- Number of Teeth(Teeth)

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 32

- 33

- 34

- 35

- 36

- 38

- 39

- 40

- 42

- 44

- 45

- 46

- 48

- 49

- 50

- 51

- 52

- 54

- 55

- 56

- 57

- 58

- 60

- 62

- 63

- 64

- 65

- 66

- 68

- 69

- 70

- 72

- 75

- 76

- 77

- 78

- 80

- Material (Details)

- Stainless Steel

- EN 1.4301 Equiv.

- Surface Treatment

- Shaft Bore Dia.(Ø)

- 8

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

[8-60/1Ø units] - Tooth Width B(mm)

- 20

- 25

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 7 working days

Spur Gears / Contact Angle 20 Degrees / Module 2.5(Part number list: 25 page)

Part number:

possible part numbers found.Outline drawing and specifications table

Dimensional Drawing

[NG] Tapped shaft bores are not available for Shape A

| Shaft Bore Specifications (Selectable Gear Shapes) | |

| Straight Bore (Shape A, Shape B) | Straight Bore + Tap (Shape B) |

|  |

| Keyway (Shape A) | Keyway + Tap (Shape B) |

|  |

To match, specify GBA for alteration.

Tooth surface accuracy Equivalent to the new JIS B 1702-1 Class 8

(Old JIS B 1702 Class 4)

| Nominal | PH7 |

| 8 N to 10K | +0.015 0 |

| 11 N to 18 N | +0.018 0 |

| 19 N to 30 N | +0.021 0 |

| 31 N to 50 N | +0.025 0 |

| Nominal | bJS9 | t | ||

| 8 N to 10 N | 3 | ±0.0125 | 1.4 | +0.1 0 |

| 10K to 12 N | 4 | ±0.0150 | 1.8 | |

| 13 N to 17 N | 5 | 2.3 | ||

| 18 N to 22 N | 6 | 2.8 | ||

| 23 N to 30 N | 8 | ±0.0180 | 3.3 | +0.2 0 |

| 31 N to 38 N | 10 | |||

| 39 N to 44 N | 12 | ±0.0215 | ||

| 45 N to 50 N | 14 | 3.8 | ||

| Dimension Range | Tolerance (mm) | |

| Over | or Less | |

| 0.5 | 3 | ±0.1 |

| 3 | 6 | ±0.1 |

| 6 | 30 | ±0.2 |

| 30 | 120 | ±0.3 |

| 120 | 400 | ±0.5 |

| Type | [M] Material | [S] Surface Treatment | [A]Accessory | ||

| Straight Bore | Straight Bore + Tap | Keyway, Keyway + Tap | |||

| GEAHB | GEAB | GEAKB | EN 1.1191 Equiv. | — | Set Screw (EN 1.7220 Equiv., Black Oxide) |

| GEAHBB | GEABB | GEAKBB | Black Oxide | ||

| GEAHBG | GEABG | GEAKBG | Electroless Nickel Plating | ||

| GEAHS | GEAS | GEAKS | EN 1.4301 Equiv. | — | Set Screw (EN 1.4301 Equiv.) |

[ ! ] The set screw is included for shaft hole specification "Tapped."

Specification Table

| Part Number | — | Number of Teeth | — | B | — | Gear Shape | — | P |

| GEAB2.5 GEAKB2.5 | — — | 15 30 | — — | 25 25 | — — | B A | — — | 8 10 N |

| Part Number | Number of Teeth | B | Gear Shape | Shaft Bore Dia. PH7 Unit: mm | d Reference Circle Dia. | D Addendum Circle Dia. | G Dedendum Circle Dia. | H | L | ℓ1 | ℓ2 | M (Coarse) | * 1 Allowable Transmission Force (N⋅m) Bending Strength | |||

| Type | Module | Straight Bore Straight Bore + Tap | Keyway Keyway + Tap | S45C Equivalent | SUS304 | |||||||||||

| Straight Bore (Shape A, Shape B) GEAHB GEAHBB GEAHBG GEAHS Straight Bore + Tap (Shape B) GEAB GEABB GEABG GEAS Keyway (Shape A) Keyway + Tap (Shape B) GEAKB GEAKBB GEAKBG GEAKS | 2.5 | 12 | 20 25 | A B | 8 to 13 | 8 N | 30 | 35 | 23.75 | 23 | 32 (B=20) 37 (B=25) | 12 | 6 | M5 | 30.86 | 17.61 |

