- Plate Thickness T(mm)

- 12.7

- 19.1

- 25.4

- Width B(mm)[20-1240/1mm units]

- Length A(mm)[20-1240/1mm units]

- Tolerance Selection

- Counterbore Hole (Screw Nominal Dia.) [Z]

- 4

- 5

- 6

- 8

- F(mm)[9-1231/0.5mm units]

- G(mm)[5-995/0.5mm units]

- Through Hole (Screw Nominal Dia.) [N]

- 3

- 4

- 5

- 6

- 8

- 10

- CAD

- 2D

- Est. shipping days

- All

- Within 7 working days

- Within 9 working days

Heat Insulating Plates / Very High Temperature Insulating Grade

Part number:

possible part numbers found.Outline drawing and specifications table

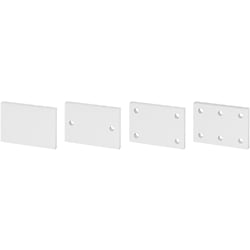

Dimensional Drawing

| Standard | With Holes | |||||

| 2 Holes 2H | 4 Holes 4H | 6 Holes 6H | ||||

|  |  |  |

| Hole Machining Detail | |||||||||||||||||||||||||||||||||||||||||||||

| N (Through Hole) | Z (Counterbore Hole) | ||||||||||||||||||||||||||||||||||||||||||||

|  | ||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||

Specification Table

| Type | Tolerance Selection | Component | Color | Operating Ambient Temperature |

| HRMB | Not Specified | Silicic Acid Calcium | White | Room Temp. to 1,000°C |

| P |

| Type | Tolerance Selection | A | B | Dim. Tolerance of A and B |

| HRMB | Not Specified | 20 to 800 | 20 to 600 | 0 +1 |

| 801 or more | 601 or more | 0 +2 | ||

| HRMBP | P | 20 to 1240 | 20 to 950 | ±0.3 |

| Part Number | 1 mm Increments | Selection | ||

| Type | Tolerance Selection | A | B | T |

| HRMB | Not Specified | 20 to 1240 | 20 to 1240 | 12.7 19.1 25.4 |

| P | 20 to 1240 | 20 to 950 | ||

| Part Number | 1 mm Increments | Selection T | 0.5 mm Increments | Bolt Hole Nominal Dia. Selection | ||||||||

| Type | Tolerance Selection | Number of Holes | A | B | F | G | Through Hole | Counterbore Hole | ||||

| N | Z | |||||||||||

| HRMB | Not Specified | 2H 4H 6H | 20 to 1240 | 20 to 1000 | 12.7 | 9 to 1231 (2H, 4H Type) 9 to 615 (6H Type) | 5 to 995 (2H) 9 to 991 (Other than 2H) | 3 4 5 6 8 10 | 4 | 5 | 6 | |

| 19.1 | 4 | 5 | 6 | 8 | ||||||||

| 25.4 | 4 | 5 | 6 | 8 | ||||||||

| P | 20 to 1240 | 20 to 950 | 12.7 | 9 to 1231 (2H, 4H Type) 9 to 615 (6H Type) | 5 to 945 (2H) 9 to 941 (Other than 2H) | 4 | 5 | 6 | ||||

| 19.1 | 4 | 5 | 6 | 8 | ||||||||

| 25.4 | 4 | 5 | 6 | 8 | ||||||||

[!] Dimension G Specification Range - 2H type selection: d (d1)/2 + 2.5 ≤ G ≤ B - d (d1)/2 - 2.5; 4H/6H type selection: d (d1) + 5 ≤ G ≤ B - d (d1) - 5 is required.

(d for through holes, d1 for counterbore holes.)

[ ! ] For Hole type, select N (through hole) or Z (Counterbore hole).

| Part Number | — | A | — | B | — | T |

| HRMB HRMBP | — — | 300 200 | — — | 222 100 | — — | 12.7 19.1 |

| Part Number | — | A | — | B | — | T | — | F | — | G | — | Bolt Nominal Dia. |

| HRMB2H HRMBP4H | — — | 200 200 | — — | 170 150 | — — | 12.7 12.7 | — — | F100 F150 | — — | G70 G120 | — — | N8 Z5 |

Alterations

| Part Number | — | A | — | B | — | T | — | F | — | G | — | Bolt Nominal Dia. | — | (XC·YC) | |

| HRMBP4H | — | 100 | — | 100 | — | 19.1 | — | F40 | — | G50 | — | N6 | — | XC30−YC20 | ||

| Alterations | Hole Position from Left | Hole Position from Bottom |

|  | |

| Code | XC | YC |

| Spec | XC = 1 mm Increments [ ! ]5 ≤ XC ≤ 786 [!] (2H, 4H Type) d (d1)/2 + 2.5 ≤ XC ≤ A - F - d (d1)/2 - 2.5 [!] (6H Type) d (d1)/2 + 2.5 ≤ XC ≤ A - 2F - d (d1)/2 - 2.5 | YC = 1 mm Increments [ ! ]5 ≤ YC ≤ 586 [ ! ] d (d1)/2 + 2.5 ≤ YC ≤ B - G - d (d1)/2 - 2.5 [NG] Not applicable for 2H Type |

Related information for heat insulating plate

Notes on Usage of Insulating Plate and Thermal Plate

(1) Be sure to use a washer with a bolt. Please note that over-tightening may result in cracking.

