- Rubber Group Material

- Nitrile Rubber

- Nitrile Rubber

- Silicone Rubber

- Silicone Rubber

- Silicone Rubber +Carbon

- Fluorosilicone rubber

- Usage Environment

- Color

- Black

- White

- White

- Salmon Pink

- Outer Diameter D(φ)

- 4

- 6

- 8

- 10

- 15

- 20

- 30

- 40

- Height L1(mm)

- 12.2

- 14

- 15

- Springs Power(N)

- Full length B(mm)

- 62.4

- 64.2

- 65.2

- Type

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 11 working days

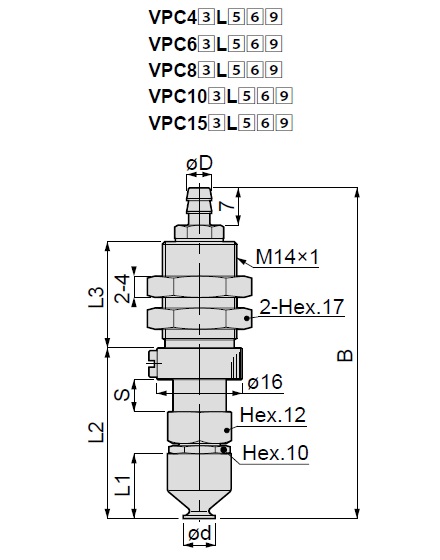

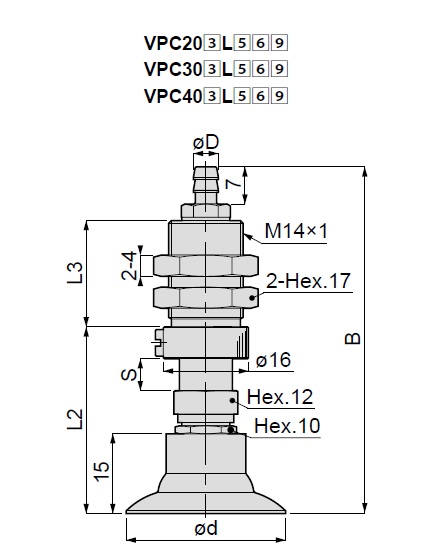

Vacuum Pad, Soft Type, VPC, Barb Fitting Type

Part number:

possible part numbers found.Product information

Dimensions

Standard table

| Model code | Pad O.D. ød | Tube I.D. øD | B | L1 | L2 | L3 | Stroke S | Spring force (N) | Connection config. code |

