Carbide Ball End Mills

Search by sub-category

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

Carbide Solid Spherical Cutter, 2-Flute

EIKOSHA

Copying Back / Curved Surface Deburring- Volume Discount

Configure nowStarting from∗ : 106.58 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Spherical Ball End GX-EQD-SF

OSG

Ball end mills having spherical cutting tips developed for shrink fitting.Configure nowStarting from∗ : 98.58 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

HM Coated 2-Flute, Long Neck Ball HSLB

UNION TOOL

[Features]

· Compared to conventional products, this model achieves higher machining efficiency, longer service life and higher quality machining of hard mold materials at 40 HRC or more.

· New HARDMAX coating adopted to maintain film hardness while improving oxidation resistance

· Provides stable processing for water-soluble/oil-based cutting oil, oil mist, and air blow

· The machining dimension has been improved by improving the wear resistance and setting the rake angle of the ball tip to negative

· The rake angle on the outer circumference side of the ball has been set to weak negative, securing sharpness, providing an excellent processed surface and preventing deflection- Volume Discount

- Stock

Configure nowStarting from∗ : 28.03 € Min. Shipping Days : Same day *Unit price with basic configuration

-

Carbide Solid Spherical Cutter, 4-Flute

EIKOSHA

Copying Back / Curved Surface Deburring- Volume Discount

Configure nowStarting from∗ : 128.66 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

CBN 2-Flute Spiral Ball-End Mill SBBEF-2

KYOWA SEIKO

Direct carving of high hardness materials and hardened steel.

It is possible to increase the depth of cut.

Machining applications (machining shape): Side face / curved face / engraving / R (radius) groove.Configure nowStarting from∗ : 152.07 € Min. Shipping Days : 7 Days *Unit price with basic configuration

-

Spherical Ball End FXS-EQD

OSG

Spherical cutting edge prevent chattering in the machining of standing wall. Machining undercut enabled.- Volume Discount

Configure nowStarting from∗ : 121.20 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

MRBH230 Long-Neck Ball, Hard (for High Hardness)

NS TOOL

The Infinity Coating Premium for high hardness and unique new shape provide excellent chipping resistance, and chattering is suppressed to improve the finished surface- Volume Discount

- Stock

Configure nowStarting from∗ : 26.97 € Min. Shipping Days : Same day *Unit price with basic configuration

-

Carbide Solid Spherical Cutter, 2-Flute Long Type

EIKOSHA

Copying Back / Curved Surface Deburring LongneckConfigure nowStarting from∗ : 145.23 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

SSPB220 CBN Super Spiral Ball End Mill

NS TOOL

[Features]

· Spiral ball shape used to improve sharpness of cutting edge.

· The cutting edge shape used improves the chipping resistance of the cutting edge.

· When the peripheral cutting edge makes contact with the cutting surface, chatter vibration occurs due to an increase in cutting resistance and this affects tool life and cutting surface quality. (This effect can be reduced by using a strong back taper shape.)

Torsion angle: 20°Configure nowStarting from∗ : 172.90 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 513.00 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TSC series carbide ball end mill, spherical, 2-flute / stub, long neck model

MISUMI

A lineup of 16 sizes centering on small diameter that employs a unique spherical cutting edge- Volume Discount

- TS

- General Steel

- 2 Flutes

- B (Stub)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide tapered neck ball end mill, 2-flute / tapered neck model

MISUMI

[Features]

-High rigidity, 2 flute type with longitudinal taper

-It has coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating characteristics

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 2 Flutes

Configure nowStarting from∗ : 34.83 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

CBN Ball End Mill, 2-Flute

MISUMI

CBN ball end mill that's ideal for precision finishing is available at a value price- Volume Discount

- High-Hardness Steel

- 2 Flutes

Configure nowStarting from∗ : 136.38 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

2-Flute, Ball End, FX-MG-EBD

OSG

Can work with materials ranging from general materials to quenched steel. Can also be compatible with high speed model machining centers.- Volume Discount

Configure nowStarting from∗ : 91.40 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

2-Flute Long Neck Ball End (for High Rigidity) WXS-LN-EBD

OSG

Long neck ball which has been subjected to WX super coat of super-hard and ultra-heat-resistant. In accordance with the processing shape, freely effective length can be selected.- Volume Discount

Configure nowStarting from∗ : 57.40 € Min. Shipping Days : Same day *Unit price with basic configuration

