Configure

- Stock

- Show stock items only

- Thread Nominal D(φ)

- 10

- 12

- 16

- 20

- Nut O.D. D(φ)

- 20

- 22

- 28

- 32

- Nut Length L1 (or L)(mm)

- 34

- 36.5

- 45

- 52

- Type

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Same-day shipping possible

- Within 5 working days

Lead Screw Nuts / Anti-Basklash Type

Mouse over image to enlarge

Part number:

possible part numbers found.Outline drawing and specifications table

Dimensional Drawing

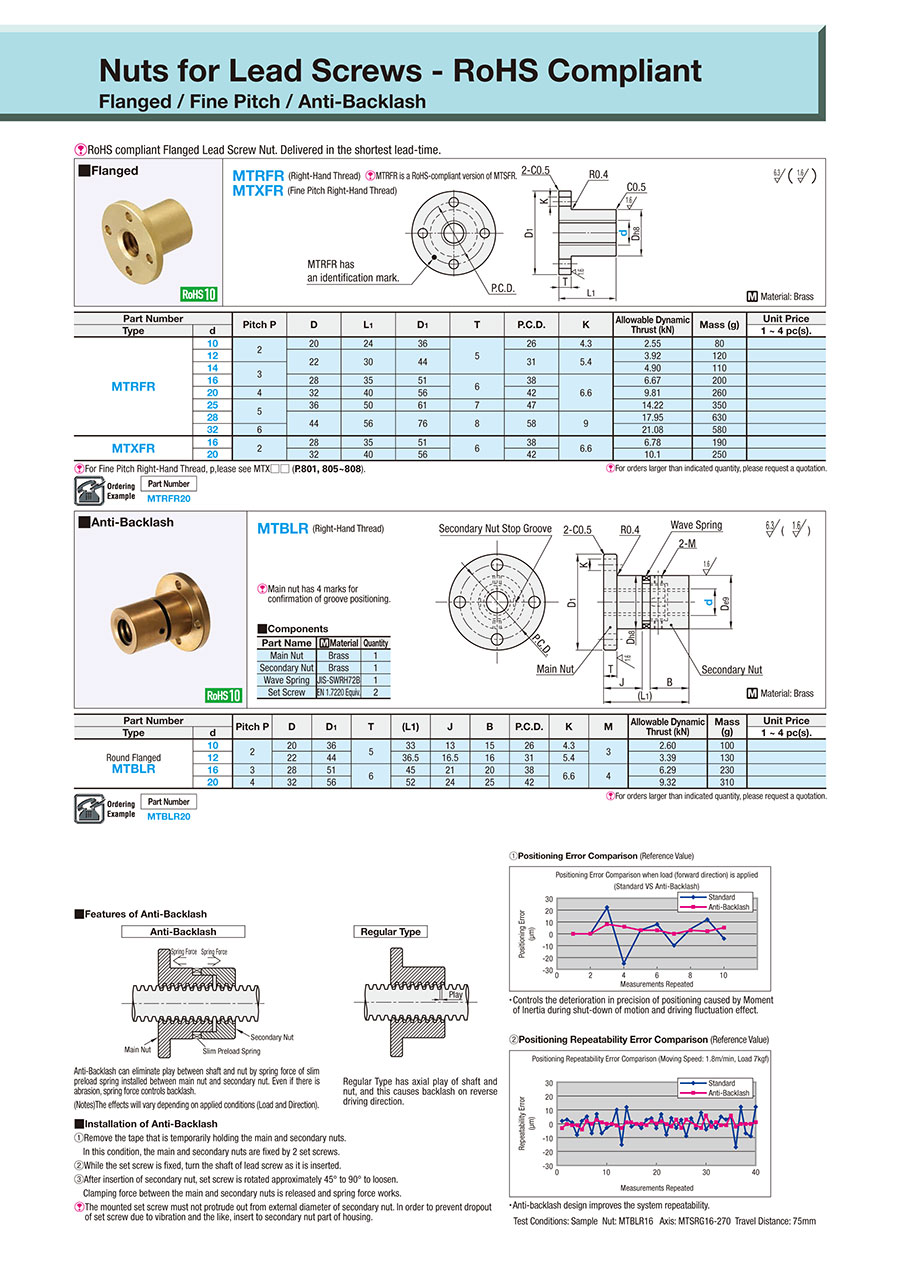

MTBLR (Right-Hand Thread) [ ! ] Main nut has 4 marks for confirmation of groove positioning.