| 13 | 32.5 | 37.5 | 26.25 | 35.38 | 20.19 | |||||||||||

| 14 | 8 to 15 | 8 N to 12 N・10K | 35 | 40 | 28.75 | 25 | 36 (B=20) 41 (B=25) | 16 | 8 | 40.03 | 22.85 | |||||

| 15 | 8 to 20 | 8 N to 15 N・10K | 37.5 | 42.5 | 31.25 | 30 | 44.78 | 25.55 | ||||||||

| 16 | 8 to 22 | 8 N to 17 N・10K | 40 | 45 | 33.75 | 32 | 49.60 | 28.30 | ||||||||

| 17 | 8 to 24 | 8 N to 19 N・10K | 42.5 | 47.5 | 36.25 | 35 | 54.51 | 31.10 | ||||||||

| 18 | 8 to 26 | 8 N to 22 N・10K | 45 | 50 | 38.75 | 38 | 59.50 | 33.95 | ||||||||

| 19 | 8 to 27 | 47.5 | 52.5 | 41.25 | 39 | 64.54 | 36.82 | |||||||||

| 20 | 8 to 28 | 8 N to 23 N・10K | 50 | 55 | 43.75 | 40 | 69.63 | 39.74 | ||||||||

| 21 | 8 to 30 | 8 N to 27 N・10K | 52.5 | 57.5 | 46.25 | 42 | 74.76 | 42.66 | ||||||||

| 22 | 8 to 32 | 8 N to 29 N・10K | 55 | 60 | 48.75 | 44 | 79.97 | 45.63 | ||||||||

| 23 | 8 to 34 | 8 N to 30 N・10K | 57.5 | 62.5 | 51.25 | 46 | 85.18 | 48.61 | ||||||||

| 24 | 8 to 36 | 8 N to 32 N・10K | 60 | 65 | 53.75 | 48 | 90.46 | 51.62 | ||||||||

| 25 | 8 to 38 | 8 N to 33 N・10K | 62.5 | 67.5 | 56.25 | 50 | M6 | 95.78 | 54.66 | |||||||

| 26 | 8 to 43 | 8 N to 37 N・10K | 65 | 70 | 58.75 | 55 | 101.10 | 57.70 | ||||||||

| 27 | 8 to 48 | 8 N to 40 N・10K | 67.5 | 72.5 | 61.25 | 60 | 106.50 | 60.78 | ||||||||

| 28 | 70 | 75 | 63.75 | 111.92 | 63.87 | |||||||||||

| 29 | 8 to 49 | 8 N to 41 N・10K | 72.5 | 77.5 | 66.25 | 62 | 117.35 | 66.97 | ||||||||

| 30 | 8 to 51 | 8 N to 43 N・10K | 75 | 80 | 68.75 | 65 | 122.78 | 70.06 | ||||||||

| 32 | 8 to 55 | 8 N to 47 N・10K | 80 | 85 | 73.75 | 70 | 133.78 | 76.34 | ||||||||

| 33 | 82.5 | 87.5 | 76.25 | 139.28 | 79.48 | |||||||||||

| 34 | 10 to 55 | 10 N to 47 N 10K | 85 | 90 | 78.75 | 144.86 | 82.66 | |||||||||

| 35 | 87.5 | 92.5 | 81.25 | 150.39 | 85.82 | |||||||||||

| 36 | 10 to 57 | 10 N to 49 N 10K | 90 | 95 | 83.75 | 75 | 155.98 | 89.01 | ||||||||

| 38 | 95 | 100 | 88.75 | 167.22 | 95.42 | |||||||||||

| 39 | 97.5 | 102.5 | 91.25 | 172.86 | 98.64 | |||||||||||

| 40 | 10 to 60 | 10 N to 50 N 10K | 100 | 105 | 93.75 | 80 | 178.46 | 101.84 | ||||||||

| 42 | 105 | 110 | 98.75 | 189.76 | 108.29 | |||||||||||

| 44 | 110 | 115 | 103.75 | 201.16 | 114.79 | |||||||||||

| 45 | 112.5 | 117.5 | 106.25 | 206.83 | 118.03 | |||||||||||

| 46 | 115 | 120 | 108.75 | 212.54 | 121.29 | |||||||||||

| 48 | 120 | 125 | 113.75 | 85 | 224.00 | 127.82 | ||||||||||

| 49 | 122.5 | 127.5 | 116.25 | 229.73 | 131.10 | |||||||||||

| 50 | 12 to 60 | 12 N to 50 N | 125 | 130 | 118.75 | 235.50 | 134.38 | |||||||||