-

2-Flute Long Neck Ball End (Deep Rib Ball) WXL-LN-EBD

OSG

Displays effectiveness on a wide range of uses such as metal mold machining to copper electrode processing thanks to the effects of the high hardness lubricating film WXL coating.- Volume Discount

Configure nowStarting from∗ : 49.20 € Min. Shipping Days : Same day *Unit price with basic configuration

-

SFB200 CBN Super Finish Ball End Mill

NS TOOL

The newly developed blade shape provides excellent sharpness through the radius center. Capable of finishing 60 HRC hardened steel for 10 continuous hours or moreConfigure nowStarting from∗ : 181.70 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

MSBH230 2-Flute Ball-End Mill for High-Hardness

NS TOOL

Standard type ball end mill for high hardness. Ideal for finishing- Volume Discount

- Stock

Configure nowStarting from∗ : 26.17 € Min. Shipping Days : Same day *Unit price with basic configuration

-

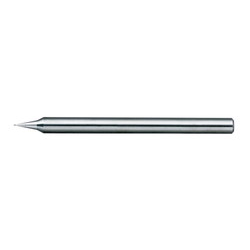

SMB120 CBN Ball End Mill CBN Micro Ball for Ultra-Fine Machining

NS TOOL

The world's first. Micro ball end mill made of CBN material. Achieves sharp edges by making the best use of the CBN material characteristicsConfigure nowStarting from∗ : 239.99 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

DHB Long Neck Ball End Mill for Copper Electrode / Aluminum / Plastic (for Deep Rib)

NS TOOL

[Features]

Long shank cutter with 2 cutting edges.

[Features]

Suitable for machining aluminium alloys, copper and resins.- Volume Discount

Configure nowStarting from∗ : 71.19 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 85.80 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

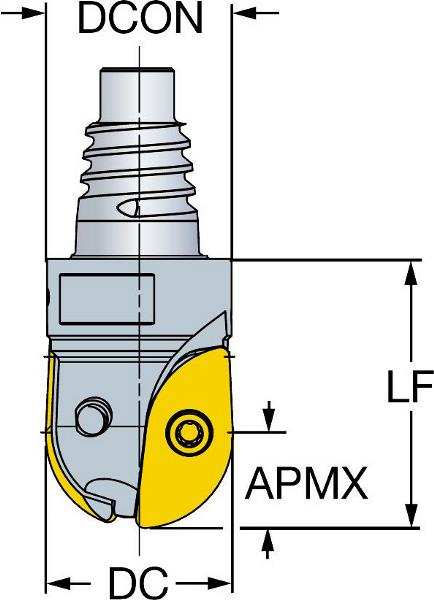

Ball End Mill, Center Cut, R216.4 (Hardness 43 HRC to 63 HRC), Cylindrical Shank

SANDVIK

- Volume Discount

Configure nowStarting from∗ : 104.97 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Configure now

Starting from∗ : 104.03 € Min. Shipping Days : 6 Days *Unit price with basic configuration

-

Carbide 2-Flute Medium Ball End Mill 30° B232X

7 LEADERS

[Features]

· 2-flute medium ball end mill that supports a wide range of work materials.

· Capable of continuous stable cutting.

· Nanoparticle multilayer coating.

· Excellent lubricity and abrasion resistance.

· Exhibits its strength in general cutting processes.- Volume Discount

Configure nowStarting from∗ : 28.87 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

EPL-PC-EBD, Carbide end mill

OSG

Carbide end mill - For general applications - 2 flutes, ball nose, pencil neckConfigure nowStarting from∗ : 54.60 € Min. Shipping Days : 2 Days *Unit price with basic configuration

-

Configure now

Min. Shipping Days : 5 Days -

TSC series carbide ball end mill (R accuracy ±3μm)

MISUMI

[Features]

-Radius tolerance within 6 µm (compared to manufacturer's measurements), shank diameter tolerance h5 standard adopted. Optimal for high precision 3D machining of moulds with high quality tools with low quality variation

-Seamless shape (sharpening from outer edge to centre of rounded blade in 1 process) is designed to create smooth cutting edge flank without steps.- Volume Discount

- TS

- General Steel

- 2 Flutes

- S (Short)

Configure nowStarting from∗ : 46.74 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TSC series carbide ball end mill (for shrink fit holder / R accuracy ±3 μm) 2-flute / stub model

MISUMI

[Features]

-Designed with optimum blade length, shank length and overall length considering processing with shrink fit holder

