 93.75 | |||||||||||||||||||

| 50 | 12~40 | 12N~35N | 125 | 130 | 118.75 | |||||||||||||||||

| 3.0 | 12 | 25~35 | 8~15 | 8N~12N | 0~35 | P+10≤H≤G-7 (Straight Bore, Straight Bore + Tap) P+12≤H≤G-7 (Keyway + Tap) | 36 | 42 | 28.5 | |||||||||||||

| 15 | 45 | 51 | 37.5 | |||||||||||||||||||

| 18 | 8~20 | 8N~20N | 54 | 60 | 46.5 | |||||||||||||||||

| 20 | 8~25 | 8N~25N | 60 | 66 | 52.5 | |||||||||||||||||

| 30 | 10~30 | 10N~30N | P+12≤H≤G-7 (Straight Bore, Straight Bore + Tap) P+14≤H≤G-7 (Keyway + Tap) | 90 | 96 | 82.5 | ||||||||||||||||

| 36 | 12~40 | 12N~35N | 108 | 114 | 100.5 | |||||||||||||||||

| 40 | 120 | 126 | 112.5 | |||||||||||||||||||

When the tooth width is smaller, the transmitting torque is smaller. Shaft bore diameter 6.35 is available for Straight Bore and Straight Bore + Tap.

Specify 10K as the P dimension if keyway width of 4.0mm (height 1.8mm) for Keyway + Tap with shaft bore diameter of 10 is desired >> P.1498

When requesting Shape A (no hub), specify W=0.

When W=0, specification for H is not required.

For WDH alterations, the H range requirements considered as Q and R = P must satisfy the condition of "Q+○ ≤ H ≤ G - ○, R+ ○ ≤ H ≤ G - ○." (○: Refer to the value in the specification table)

For DHL/DHR alterations, the H range requirements considered as Z = P must satisfy the condition of "Z + ○ ≤ H ≤ G - ○." (○: Refer to the value in the specification table)

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| GEFB0.5-20-[2-5/1]-[3-4/1]-W[0-10/1] |

| GEFB0.5-24-[2-5/1]-[3-6/1]-W[0-10/1] |

| GEFB0.5-25-[2-5/1]-[3-6/1]-W[0-10/1] |

| GEFB0.5-26-[2-5/1]-[3-6/1]-W[0-10/1] |

| GEFB0.5-30-[2-5/1]-[3-6/1]-W[0-10/1] |

| GEFB0.5-32-[2-5/1]-[3-6/1]-W[0-10/1] |

| GEFB0.5-36-[2-5/1]-[3-12/1]-W[0-10/1] |

| GEFB0.5-40-[2-5/1]-[3-12/1]-W[0-10/1] |

| GEFB0.5-48-[2-5/1]-[3-12/1]-W[0-10/1] |

| GEFB0.5-50-[2-5/1]-[3-12/1]-W[0-10/1] |

| GEFB0.5-60-[2-5/1]-[5-25/1]-W[0-10/1] |

| GEFB0.5-70-[2-5/1]-[5-25/1]-W[0-10/1] |

| GEFB0.5-80-[2-5/1]-[5-25/1]-W[0-10/1] |

| GEFB0.5-100-[2-5/1]-[5-25/1]-W[0-10/1] |

| GEFB0.8-15-[3-10/1]-[5,6,6.35]-W[0-10/1] |

| GEFB0.8-16-[3-10/1]-[5,6,6.35]-W[0-10/1] |

| GEFB0.8-18-[3-10/1]-[5,6,6.35]-W[0-10/1] |

| GEFB0.8-20-[3-10/1]-[4-6/1]-W[0-10/1] |

| GEFB0.8-20-[3-10/1]-[5,6,6.35]-W[0-10/1] |

| GEFB0.8-24-[3-10/1]-[5-8/1]-W[0-10/1] |

| GEFB0.8-25-[3-10/1]-[5-8/1]-W[0-10/1] |

| GEFB0.8-28-[3-10/1]-[5-8/1]-W[0-10/1] |

| GEFB0.8-30-[3-10/1]-[5-8/1]-W[0-10/1] |

| GEFB0.8-32-[3-10/1]-[5-8/1]-W[0-10/1] |

| GEFB0.8-36-[3-10/1]-[6.35,8]-W[0-10/1] |

| GEFB0.8-40-[3-10/1]-[6-8/1]-W[0-10/1] |

| GEFB0.8-45-[3-10/1]-[6-8/1]-W[0-10/1] |

| GEFB0.8-48-[3-10/1]-[6.35,8]-W[0-10/1] |

| GEFB0.8-50-[3-10/1]-[6.35,8]-W[0-10/1] |

| GEFB1.0-20-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-20-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-21-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-21-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-22-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-22-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-23-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-23-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-24-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-24-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-25-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-25-[5-15/1]-[6-12/1]-W[0-15/1] |

| GEFB1.0-26-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-26-[5-15/1]-[6-18/1]-W[0-15/1] |

| GEFB1.0-28-[5-15/1]-[6-18/1]-W[0-15/1] |

| GEFB1.0-30-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-30-[5-15/1]-[6-18/1]-W[0-15/1] |