|---|---|---|---|---|---|---|---|---|---|

| VPC4-6L[5]-6B[9] | 4 | 4 | 62.4 | 12.2 | 32.3 | 20 | 6 | 4.0~7.1 | -M4 |

| VPC4-10L[5]-6B | 66.9 | 36.8 | 10 | 2.0~5.2 | |||||

| VPC4-15L[5]-6B | 76.9 | 41.8 | 25 | 15 | 2.0~5.9 | ||||

| VPC4-20L[5]-6B | 92.9 | 48.8 | 34 | 20 | 1.1~4.8 | ||||

| VPC6-6L[5]-6B[9] | 6 | 62.4 | 32.3 | 20 | 6 | 4.0~7.1 | |||

| VPC6-10L[5]-6B | 66.9 | 36.8 | 10 | 2.0~5.2 | |||||

| VPC6-15L[5]-6B | 76.9 | 41.8 | 25 | 15 | 2.0~5.9 | ||||

| VPC6-20L[5]-6B | 92.9 | 48.8 | 34 | 20 | 1.1~4.8 | ||||

| VPC8-6L[5]-6B[9] | 8 | 62.4 | 32.3 | 20 | 6 | 4.0~7.1 | |||

| VPC8-10L[5]-6B | 66.9 | 36.8 | 10 | 2.0~5.2 | |||||

| VPC8-15L[5]-6B | 76.9 | 41.8 | 25 | 15 | 2.0~5.9 | ||||

| VPC8-20L[5]-6B | 92.9 | 48.8 | 34 | 20 | 1.1~4.8 | ||||

| VPC10-6L[5]-6B[9] | 10 | 64.2 | 14 | 34.1 | 20 | 6 | 4.0~7.1 | ||

| VPC10-10L[5]-6B | 68.7 | 38.6 | 10 | 2.0~5.2 | |||||

| VPC10-15L[5]-6B | 78.7 | 43.6 | 25 | 15 | 2.0~5.9 | ||||

| VPC10-20L[5]-6B | 94.7 | 50.6 | 34 | 20 | 1.1~4.8 | ||||

| VPC15-6L[5]-6B[9] | 15 | 64.2 | 34.1 | 20 | 6 | 4.0~7.1 | |||

| VPC15-10L[5]-6B | 68.7 | 38.6 | 10 | 2.0~5.2 | |||||

| VPC15-15L[5]-6B | 78.7 | 43.6 | 25 | 15 | 2.0~5.9 | ||||

| VPC15-20L[5]-6B | 94.7 | 50.6 | 34 | 20 | 1.1~4.8 | ||||

| VPC20-6L[5]-6B[9] | 20 | 65.1 | 15 | 35 | 20 | 6 | 7.0~12.6 | -M6 | |

| VPC20-10L[5]-6B | 71.1 | 41 | 10 | 3.3~10.0 | |||||

| VPC20-15L[5]-6B | 81.1 | 46 | 25 | 15 | 3.3~10.4 | ||||

| VPC20-20L[5]-6B | 97.1 | 53 | 34 | 20 | 2.0~8.7 | ||||

| VPC30-6L[5]-6B[9] | 30 | 65.1 | 35 | 20 | 6 | 7.0~12.6 | |||

| VPC30-10L[5]-6B | 71.1 | 41 | 10 | 3.3~10.0 | |||||

| VPC30-15L[5]-6B | 81.1 | 46 | 25 | 15 | 3.3~10.4 | ||||

| VPC30-20L[5]-6B | 97.1 | 53 | 34 | 20 | 2.0~8.7 | ||||

| VPC40-6L[5]-6B[9] | 40 | 65.1 | 35 | 20 | 6 | 7.0~12.6 | |||

| VPC40-10L[5]-6B | 71.1 | 41 | 10 | 3.3~10.0 | |||||

| VPC40-15L[5]-6B | 81.1 | 46 | 25 | 15 | 3.3~10.4 | ||||

| VPC40-20L[5]-6B | 97.1 | 53 | 34 | 20 | 2.0~8.7 |

Units: mm

*[5]: Replaced with Pad rubber material code. Refer to the catalog for details.

*[9]: Replaced with "-S3" for -S3 spec. (Copper alloy free material for metal parts and FKM or HNBR for sealing parts).

*Pad material N and NE are not suitable for use under ozone environment.

*Tightening torque of a pad holder fixing bulkhead nut is 4.5~6 N·m.

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

31.26 € ( 37.20 € ) | 11 working days |

23.39 € ( 27.83 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

31.26 € ( 37.20 € ) | 11 working days |

23.39 € ( 27.83 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

32.01 € ( 38.09 € ) | 11 working days |

23.39 € ( 27.83 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

32.01 € ( 38.09 € ) | 11 working days |

23.39 € ( 27.83 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

34.05 € ( 40.52 € ) | 11 working days |

23.84 € ( 28.37 € ) | 11 working days |

25.24 € ( 30.04 € ) | 11 working days |

25.24 € ( 30.04 € ) | 11 working days |

34.98 € ( 41.63 € ) | 11 working days |

24.77 € ( 29.48 € ) | 11 working days |

26.17 € ( 31.14 € ) | 11 working days |

27.56 € ( 32.80 € ) | 11 working days |

35.90 € ( 42.72 € ) | 11 working days |

25.24 € ( 30.04 € ) | 11 working days |

26.63 € ( 31.69 € ) | 11 working days |

28.48 € ( 33.89 € ) | 11 working days |

37.75 € ( 44.92 € ) | 11 working days |

25.71 € ( 30.59 € ) | 11 working days |

28.03 € ( 33.36 € ) | 11 working days |

32.20 € ( 38.32 € ) | 11 working days |

More Information

Basic information

Optimal for removing molded parts and transporting easily scratched materials. *CAD data currently being revised for this series. This will be available as soon as modifications are complete.

[Features]

· The pad rubber is flexible enough to adhere plastic molded parts while leaving relatively few traces.

· A wide range of pad sizes, pad materials, and holder shapes are available.

· Downsizes holders (A and B types) for existing vacuum pads, saving space.

· The pad section can be changed without removing the holder from the equipment, as is conventional.

· Also compatible with the optional fall prevention valve and pad direct attachment type filter.

· Pad holder (VPHD and VPHE types) with vacuum inlet on both sides.