-Radius tolerance within 6 µm (compared to manufacturer's measurements), shank diameter tolerance h5 standard adopted. High-precision tools with low quality variation are ideal for high-precision 3D machining of moulds

-Sampless shape (sharpening from the outer edge to the centre of the rounded blade in one process) is designed to produce a smooth cutting edge without steps.- Volume Discount

- TS

- General Steel

- 2 Flutes

- B (Stub)

Configure nowStarting from∗ : 64.20 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TSC series carbide ball end mill, for shrinkage fitting, 2-flute / stub model

MISUMI

[Features]

-Compatible with shrink fit chucks for high precision machining

-Designed with short flute length and overall length for shrink fit and emphasis on rigidity

It has coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating characteristics.- Volume Discount

- TS

- General Steel

- 2 Flutes

- B (Stub)

Configure nowStarting from∗ : 24.07 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

XAL series carbide ball end mill, 2-flute / short model

MISUMI

XAL Series is the definitive choice for cost-sensitive customers- Volume Discount

- XAL

- General Steel

- 2 Flutes

Configure nowStarting from∗ : 15.04 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

XAC series carbide ball end mill, 2-flute / short model

MISUMI

[Features]

All-purpose ball nose end mill with 2 cutting edges for a wide range of profiling

-For rough machining of workpieces that are expected to have a good surface finish after machining

-Can be reground. Please refer to the "Regrinding Service" page for information on application methods, range of services, prices, etc.- Volume Discount

- TiAlN

- General Steel

- 2 Flutes

- S (Short)

Configure nowStarting from∗ : 23.03 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

XAC series carbide ball end mill, 2-flute / short, long shank model

MISUMI

[Features]

-Ideal for high precision 3D machining of moulds due to high tool rigidity and excellent chip evacuation

-For rough machining of the workpiece, a good surface finish can be expected after machining.

-Long shank type, ideal for deep cavity milling

-Can be reground. Please refer to the "Regrinding Service" page for information on application procedures, range of services, prices, etc.- Volume Discount

- TiAlN

- General Steel

- 2 Flutes

Configure nowStarting from∗ : 44.96 € Min. Shipping Days : 5 Days *Unit price with basic configuration

-

TSC series carbide ball end mill, short model

MISUMI

[Features]

-Good surface finish can be expected for the rough surface of the workpiece after machining

It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 2 Flutes

- S (Short)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, regular model

MISUMI

[Features]

-Regular bridge length allows for many regrinding times

-Can be regrinded. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 2 Flutes

- R (Regular)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, 2-flute / short, long shank model

MISUMI

[Features]

-Long shank, ideal for deep cavity milling

It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 2 Flutes

- S (Short)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, 3-flute / short model

MISUMI

[Features]

-The 3-edge shape is resistant to chattering and enables high feed rate

-The surface of the workpiece is very well finished after machining.

-The coating has high oxidation resistance and high hardness and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 3 Flutes

- S (Short)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, 3-flute / regular model

MISUMI

[Features]

-The 3-edge shape is chatter resistant and enables high feed

-The coating has high oxidation resistance and high hardness and achieves long life. Effective in high speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 3 Flutes

- R (Regular)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, short model

MISUMI

[Features]

-The surface of the workpiece is very good after machining.

-It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, performance range, prices, etc.- Volume Discount

- TS

- General Steel

- 4 Flutes

- S (Short)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide ball end mill, 4-flute / regular model

MISUMI

[Features]

-The surface of the workpiece is very good after machining.

-It has coating with high oxidation resistance and high hardness, and achieves long service life. As a coating property, it is effective in high-speed machining and dry machining.

-Can be reground. Please refer to the "Regrinding Service" page for application methods, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 4 Flutes

- R (Regular)

Configure nowMin. Shipping Days : 5 Days -

Carbide ball end mill, 2-flute / short model

MISUMI

Highly versatile due to the non-coated specification- Volume Discount

- Non-Coated

- General Steel

- 2 Flutes

- S (Short)

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide tapered neck ball end mill, 3-flute / tapered neck model

MISUMI

[Features]

-High feed, high rigidity 3-spiral taper shape with taper length

-It has coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, performance range, prices, etc.- Volume Discount

- TS

- General Steel

- 3 Flutes

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide long neck ball end mill, 2-flute / long neck model

MISUMI

[Features]

-Long neck shape suitable for deep cavity milling

-It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 2 Flutes

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide long neck ball end mill, 3-flute / long neck model