| GEFB1.0-32-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-32-[5-15/1]-[6-18/1]-W[0-15/1] |

| GEFB1.0-35-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-35-[5-15/1]-[8-20/1]-W[0-15/1] |

| GEFB1.0-36-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-36-[5-15/1]-[8-20/1]-W[0-15/1] |

| GEFB1.0-40-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-40-[5-15/1]-[8-20/1]-W[0-15/1] |

| GEFB1.0-48-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-48-[5-15/1]-[8-35/1]-W[0-15/1] |

| GEFB1.0-50-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-50-[5-15/1]-[8-35/1]-W[0-15/1] |

| GEFB1.0-60-[5-15/1]-6.35-W[0-15/1] |

| GEFB1.0-60-[5-15/1]-[8-35/1]-W[0-15/1] |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Number of Teeth (Teeth) | Material | Surface Treatment | Shaft Bore Dia. (Ø) | Tooth Width B (mm) | Hole Shape | Hub Width [W] (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 8 Days | 10 | 20 | General Steel Material | Not Provided | 3 ~ 4 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 24 | General Steel Material | Not Provided | 3 ~ 6 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 25 | General Steel Material | Not Provided | 3 ~ 6 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 26 | General Steel Material | Not Provided | 3 ~ 6 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 30 | General Steel Material | Not Provided | 3 ~ 6 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 32 | General Steel Material | Not Provided | 3 ~ 6 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 36 | General Steel Material | Not Provided | 3 ~ 12 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 40 | General Steel Material | Not Provided | 3 ~ 12 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 48 | General Steel Material | Not Provided | 3 ~ 12 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 50 | General Steel Material | Not Provided | 3 ~ 12 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 60 | General Steel Material | Not Provided | 5 ~ 25 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 70 | General Steel Material | Not Provided | 5 ~ 25 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 80 | General Steel Material | Not Provided | 5 ~ 25 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 100 | General Steel Material | Not Provided | 5 ~ 25 | 2 ~ 5 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 15 | General Steel Material | Not Provided | 5 ~ 6.35 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 16 | General Steel Material | Not Provided | 5 ~ 6.35 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 18 | General Steel Material | Not Provided | 5 ~ 6.35 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 20 | General Steel Material | Not Provided | 4 ~ 6 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 20 | General Steel Material | Not Provided | 5 ~ 6.35 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 24 | General Steel Material | Not Provided | 5 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 25 | General Steel Material | Not Provided | 5 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 28 | General Steel Material | Not Provided | 5 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 30 | General Steel Material | Not Provided | 5 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 32 | General Steel Material | Not Provided | 5 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 36 | General Steel Material | Not Provided | 6.35 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 40 | General Steel Material | Not Provided | 6 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 45 | General Steel Material | Not Provided | 6 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 48 | General Steel Material | Not Provided | 6.35 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 50 | General Steel Material | Not Provided | 6.35 ~ 8 | 3 ~ 10 | Round Hole + Tap | 0 ~ 10 | ||

- | 1 | 8 Days | 10 | 20 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 20 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 21 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 21 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 22 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 22 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 23 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 23 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 24 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 24 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 25 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 25 | General Steel Material | Not Provided | 6 ~ 12 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 26 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 26 | General Steel Material | Not Provided | 6 ~ 18 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 28 | General Steel Material | Not Provided | 6 ~ 18 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 30 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 30 | General Steel Material | Not Provided | 6 ~ 18 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 32 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 32 | General Steel Material | Not Provided | 6 ~ 18 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 35 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 35 | General Steel Material | Not Provided | 8 ~ 20 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 36 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 36 | General Steel Material | Not Provided | 8 ~ 20 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 40 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 40 | General Steel Material | Not Provided | 8 ~ 20 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 48 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 48 | General Steel Material | Not Provided | 8 ~ 35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 50 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 50 | General Steel Material | Not Provided | 8 ~ 35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 60 | General Steel Material | Not Provided | 6.35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 | ||

- | 1 | 8 Days | 10 | 60 | General Steel Material | Not Provided | 8 ~ 35 | 5 ~ 15 | Round Hole + Tap | 0 ~ 15 |

Loading...

Basic information

| Shape | Shape A / Shape B | Heat Treatment | Not Provided | Ground Tooth | Not Provided |

|---|---|---|---|---|---|

| Backlash | Provided | Bearing | Not Provided | Shaft Bore Tolerance | H7 |

| Precision(Old JIS) | JIS B 1702 (Class 4) |

Configure

Basic Attributes

-

Number of Teeth(Teeth)

-

Material

- General Steel Material

- Stainless Steel

-

Surface Treatment

-

Shaft Bore Dia.(Ø)

[3-40/1Ø Unit(s)]

-

Tooth Width B(mm)

-

Hole Shape

- Keyway Hole + Tap

- Round Hole

- Round Hole + Tap

-

Hub Width [W](mm)

-

Type

- GEFB

- GEFBB

- GEFBG

- GEFBS

- GEFHB

- GEFHBB

- GEFHBG

- GEFHBS

- GEFKB

- GEFKBB

- GEFKBG

- GEFKBS

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 8 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

MISUMI Unit еxample related to this product

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry