- R Size(mm)

- 0.5

- 0.75

- 1

- 1.5

- 2

- 3

- Flute Length (ℓ)(mm)

- 0.8

- 1.2

- 1.6

- 2.4

- 3.2

- 4.8

- Overall Length (L)(mm)

- 70

- 110

- Length Under Neck (ℓ1)(mm)

- 20

- 30

- 40

- 46

- 50

- Shank Diameter (d)(mm)

- 4

- 6

- 8

- R Precision(μm)

- Type

- Est. shipping days

- All

- Within 5 working days

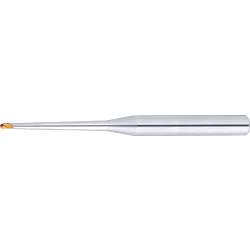

TSC Series Carbide Tapered Neck Ball End Mill, for High-Hardness Steel, 3-Flute / Tapered Neck Model

Part number:

possible part numbers found.Outline drawing

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

73.70 € ( 87.70 € ) | 5 working days |

75.63 € ( 90.00 € ) | 5 working days |

71.52 € ( 85.11 € ) | 5 working days |

81.09 € ( 96.50 € ) | 5 working days |

103.54 € ( 123.21 € ) | 5 working days |

94.29 € ( 112.21 € ) | 5 working days |

82.75 € ( 98.47 € ) | 5 working days |

101.29 € ( 120.54 € ) | 5 working days |

96.95 € ( 115.37 € ) | 5 working days |

124.22 € ( 147.82 € ) | 5 working days |

91.75 € ( 109.18 € ) | 5 working days |

More Information

Basic information

[Features]

The shape with 3 flutes and short flute length prevents chatter and enables high feed machining

The tapered neck effectively suppresses chatter

Machining of high hardness steel up to 65HRC is possible

The coating has high oxidation resistance and high hardness and achieves long life. Effective in high speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for information on procedures, scope of services, pricing, etc.

Specifications and price

Specifications

| Model Number | Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | ||

| Outer Diameter D |

Radius R |

|||||

| TSC-SHP-CR-HFEM4B | 2 | 0.2 | 3 | 50 | 6 | 1 |

| 3 | 0.2 | 4.5 | 50 | 6 | 1 | |

| 4 | 0.5 | 6 | 50 | 6 | 1 | |

| 6 | 0.5 | 9 | 50 | 6 | 2 |

For Cutting Conditions, Refer to >>Click here.

Features and usage examples

More Information

● It is designed to have an ideal flute length, shank length and overall length, keeping in mind the usage of a shrink fit holder for processing.

● A radius (R) accuracy within 5 μm (our measured ratio) / shank diameter, tolerance h5 standard, has been adopted. The highly accurate tools with minimal quality variation are suitable for realizing high-accuracy, high-precision machining.

● Designed to have a blade shape with an emphasis on rigidity thanks to the radius (R) model negative blade, they are suitable for machining heat-treated steel / high hardness steel.

● The TS coat consisting of a nitride-based composite film with a fully crystalline structure means that it realizes a high oxidation resistance temperature and high hardness. It is ideal for high speed machining and dry machining of heat-treated / high hardness steel.