MISUMI

[Features]

-Long-neck ball with 3 cutting edges, suitable for high-speed machining of deep cutting areas

-The coating has high oxidation resistance and high hardness, and achieves long service life. Effective in high speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 3 Flutes

Configure nowMin. Shipping Days : 5 Days -

TSC series carbide long neck ball end mill, 4-flute / long neck model

MISUMI

[Features]

-Long Neck Ball 4-Flute type suitable for high-feed machining of deep cutting areas

-It has coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.- Volume Discount

- TS

- General Steel

- 4 Flutes

Configure nowMin. Shipping Days : 5 Days -

TS Coated Carbide Ball End Mill, Cutting Edge Rigidity Machining / For High-Hardness Steel Machining, 2-Flute / No Side Blade

MISUMI

[Features]

-Ultra-fine-grained carbide base material suitable for machining high hardness steels is used (according to the manufacturer's cutting test results).

-MIAutomatic steelI-Original shape with rigid cutting edge treatment and no side cutting edge. High strength of the tool and cutting edge, resulting in a stable cutting edge shape and long tool life in high-speed milling

-Can be reground. Please refer to the "Regrinding Service" page for information on application methods, range of services, prices, etc.- Volume Discount

- TS

- High-Hardness Steel

- 2 Flutes

Configure nowStarting from∗ : 113.26 € Min. Shipping Days : 5 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days |

| Specifications |

| R Size(mm) |

| Type |

| work material |

| Blade length (ℓ)(mm) |

| Number of flutes(sheet) |

| Coating |

| Overall Length (L)(mm) |

| Underneck length (ℓ1)(mm) |

| Shank diameter (d)(mm) |

| R Precision(μm) |

| Machining Application |

| Brand | EIKOSHA | OSG | UNION TOOL | EIKOSHA | KYOWA SEIKO | OSG | NS TOOL | EIKOSHA | NS TOOL | SANDVIK | MISUMI | MISUMI | MISUMI | OSG | OSG | OSG | NS TOOL | NS TOOL | NS TOOL | NS TOOL | EIKOSHA | SANDVIK | SANDVIK | 7 LEADERS | OSG | SANDVIK | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | TSC series carbide ball end mill, spherical, 2-flute / stub, long neck model | TSC series carbide tapered neck ball end mill, 2-flute / tapered neck model | SMB120 CBN Ball End Mill CBN Micro Ball for Ultra-Fine Machining | DHB Long Neck Ball End Mill for Copper Electrode / Aluminum / Plastic (for Deep Rib) | Ball End Mill, Center Cut, R216.4 (Hardness 43 HRC to 63 HRC), Cylindrical Shank | CoroMill Plura, Ball End Mill, Center Cut, RA216.42 (Hardness < 63 HRC) | TSC series carbide ball end mill (for shrink fit holder / R accuracy ±3 μm) 2-flute / stub model | TSC series carbide ball end mill, for shrinkage fitting, 2-flute / stub model | XAC series carbide ball end mill, 2-flute / short, long shank model | TSC series carbide ball end mill, 2-flute / short, long shank model | TSC series carbide tapered neck ball end mill, 3-flute / tapered neck model | TSC series carbide long neck ball end mill, 2-flute / long neck model | TSC series carbide long neck ball end mill, 3-flute / long neck model | TSC series carbide long neck ball end mill, 4-flute / long neck model | |||||||||||||||||||||||||||||||

| Starting from∗ | 106.58 € *Unit price with basic configuration Volume Discount | 98.58 € *Unit price with basic configuration | 28.03 € *Unit price with basic configuration Volume Discount | 128.66 € *Unit price with basic configuration Volume Discount | 152.07 € *Unit price with basic configuration | 121.20 € *Unit price with basic configuration Volume Discount | 26.97 € *Unit price with basic configuration Volume Discount | 145.23 € *Unit price with basic configuration | 172.90 € *Unit price with basic configuration | 513.00 € *Unit price with basic configuration | - Volume Discount | 34.83 € *Unit price with basic configuration Volume Discount | 136.38 € *Unit price with basic configuration Volume Discount | 91.40 € *Unit price with basic configuration Volume Discount | 57.40 € *Unit price with basic configuration Volume Discount | 49.20 € *Unit price with basic configuration Volume Discount | 181.70 € *Unit price with basic configuration | 26.17 € *Unit price with basic configuration Volume Discount | 239.99 € *Unit price with basic configuration | 71.19 € *Unit price with basic configuration Volume Discount | 85.80 € *Unit price with basic configuration Volume Discount | 104.97 € *Unit price with basic configuration Volume Discount | 104.03 € *Unit price with basic configuration Volume Discount | 28.87 € *Unit price with basic configuration Volume Discount | 54.60 € *Unit price with basic configuration | - | 46.74 € *Unit price with basic configuration Volume Discount | 64.20 € *Unit price with basic configuration Volume Discount | 24.07 € *Unit price with basic configuration Volume Discount | 15.04 € *Unit price with basic configuration Volume Discount | 23.03 € *Unit price with basic configuration Volume Discount | 44.96 € *Unit price with basic configuration Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | - Volume Discount | 113.26 € *Unit price with basic configuration Volume Discount |