| 51 | 15 N to 50 N | 127.5 | 132.5 | 121.25 | 241.19 | 137.64 | ||||||||||

| 52 | 15 to 60 | 130 | 135 | 123.75 | 246.91 | 140.90 | ||||||||||

| 54 | 135 | 140 | 128.75 | 258.45 | 147.49 | |||||||||||

| 55 | 137.5 | 142.5 | 131.25 | 264.26 | 150.80 | |||||||||||

| 56 | 140 | 145 | 133.75 | 270.10 | 154.13 | |||||||||||

| 57 | 142.5 | 147.5 | 136.25 | 275.85 | 157.41 | |||||||||||

| 58 | 145 | 150 | 138.75 | 281.62 | 160.70 | |||||||||||

| 60 | 25 to 60 | 25 N to 50 N | 150 | 155 | 143.75 | 293.22 | 167.33 | |||||||||

| 62 | 155 | 160 | 148.75 | 304.93 | 174.01 | |||||||||||

| 63 | 157.5 | 162.5 | 151.25 | 310.68 | 177.29 | |||||||||||

| 64 | 160 | 165 | 153.75 | 316.58 | 180.66 | |||||||||||

| 65 | 162.5 | 167.5 | 156.25 | 322.38 | 183.96 | |||||||||||

| 66 | 165 | 170 | 158.75 | 328.18 | 187.28 | |||||||||||

| 68 | 170 | 175 | 163.75 | 339.84 | 193.93 | |||||||||||

| 69 | 172.5 | 177.5 | 166.25 | 345.70 | 197.27 | |||||||||||

| 70 | 175 | 180 | 168.75 | 351.58 | 200.63 | |||||||||||

| 72 | 180 | 185 | 173.75 | 363.22 | 207.27 | |||||||||||

| 75 | 187.5 | 192.5 | 181.25 | 380.88 | 217.35 | |||||||||||

| 76 | 190 | 195 | 183.75 | 386.69 | 220.66 | |||||||||||

| 77 | 192.5 | 197.5 | 186.25 | 302.06 | 172.37 | |||||||||||

| 78 | 195 | 200 | 188.75 | 306.54 | 174.93 | |||||||||||

| 80 | 200 | 205 | 193.75 | 315.54 | 180.06 | |||||||||||

[!] Specify 10K as P dimension if keyway width of 4.0 mm (height 1.8 mm) for Keyway + Tap with shaft bore diameter of 10 is desired.

* 1 Allowable Transmission Forces in the table are reference values calculated by assuming a tooth width as 20 mm under the prescribed conditions.

Alterations

| Alterations | Set Screw Alteration | Tapped Hole Dimension Change | Root matching | |||||

| Code | KC90·KC120 | TPC | GBA | |||||

| Spec. | KC90: Adds another set screw at 90° position. KC120: Adds another set screw at 120° position. A set screw is added. Ordering Code KC90 Applicable Conditions [NG] Not applicable to Shape A [NG] Not applicable to Straight Bore Type KC90 KC20 | Changes the tapped hole dimension. Ordering Code TPC4 Applicable Conditions [NG] Not applicable to Shape A [NG] Not applicable to Straight Bore Type Standard Conditions [ ! ] ℓ1 - ℓ2 > TPC/2 | Align the bottom of the gear tooth with the keyway and tap phase. Phase Adjustment Tolerance ±0.3 (Reference Value) Ordering Code GBA Applicable Conditions [ ! ] Applicable to 19 teeth or more | |||||

|

|  |

| Alterations | Stepped Hole | Both Ends Stepped Hole | Hub Cut | ||||||||||||||||

| Code | DHL·DHR | WDH | BS | ||||||||||||||||

| Spec. | Changes shaft bores to stepped bores. Dimension Increments Z: 1 mm Increments J: 0.1 mm Increments Ordering Code DHL-Z20-4.0 Applicable Conditions [ ! ] Applicable only to Straight Bore Type [NG] Not applicable to Shape K Standard conditions

| Changes shaft bores to both ends stepped hole. Dimension Increments Q, R, S, T: 1 mm Increments S, T ≥ 3 Ordering Code WDH-Q10-R10-S3-T3 Applicable Conditions [ ! ] Applicable only to Straight Bore Type [NG] Not applicable to Shape K Standard conditions

