Configure

- Single Angle (θ)(Degree)

- 1

- Outer Diameter (D)(φ)

- 1

- Flute Length (ℓ)(mm)

- 10

- Shank Diameter (d)(mm)

- 4

- Overall Length (L)(mm)

- 45

- Type

- Est. shipping days

- All

- Within 5 working days

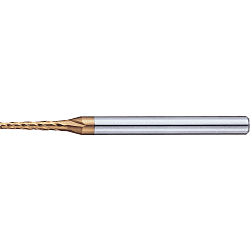

TSC series carbide tapered end mill, 4-flute / for deep ribbing (TSC-TEM4LB1-1-10)

Outline drawing

More Information

Basic information

[Features]

-Since the cutting edge has been processed into a sharp corner, it is also possible to machine corner edges

-The coating has high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating characteristics.

Specifications and price

Specifications

| Model Number | Large Tip Diameter D1 |

Overall Length L |

Shank Diameter d |

|||

| Outer Diameter D |

Single Angle θ |

Flute Length ℓ |

||||

| TSC-TEM4LB | 0.4 | 0.5° | 2 | 0.43 | 40 | 3 |

| 1° | 2 | 0.47 | 40 | 3 | ||

| 1.5° | 2 | 0.50 | 40 | 3 | ||

| 2° | 2 | 0.54 | 40 | 3 | ||

| 0.5° | 3 | 0.47 | 40 | 3 | ||

| 1° | 3 | 0.54 | 40 | 3 | ||

| 1.5° | 3 | 0.61 | 40 | 3 | ||

| 2° | 3 | 0.68 | 40 | 3 | ||

| 0.5 | 0.5° | 4 | 0.57 | 40 | 3 | |

| 1° | 4 | 0.64 | 40 | 3 | ||

| 1.5° | 4 | 0.71 | 40 | 3 | ||

| 2° | 4 | 0.78 | 40 | 3 | ||

| 0.6 | 0.5° | 4 | 0.67 | 40 | 3 | |

| 1° | 4 | 0.74 | 40 | 3 | ||

| 1.5° | 4 | 0.81 | 40 | 3 | ||

| 2° | 4 | 0.88 | 40 | 3 | ||

| 0.5° | 6 | 0.70 | 40 | 3 | ||

| 1° | 6 | 0.81 | 40 | 3 | ||

| 1.5° | 6 | 0.91 | 40 | 3 | ||

| 2° | 6 | 1.02 | 40 | 3 | ||

| 0.8 | 0.5° | 6 | 0.90 | 45 | 4 | |

| 1° | 6 | 1.01 | 45 | 4 | ||

| 1.5° | 6 | 1.11 | 45 | 4 | ||

| 2° | 6 | 1.22 | 45 | 4 | ||

| 0.5° | 8 | 0.94 | 45 | 4 | ||

| 1° | 8 | 1.08 | 45 | 4 | ||

| 1.5° | 8 | 1.22 | 45 | 4 | ||

| 2° | 8 | 1.36 | 45 | 4 |

| Model Number | Large Tip Diameter D1 |

Overall Length L |

Shank Diameter d |

|||

| Outer Diameter D |

Single Angle θ |

Flute Length ℓ |

||||

| TSC-TEM4LB | 1 | 0.5° | 6 | 1.10 | 45 | 4 |

| 1° | 6 | 1.21 | 45 | 4 | ||

| 1.5° | 6 | 1.31 | 45 | 4 | ||

| 2° | 6 | 1.42 | 45 | 4 | ||

| 0.5° | 8 | 1.14 | 45 | 4 | ||

| 1° | 8 | 1.28 | 45 | 4 | ||

| 1.5° | 8 | 1.42 | 45 | 4 | ||

| 2° | 8 | 1.56 | 45 | 4 | ||

| 0.5° | 10 | 1.17 | 45 | 4 | ||

| 1° | 10 | 1.35 | 45 | 4 | ||

| 1.5° | 10 | 1.52 | 45 | 4 | ||

| 2° | 10 | 1.70 | 45 | 4 | ||

| 1.2 | 0.5° | 8 | 1.34 | 45 | 4 | |

| 1° | 8 | 1.48 | 45 | 4 | ||

| 1.5° | 8 | 1.62 | 45 | 4 | ||

| 2° | 8 | 1.76 | 45 | 4 | ||

| 0.5° | 10 | 1.37 | 45 | 4 | ||

| 1° | 10 | 1.55 | 45 | 4 | ||

| 1.5° | 10 | 1.72 | 45 | 4 | ||

| 2° | 10 | 1.90 | 45 | 4 | ||

| 1.5 | 0.5° | 10 | 1.67 | 50 | 4 | |

| 1° | 10 | 1.85 | 50 | 4 | ||

| 1.5° | 10 | 2.02 | 50 | 4 | ||

| 2° | 10 | 2.20 | 50 | 4 | ||

| 0.5° | 12 | 1.71 | 50 | 4 | ||

| 1° | 12 | 1.92 | 50 | 4 | ||

| 1.5° | 12 | 2.13 | 50 | 4 | ||

| 2° | 12 | 2.34 | 50 | 4 | ||

| 2 | 0.5° | 12 | 2.21 | 50 | 4 | |

| 1° | 12 | 2.42 | 50 | 4 | ||

| 1.5° | 12 | 2.63 | 50 | 4 | ||

| 2° | 12 | 2.84 | 50 | 4 |

For Cutting Conditions, Refer to >>Click here.

Features and usage examples

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● The blade tip has a sharp edge allowing corner edges to also be machined.