| Min. Shipping Days | 6 Days | 6 Days | Same day | 6 Days | 7 Days | 6 Days | Same day | 6 Days | 6 Days | 5 Days | 5 Days | 5 Days | 5 Days | 6 Days | Same day | Same day | 6 Days | Same day | 6 Days | 6 Days | 6 Days | 6 Days | 6 Days | 8 Days | 2 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days | 5 Days |

| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||

| R Size(mm) | 0.5 ~ 10 | 8 ~ 10 | 0.05 ~ 3 | 3 ~ 10 | 0.1 ~ 1.5 | 0.5 ~ 6 | 0.05 ~ 3 | 3 ~ 10 | 0.1 ~ 3 | - | 0.5 ~ 5 | 0.15 ~ 5 | 0.3 ~ 1 | 0.5 ~ 15 | 0.1 ~ 3 | 0.05 ~ 3 | 0.1 ~ 1 | 0.05 ~ 6 | 0.01 ~ 0.05 | 0.5 ~ 3 | 0.4 ~ 20 | 0.5 ~ 8 | 0.2 ~ 0.5 | 0.5 ~ 10 | - | - | 1.5 ~ 3 | 0.3 ~ 2 | 0.2 ~ 6 | 0.05 ~ 10 | 0.2 ~ 12.5 | 2 ~ 8 | 0.05 ~ 10 | 0.2 ~ 8 | 0.5 ~ 12.5 | 0.5 ~ 10 | 1 ~ 6 | 1 ~ 10 | 1.5 ~ 6 | 0.2 ~ 10 | 0.5 ~ 3 | 0.05 ~ 3 | 0.5 ~ 3 | 1 ~ 3 | 1 ~ 5 |

| Type | Spherical Ball | Spherical Ball | Long-Neck Ball | Spherical Ball | Ball | Spherical Ball | Long-Neck Ball | Spherical Ball | Ball | - | Long-Neck Ball / Spherical Ball | Tapered neck ball | Ball | Ball | Long-Neck Ball | Long-Neck Ball | Ball | Ball | Ball | Long-Neck Ball | Ball | Tapered neck ball | Long-Neck Ball | Ball | - | - | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Ball | Tapered neck ball | Long-Neck Ball | Long-Neck Ball | Long-Neck Ball | Ball |

| work material | - | General Steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] / Stainless Steel[○] / Cast Iron[○] / Titanium[○] / Copper[○] | - | High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Titanium[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] / Stainless Steel[◎] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] | - | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] | - | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[○] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[◎] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] / Stainless Steel[○] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] / Stainless Steel[○] | Aluminum[◎] / Copper[◎] / Resin[◎] | General Steel[◎] / Quenched and tempered steel[○] / Cast Iron[○] / Aluminum[◎] / Copper[◎] | General Steel[○] / Quenched and tempered steel[○] / High Hardness Steel: to HRC60[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[○] / High Hardness Steel: to HRC60[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] / Resin[○] | - | - | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[○/◎] / Resin[○] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] | General Steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel: to HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | General Steel[○] / Quenched and tempered steel[○] / High Hardness Steel: to HRC55[◎] / High Hardness Steel: to HRC60[◎] / High Hardness Steel: to HRC65[◎] / Stainless Steel[○] / Cast Iron[◎] |