| Cuts the hub length to the specified length. Increments 0.5 mm Ordering Code BS6.5 Applicable Conditions [NG] Not applicable to Shape A, K Standard conditions [!] Straight Bore: 0 ≤ BS ≤ ℓ1 [!] Straight Bore + Tapped Type: BS=0; M+3 ≤ BS ≤ ℓ1 " ! " Keyway + Tapped Type: BS=0; M+3 ≤ BS ≤ ℓ1 [ ! ] If BS = 0, no tapped hole  |

| Alterations | Retaining Ring Groove Dim. | Side Slotted Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Code | SRG | LFC·LTC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spec. | Retaining Ring Groove applicable to the shaft dia. of stepped hole is machined. Dimension Increments 3.5 to 0.5 mm Ordering Code SRG7 Applicable Conditions [ ! ] Applicable only to shaft bore specifications DHL and DHR [ ! ] Standards of retaining ring groove for Z dim. is applied Standard conditions [ ! ] n ≤ J-SRG-m  | ■Retaining Ring Groove Dim.

| Machines slotted holes on the side surface (30°). Dimension Increments LFC, LTC: 1 mm Increments Select M M3, M4, M5, M6 Ordering Code LFC20-M3 Applicable Conditions [ ! ] Applicable to Shape A only Standard Conditions [ ! ] P + C + 4 ≤ LFC (LTC) ≤ G - C- 4  |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Alterations | Side Through Hole | Side Tapped Hole | Side Counterbored | ||||||||||||||||||||

| Code | KFC·KTC | QFC·QTC | ZFC·ZTC | ||||||||||||||||||||

| Spec. | Machines through holes on the side surface. Increments KFC, KTC: 1 mm Increments K: 0.5 mm Increments K selection K3.0 to K6.0 Ordering Code KFC20-K3.5 Applicable Conditions [NG] Not applicable to Shape K Shape A Standard Conditions [ ! ] P + K + 4 ≤ KFC (KTC) ≤ G - K - 4 | Machines tapped holes on the side surface of the gear. Dimension Increments QFC, QTC: 1 mm Increments Select M M3, M4 [ ! ] Tapped hole depth M × 2.0 (When B < M × 2.0, through) Machining datum plane selection is required for Shape B, L-side specification symbol LL, R-side specification symbol RR Applicable Conditions [NG] Not applicable to Shape K Shape A Ordering Code QFC25-M3 Standard Conditions [ ! ] P + M + 4 ≤ QFC (QTC) ≤ G - M - 4 | Machines counterbored holes on the side surface. Dimension Increments ZFC, ZTC: 1 mm Increments Select U U3, U4, U5, U6 Machining datum plane selection required for Shape B, L-side specification symbol LL, R-side specification symbol RR Applicable Conditions [ ! ] Applicable to Standard Type only [NG] Not applicable to Shape K Shape A Ordering Code ZFC20-U3 Standard conditions [ ! ] P + U1 + 3 ≤ ZFC (ZTC) ≤ G - U1- 4 | ||||||||||||||||||||

|  |  |

| ||||||||||||||||||||

| Shape B Standard conditions [ ! ] P + K + 4 ≤ KFC (KTC) ≤ H - K - 4 [ ! ]H+K+4 ≤ KFC (KTC) ≤ G-K-4 | Shape B Ordering Code R-side specification: QFC25-M3-RR, L-side specification: QFC25-M3-LL Standard Conditions [ ! ] P + M + 4 ≤ QFC (QTC) ≤ H - M - 4 [ ! ]H+M+4 ≤ QFC (QTC) ≤ G-M-4 | Shape B Ordering Code R-side specification: ZFC20-U3-RR, L-side specification: ZFC20-U3-LL Standard Conditions [ ! ] P + U1 + 3 ≤ ZFC (ZTC) ≤ H - U1-4 [ ! ]H+U1+4 ≤ ZFC (ZTC) ≤ G-U1-4 | |||||||||||||||||||||

|  |  | |||||||||||||||||||||

| [!] Conditions may vary depending on the shaft bore specs. | [!] Conditions may vary depending on the shaft bore specs. | [!] Conditions may vary depending on the shaft bore specs. | |||||||||||||||||||||