Please pay special attention to the Thermal Plate (HIPCA) because it is soft. (Fig. A)

(2) Do not use in places where there may be splashes of water, chemicals, etc. Heat Insulating Plate that contain moisture can crack and cause significant performance loss due to temperature rise. Free Cutting Grade (HIPMA), in particular, easily absorb moisture, so please dry them thoroughly before use.

(3) Avoid using the laminated products with force applied in the direction of the layers (in the direction of cleavage).

(4) When using the High Temperature Insulating Grade (HIPHA) and Thermal Plate (HIPCA) at 300°C or higher, initial smoke and a slight odor (only a slight odor for heat-insulating plate (IPCA)) may occur, but they are not particularly harmful, so please take the same measures as for normal smoke emissions, such as ventilation and keeping your face away from the product.

(5) The thermal plate has a cavity inside the product to create a high heat-insulating effect. They may have lines on the surface, but the lines do not affect the property and heat insulating effect.

Notes on Machining of Insulating Plate and Thermal Plate

(1) When machining, vacuum dust into a dust collector so that it may not scatter. (Fig. B- (1))

Be sure to firmly fix a Insulating Plate on the bench because it is soft.

The dust does not contain the designated chemicals such as asbestos, but safety measures for usual works in dust, such as masks and goggles, are required. It may affect the skin such as itching, because it contains glass fiber.

Wear gloves when handling the plates.

In addition, when dusts adhere to the sliding parts of machine tools, there may be degradation in accuracy due to abrasion.

(2) Drilling of the insulating plate may cause cracks. Attention should be taken to hole pitches, hole diameters, machining conditions, etc. (Fig. B- (2))

(3) They are laminated products, and not suitable for tapping and three-dimensional machining. Especially, drilling or cutting in the direction of material lamination should be avoided as it may cause cracking. (Fig. C)

Machining Conditions

| Circular Cut | Milling | Drilling | |

| Tool | Carbide (K−10) | Carbide (K−10) | Carbide (K−10) |

| Cutting Speed V (m/min) | Large to Small Blades 45 to 200 | Large to Small Blades 100 to 300 | Large to Small Blades 120 to 350 |

| Rotational Speed (rpm) | Large to Small Blades 50 to 1000 | Large to Small Blades 300 to 1000 | φ2 Through 1000 to 1500 φ5 Through 500 to 1000 |

| Cutting Depth (mm) | 0.3 to 0.5 | 0.5 to 2.0 | − |

| Feed (mm/rotation) | 0.1 to 0.2 | 0.1 to 0.2 | 0.1 to 0.5 |

[ ! ] Please prepare plates, etc. as pads in advance as it is very easy to break when pulling out.

[ ! ] Please avoid machining in the direction shown in the above figure as much as possible.

Information on material properties of heat insulating plate

| Item | Unit | High Heat Resistance | ||

| HRMB | ||||

| Component | Main Base Material | ー | Silicic Acid Calcium | |

| Main Material | ー | |||

| Electrical Characteristics | Dielectric Breakdown in Crosswise | kV/mm | ー | |

| Volume Resistivity | 4h/150℃ | Ω-cm | ー | |

| 100h/25℃/90%RH | Ω-cm | ー | ||

| Surface Resistance | Ω | ー | ||

| Insulation Resistance | Ordinary Condition | Ω | ー | |

| After Boiling | Ω | ー | ||

| Mechanical Property | Bending Strength | Mpa | 8.8 | |

| Compression Strength | Vertical | Mpa | 4.4 | |

| Horizontal to Lamination | Mpa | ー | ||

| Izod Impact Strength | ー | ー | ||

| Cleavage Strength | kN | ー | ||

| Thermal Characteristics | Recommended Operating Temperature (*1) | ℃ | Room Temp. to 1000 | |

| Reference - Destruction Temperature (*2) | ℃ | ー | ||

| Expansion Coefficient | ℃−1 | ー | ||

| Thermal Conductivity | W/m・K | 0.2 | ||

| cal/cm・sec・℃ | 0.48×10−3 | |||

| Specific Heat | J/g・K | 0.9 | ||

| Others | Arc Resistance | sec | ー | |

| Water Absorption Ratio | % | ー | ||

| Specific Gravity | ー | 0.84 | ||

| Color | ー | White | ||

[ ! ] The values are representative values and not a guarantee.

[ ! ] Thermal conductivity measured by steady-state method

(Note 1) "Recommended Operating Temperature" is the temperature under which even a long-term use does not reduce the quality rapidly. Refer to

the "Heat Insulating Plates Characteristics Graph" below

(Note 2) "Destructive Temperature" is a temperature where carbonization, collapse, and meltdown will begin.

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 7 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 7 working days |