| Blade length (ℓ)(mm) | - | 12 ~ 15 | 0.08 ~ 4.8 | - | 0.2 ~ 2 | 0.7 ~ 8.1 | 0.07 ~ 6 | - | 0.15 ~ 3.6 | 7.874 ~ 45.49 | - | 0.3 ~ 8 | 0.5 ~ 1.2 | 2.5 ~ 55 | 0.16 ~ 4.8 | 0.08 ~ 6 | 0.15 ~ 1.2 | 0.1 ~ 20 | 0.02 ~ 0.1 | 1.5 ~ 9 | 3 ~ 70 | 1 ~ 16 | 0.3 ~ 1 | 2 ~ 38 | - | 1.19 ~ 4.8 | 4.5 ~ 9 | 0.6 ~ 4 | 0.4 ~ 12 | 0.2 ~ 38 | 0.8 ~ 50 | 8 ~ 30 | 0.2 ~ 25 | 1.5 ~ 30 | 2 ~ 30 | 2 ~ 25 | 5 ~ 22 | 3 ~ 25 | 5 ~ 22 | 0.8 ~ 25 | 0.8 ~ 6 | 0.07 ~ 8 | 0.8 ~ 4.8 | 1.6 ~ 6 | 1 ~ 5 |

| Number of flutes(sheet) | 2 | 2 | 2 | 4 | 2 | 2 | 2 | 2 | 2 | - | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 ~ 4 | 2 | 2 | - | - | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 4 | 2 | 3 | 2 | 2 ~ 3 | 4 | 2 |

| Coating | - | For General Steels (AlCrN, etc.) | For High Hardness (Silicon Group) | - | - | TiAlN | For High Hardness (Silicon Group) | - | Non-Coated | - | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | Non-Coated | TiAlN | For High Hardness (Silicon Group) | For General Steels (AlCrN, etc.) | Non-Coated | For High Hardness (Silicon Group) | Non-Coated | Non-Coated | - | Other | Other | - | - | - | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For General Steels (AlCrN, etc.) | TiAlN | TiAlN | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | Non-Coated | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) |

| Overall Length (L)(mm) | 70 ~ 100 | 49 ~ 58 | 45 ~ 120 | 70 ~ 100 | 50 ~ 60 | 60 ~ 110 | 45 ~ 120 | 100 ~ 130 | 50 ~ 70 | 20 ~ 50 | 70 ~ 90 | 50 ~ 110 | 50 | 50 ~ 180 | 45 ~ 90 | 45 ~ 120 | 50 ~ 52 | 50 ~ 100 | 50 | 50 ~ 110 | 45 ~ 180 | 57 ~ 140 | 54 ~ 57 | 50 ~ 160 | - | - | 60 ~ 90 | 40 | 40 ~ 65 | 40 ~ 160 | 40 ~ 180 | 100 ~ 250 | 40 ~ 150 | 50 ~ 140 | 70 ~ 280 | 50 ~ 150 | 50 ~ 110 | 50 ~ 150 | 60 ~ 110 | 40 ~ 150 | 50 ~ 110 | 40 ~ 110 | 50 ~ 110 | 50 ~ 70 | 50 ~ 90 |

| Underneck length (ℓ1)(mm) | 4 ~ 42 | - | 0.3 ~ 60 | 18 ~ 42 | - | 5 ~ 60 | 0.2 ~ 50 | 18 ~ 42 | 0.3 ~ 18 | - | 4 ~ 55 | 1.5 ~ 60 | 1.5 ~ 5 | - | 0.5 ~ 40 | 0.3 ~ 50 | 0.5 ~ 5 | - | - | 4 ~ 50 | - | 20 | 1 ~ 10 | - | - | - | - | - | - | - | - | - | 15 ~ 75 | 17 ~ 80 | 15 ~ 80 | 15 ~ 75 | 17 ~ 72 | 15 ~ 75 | 17 ~ 72 | - | 7 ~ 60 | 0.2 ~ 60 | 3 ~ 50 | 4 ~ 30 | 5 ~ 10 |

| Shank diameter (d)(mm) | 4 ~ 16 | 10 ~ 12 | 3 ~ 6 | 6 ~ 16 | 4 | 6 ~ 12 | 4 ~ 6 | 6 ~ 16 | 4 | 9.52 ~ 50.8 | 6 ~ 10 | 4 ~ 12 | 4 | 4 ~ 25 | 4 ~ 6 | 3 ~ 6 | 4 | 4 ~ 12 | 4 | 4 ~ 8 | 4 ~ 32 | 4 ~ 16 | 6 | 6 ~ 20 | - | 7.94 ~ 30/32 | 6 | 6 | 4 ~ 12 | 3 ~ 20 | 3 ~ 25 | 4 ~ 16 | 3 ~ 20 | 4 ~ 16 | 3 ~ 25 | 6 ~ 20 | 6 ~ 12 | 6 ~ 20 | 6 ~ 12 | 3 ~ 20 | 4 ~ 8 | 3 ~ 8 | 4 ~ 6 | 4 ~ 6 | 6 ~ 10 |

