Configure

- Shank Diameter d(mm)

- 4

- 6

- 8

- 10

- 12

- 16

- Overall Length L(mm)

- 50

- 60

- 80

- 90

- 100

- 120

- Processing Applications

- #2[3.01-16/0.01]

- #3[0.1-12/0.01]

- #4[0.1-5.9/0.01][3-43/0.5]

- #5[3-31/0.5][5-20/1]

- #6[5-20/1]

- F

- T

- Est. shipping days

- All

- Within 7 working days

- Within 8 working days

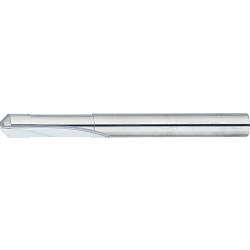

Carbide Straight Edge Corner C End Mill, 2-flute / Neck Relief Type

Part number:

possible part numbers found.Outline drawing

Part number list

Number of items

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 8 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 8 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

More Information

Basic information

[Features]

-Cornered chamfer shape with neck recess for efficient machining

-Specifying changes makes it possible to select a coating suitable for the material

-Can be reground. Please refer to the "Regrinding Service" page for application details, scope of services, prices, etc.

Specifications and price

Specification Table

| Model Number | Blade Diameter D 0.01mm Unit Specification | Corner C 0.01mm Unit Specification | Blade Length* ℓ 0.5 mm Unit Specification | Neck Length* ℓ1 1mm Unit Specification | Blade Shape (Selection) | *Specified range for under-neck length ℓ2 | Overall Length L | ||

| Shank diameter d | |||||||||

| BSZCEM | LS−BSZCEM | ||||||||

| SZCEM | LS−SZCEM | ||||||||

| BSZCEM LS−BSZCEM (Long Shank) SZCEM LS−SZCEM (Long Shank) | 4 | 3.01 to 4.00 | 0.10 ≤ C ≤ (D-0.2)/2 | 3.0 to 10.0 | 5 ≤ ℓ1 ≤ 20 | T (Indented Center) F (Flat) | ℓ+ℓ1 ≤ 15 | 50 | 80 |

| 6 | 3.01 to 6.00 | 3.0 to 19.0 | ℓ+ℓ1 ≤ 24 | 60 | 90 | ||||

| 8 | 4.01 to 8.00 | 3.0 to 23.0 | ℓ+ℓ1 ≤ 28 | 60 | 90 | ||||

| 10 | 6.01 to 10.00 | 3.0 to 30.0 | ℓ+ℓ1 ≤ 35 | 80 | 120 | ||||

| 12 | 8.01 to 12.00 | 3.0 to 31.0 | ℓ+ℓ1 ≤ 36 | 80 | 120 | ||||

| 16 | 10.01 to 16.00 | 3.0 to 43.0 | ℓ+ℓ1 ≤ 48 | 100 | − | ||||

*The combined size of the blade length (ℓ) and neck length (ℓ1) are within the above-mentioned under-neck length specification range.

Click here for the cutting conditions