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

More Information

Outline and specifications

General Information - Spur Gears

Selection details of spur gears

- Material: steel, stainless steel, sintered steel, nylon, polyacetal, brass, aluminum, cast iron

- Coatings: burnished, nickel-plated

- Heat treatment: induction hardened

- Shaft diameter tolerances: H7, H8

- Tooth flank clearance: N5, N7, N8, N9, N12

- Module: 0.3, 0.5, 0.75, 0.8, 1, 1.25, 1.5, 2, 2.5, 3, 4, 4.5, 5, 6, 8, 10, 15, 20

- Pressure angle: 20°

- Shaft diameter: 2 mm to 50 mm

- Number of teeth: 8 to 200

- Tooth width: 2 mm to 90 mm

Description/Basics

The spur gears offered are generally machine elements that serve the non-slip transmission of force, movement transmission or movement change. The teeth of the cylinder wheels grip each other during transmission and largely roll over the tooth flanks. The tooth shape of the spur gear is convexly shaped in the shaped tooth system. At the beginning of the intervention, a rolling resistance acts on the tooth flank, which becomes a sliding friction in the course of the rotation.

A combination of gear wheels and rack gears is useful in the construction of rack gear. This allows motor rotary motion or other rotary motion to be converted into linear motion. rack gear boxes are theoretically possible in an endless assembly. Limits here only set the length of the rack gears for the rack gear drive.

Gear wheels with straight gearing are particularly suitable for the construction of gearboxes. The advantage of straight gearing as opposed to helical gears, is the possibility of transmitting a higher torque. It should be noted that with increasing speed within the transmission ratio or reduction, the torque to be transmitted decreases.

When designing spur gear pairs, the ratio of the gear ratio (number of teeth) and the module of the respective gear wheels must be observed.

The backlash is another important factor that must be considered during construction. Reverse play is understood as the result of the play that the change in the direction of rotation of a single gear wheel pair between the teeth. The risk of reverse play can be reduced if either the diameter or the number of teeth of the cogwheel pairing do not deviate too much from one another. If high wear is to be expected due to the pairing of gears, the MISUMI online shop offers gears with a hardened key-type.

For applications with the same rotational direction, it is possible to use an intermediate gear with integrated bearing on a cantilever shaft. The bearing number used can be found under the tab More Information. An overview of tolerances and permissible radial bearing deviations can be found in the following PDF.

In addition to gear wheels, MISUMI also offers suitable rotary shafts for the construction of a transmission. The straight front wheels can be assembled on these and secured with a set screw or machine keys (key with adjusting screw). This PDF provides an overview of the configurable mountings for the shaft rotation and keyway tolerances.

The continuous adjusting of a spur gear can be realized, among other things, by means of a clamping sleeve. The MISUMI online shop offers spur gears with clamping sleeve. Alternatively, we also offer individual keyless bushing that you can customize to your needs.

Application Examples - Spur Gears

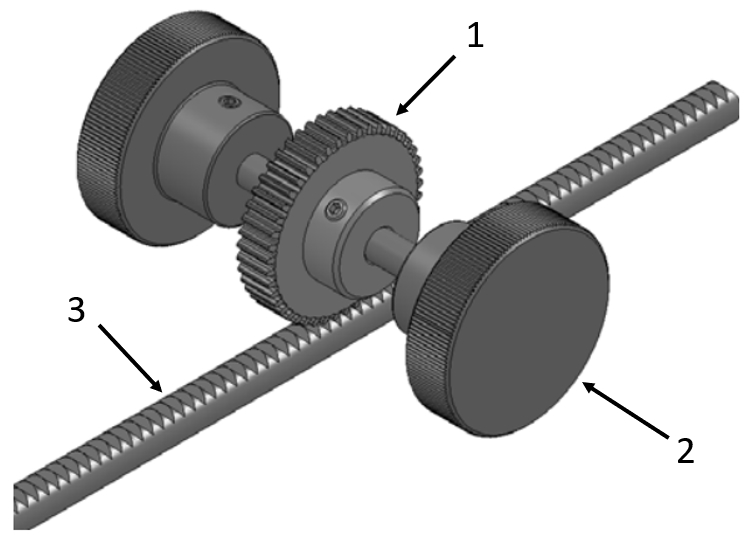

Application example - spur gear with rack gear

(1) Spur gear, (2) Clamping knobs, (3) Rack gear

Application example - spur gear

(1) Spur gear, (2) Workpiece, (3) Rollers

Industrial Applications