| R Precision(μm) | ±0.01 ~ ±0.02 | -0.01~+0.01 | -0.005~0.005 ~ -0.002~0.002 | ±0.01 ~ ±0.02 | +0.005~-0.005 | - | 0.005~-0.005 | ±0.01 ~ ±0.02 | 0.05~-0.05 ~ 5 to -5 | - | ±0.01 | -0.007 ~ +0.003 ~ ±0.005 | ±0.005 | -0.01~+0.01 | -0.005~+0.005 | -0.005~+0.005 | 0.003~-0.003 ~ 0.005~-0.005 | 0.005~-0.005 ~ 0.01~-0.01 | - | 0.01~-0.01 | ±0.02 | - | - | ±10 | - | - | -0.005 ~ +0.001 ~ ±0.003 | ±0.003 | -0.007 ~ +0.003 ~ ±0.005 | -0.007 ~ +0.003 ~ ±0.01 | ±0.01 | ±0.01 | -0.007 ~ +0.003 ~ ±0.01 | -0.007 ~ +0.003 ~ ±0.01 | -0.007 ~ +0.003 ~ ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | -0.007 ~ +0.003 ~ ±0.005 | -0.007 ~ +0.003 ~ ±0.005 | -0.007 ~ +0.003 ~ ±0.005 | -0.007 ~ +0.003 ~ ±0.005 | ±0.01 |

| Machining Application | - | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | - | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | - | Curved surface / Side / Engraving / R Groove | - | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface | Curved surface | Curved surface / Engraving / R Groove | - | - | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove | Curved surface / Side / Engraving / R Groove |

Loading...

Filter by:

Stock

-

- Show only stock items

-

R Size(mm)

- 0.005

- 0.01

- 0.015

- 0.02

- 0.025

- 0.03

- 0.04

- 0.05

- R0.05

- 0.075

- 0.1

- R0.1

- 0.125

- 0.15

- R0.15

- 0.175

- 0.2

- R0.2

- 0.225

- 0.25

- R0.25

- 0.275

- 0.3

- R0.3

- 0.325

- 0.35

- R0.35

- 0.375

- 0.4

- R0.4

- 0.425

- 0.45

- R0.45

- 0.475

- 0.5

- R0.5

- 0.55

- R0.55

- 0.6

- R0.6

- 0.65

- R0.65

- 0.7

- R0.7

- 0.75

- R0.75

- 0.8

- R0.8

- 0.85

- R0.85

- 0.9

- R0.9

- 0.95

- R0.95

- 1

- R1

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- R1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- R2

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- R2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.55

