- R Size(mm)

- 1

- Flute Length (ℓ)(mm)

- 3

- Overall Length (L)(mm)

- 50

- Shank Diameter (d)(mm)

- 6

- Inventory Classification

- Type

- Est. shipping days

- All

- Within 5 working days

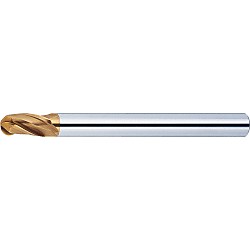

TSC series carbide ball end mill, 3-flute / short model (TSC-BEM3S1)

Outline drawing

More Information

Basic information

[Features]

-The 3-edge shape is resistant to chattering and enables high feed rate

-The surface of the workpiece is very well finished after machining.

-The coating has high oxidation resistance and high hardness and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.

Specifications and price

Specifications

| Model Number | Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Shank Diameter d |

Figure | |

| Tip R |

||||||

| TSC-BEM3S | 0.5 | 2 | 1 | 50 | 6 | 1 |

| 0.75 | 3 | 1.5 | 50 | 6 | 1 | |

| 1 | 3 | 2 | 50 | 6 | 1 | |

| 1.5 | 4 | 3 | 50 | 6 | 1 | |

| 2 | 6 | 4 | 50 | 6 | 1 | |

| 2.5 | 8 | 5 | 50 | 6 | 1 | |

| 3 | 10 | 6 | 60 | 6 | 2 | |

| 4 | 13 | 8 | 60 | 8 | 2 | |

| 5 | 15 | 10 | 80 | 10 | 2 | |

| 6 | 15 | 12 | 80 | 12 | 2 | |

| 8 | 20 | 16 | 150 | 16 | 2 | |

| 10 | 25 | 20 | 150 | 20 | 2 |

For Cutting Conditions, Refer to >>Click here.

Features and usage examples

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● Adopts a 3-flute shape to be strong against chatter and is capable of handling high feed rates.

● Delivers a finish with a very good working surface roughness after machining.

[ ! ]The following additional processing services are available for the products on this page.