- 2.6

- 2.65

- 2.7

- 2.75

- R2.75

- 2.8

- 2.85

- 2.9

- 2.95

- 3

- R3

- R 3.0

- 3.05

- 3.1

- 3.15

- 3.175

- 3.2

- 3.25

- R3.25

- 3.3

- 3.35

- 3.4

- 3.45

- 3.5

- R3.5

- 3.55

- 3.6

- 3.65

- 3.7

- 3.75

- R3.75

- 3.8

- 3.85

- 3.9

- 3.95

- 4

- R4

- R 4.0

- 4.05

- 4.1

- 4.15

- 4.2

- 4.25

- R4.25

- 4.3

- 4.35

- 4.4

- 4.45

- 4.5

- R4.5

- 4.55

- 4.6

- 4.65

- 4.7

- 4.75

- 4.8

- 4.85

- 4.9

- 4.95

- 5

- R5

- 5.05

- 5.1

- 5.15

- 5.2

- 5.25

- 5.3

- 5.35

- 5.4

- 5.45

- 5.5

- R5.5

- 5.55

- 5.6

- 5.65

- 5.7

- 5.75

- 5.8

- 5.85

- 5.9

- 5.95

- 6

- R6

- 6.05

- 6.1

- 6.15

- 6.2

- 6.25

- 6.3

- 6.35

- 6.4

- 6.45

- 6.5

- 6.55

- 6.6

- 6.65

- 6.7

- 6.75

- 6.8

- 6.85

- 6.9

- 6.95

- 7

- R7

- 7.05

- 7.1

- 7.15

- 7.2

- 7.25

- 7.3

- 7.35

- 7.4

- 7.45

- 7.5

- 7.55

- 7.6

- 7.65

- 7.7

- 7.75

- 7.8

- 7.85

- 7.9

- 7.95

- 8

- R8

- 8.05

- 8.1

- 8.15

- 8.2

- 8.25

- 8.3

- 8.35

- 8.4

- 8.45

- 8.5

- 8.55

- 8.6

- 8.65

- 8.7

- 8.75

- 8.8

- 8.85

- 8.9

- 8.95

- 9

- R9

- 9..5

- 9.05

- 9.1

- 9.15

- 9.2

- 9.25

- 9.3

- 9.35

- 9.4

- 9.45

- 9.5

- 9.55

- 9.6

- 9.65

- 9.7

- 9.75

- 9.8

- 9.85

- 9.9

- 9.95

- 10

- R10

- 10.25

- 10.5

- 10.75

- 11

- 11.5

- 12

- 12.25

- 12.5

- 12.75

- 13

- 13.5

- 14

- 14.5

- 15

- 15.5

- 16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 22.0

- 22.5

- 23.0

- 24.0

- 25

-

Type

-

work material

-

Blade length (ℓ)(mm)

-

0.01~0.96

- 0.01

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.1

- 0.12

- 0.15

- 0.16

- 0.2

- 0.23

- 0.24

- 0.3

- 0.32

- 0.35

- 0.38

- 0.4

- 0.45

- 0.48

- 0.5

- 0.56

- 0.6

- 0.63

- 0.64

- 0.65

- 0.7

- 0.72

- 0.75

- 0.76

- 0.8

- 0.9

- 0.95

- 0.96

-

1~1.9

- 1

- 1.1

- 1.12

- 1.19

- 1.2

- 1.25

- 1.26

- 1.28

- 1.3

- 1.4

- 1.42

- 1.44

- 1.45

- 1.5

- 1.6

- 1.7

- 1.75

- 1.8

- 1.9

-

2~2.9

- 2

- 2.1

- 2.2

- 2.25

- 2.3

- 2.39

- 2.4

- 2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.85

- 2.9

-

3~3.9

- 3

- 3.2

- 3.25

- 3.5

- 3.6

- 3.7

- 3.75

- 3.8

- 3.81

- 3.85

- 3.9

-

4~4.9

- 4

- 4.1

- 4.2

- 4.25

- 4.4

- 4.5

- 4.7

- 4.75

- 4.8

- 4.9

-

5~5.9

- 5

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.7

- 5.8

- 5.9

-

6~6.9

- 6

- 6.2

- 6.25

- 6.3

- 6.5

- 6.6

- 6.7

- 6.8

- 6.9

-

7~7.874

- 7

- 7.1

- 7.2

- 7.4

- 7.5

- 7.874

-

8~8.9

- 8

- 8.1

- 8.2

- 8.3

- 8.4

- 8.5

- 8.6

- 8.7

- 8.9

-

9~9.7

- 9

- 9.5

- 9.7

-

10~10.8

- 10

- 10.5

- 10.8

-

11~11.5

- 11

- 11.2

- 11.278

- 11.28

- 11.3

- 11.5

-

12~12.7

- 12

- 12.5

- 12.7

-

13~13.5

- 13

- 13.5

-

14~14.5

- 14

- 14.199

- 14.2

- 14.4

- 14.5

-

15

-

16~16.993

- 16

- 16.5

- 16.99

- 16.993

-

17~17.9

- 17

- 17.5

- 17.9

-

18

-

19

-

20

-

21~21.5

- 21

- 21.5

-

22~22.682

- 22

- 22.3

- 22.68

- 22.682

-

23

-

24

-

25

-

26~26.9

- 26

- 26.9

-

27

-

28~28.6

- 28

- 28.296

- 28.3

- 28.6

-

29

-

30

-

31.6

-

32

-

33

-

34

-

35

-

36~36.5

- 36

- 36.5

-

38

-

40

-

44.6

-

45~45.49

- 45

- 45.49

-

48

-

50

-

55

-

58

-

60

-

65

-

70

-

80

-

90

-

100

-

110

-

120

-

130

[5-30/1mm Unit(s)]

-

-

Number of flutes(sheet)

-

Coating

-

Overall Length (L)(mm)

-

Underneck length (ℓ1)(mm)

-

Shank diameter (d)(mm)

-

R Precision(μm)

-

Machining Application

Brand

CAD data type

-

- 2D

- 3D