[ ! ] Main nut has 4 marks for confirmation of groove positioning.

h8 Tolerance (D)

Compliant with JIS B 0401

| Over | or less | Tolerance |

| 3 | 6 | 0 -0.018 |

| 6 | 10 | 0 -0.022 |

| 10 | 18 | 0 -0.027 |

| 18 | 30 | 0 -0.033 |

| 30 | 50 | 0 -0.039 |

| 50 | 80 | 0 -0.046 |

Dimensional Tolerances

Without Command

Compliant with JIS B 0405

Class m (intermediate).

Without Command

| Over | or less | Tolerance |

| 0.5 | 3 | ±0.1 |

| 3 | 6 | ±0.1 |

| 6 | 30 | ±0.2 |

| 30 | 120 | ±0.3 |

Class m (intermediate).

■ Components

| Part Name | Material | Qty. |

| Main Nut | Brass | 1 |

| Secondary Nut | Brass | 1 |

| Wave Spring | JIS−SWRH72B | 1 |

| Set Screw | EN 1.7220 Equiv. | 2 |

Material: Brass

Lead Screw Accuracy

The Tr standard has the same standard dimensions as the

old JIS TM standard (abolished).

Dimensional tolerances are regulated for Tr standard.

| Item | Content |

| Standard Chevron | Tr Standard (Old TM Standard) |

| Tolerance and Allowable Dimension | JIS B 0217-1,2 |

| Screw Accuracy (Threaded) | 7e |

| Nut Accuracy (Tapped) | 7H |

| Single Pitch Error | ±0.02 |

| Accumulated Pitch Error | ±0.15/300mm |

old JIS TM standard (abolished).

Dimensional tolerances are regulated for Tr standard.

Standard Chevron Dimensions

| H=1.866P | H1=0.5P | d2=d-0.5P | |

| d1=d-P | D=d | D2=d2 | D1=d1 |

| Male Thread | d:O.D. | d1:Root Dia. | d2:Effective Dia. |

| Female Thread | D:Root Dia. | D1:I.D. | D2:Effective Dia. |

| P:Pitch | H1:Engage Height | ||

Specification Table

| Part Number |

| MTBLR20 |

| Part Number | Pitch P | D | D1 | T | (L1) | J | B | P.C.D. | K | M | Allowable Dynamic Thrust (kN) | Mass (g) | |

| Type | d | ||||||||||||

| Round Flanged MTBLR | 10 | 2 | 20 | 36 | 5 | 33 | 13 | 15 | 26 | 4.3 | 3 | 2.60 | 100 |

| 12 | 22 | 44 | 36.5 | 16.5 | 16 | 31 | 5.4 | 3.39 | 130 | ||||

| 16 | 3 | 28 | 51 | 6 | 45 | 21 | 20 | 38 | 6.6 | 4 | 6.29 | 230 | |

| 20 | 4 | 32 | 56 | 52 | 24 | 25 | 42 | 9.32 | 310 | ||||

For orders larger than indicated quantity, please request a quotation

[ ! ] This product is a single thread screw and therefore the pitch P = lead.

[ ! ] Recommended Grease: Lithium soap-based grease No. 2 (Please wipe off the antirust oil before applying.)

Related Components

Part number list

Number of items

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

119.27 € ( 141.93 € ) | 5 working days |

119.27 € ( 141.93 € ) | Stock item: 1 working dayAvailable for same-day shipping |

122.29 € ( 145.53 € ) | Stock item: 1 working dayAvailable for same-day shipping |

135.76 € ( 161.55 € ) | Stock item: 1 working dayAvailable for same-day shipping |

More Information

Basic information

Outline and specifications

Specifications/Overview

■Features of Anti-Backlash

Anti-Backlash can eliminate play between shaft and nut by spring force of slim preload spring installed between main nut and secondary nut. Even if there is abrasion, spring force controls backlash. (*) The effects will vary depending on applied conditions (Load and Direction). |

Regular Type has axial play of shaft and nut, and this causes backlash on reverse driving direction. |

■Installation of Anti-Backlash

(1) Remove the tape that is temporarily holding the main and secondary nuts.

(In this condition, the main and secondary nuts are fixed by 2 set screws.)

(2) While the set screw is fixed, turn the shaft of lead screw as it is inserted.

(3) After insertion of secondary nut, set screw is rotated approximately 45° to 90° to loosen.

(Clamping force between the main and secondary nuts is released and spring force works.)

[!] The mounted set screw must not protrude out from external diameter of secondary nut. In order to prevent dropout of set screw

due to vibration and the like, insert to secondary nut part of housing.

| (1) Positioning Error Comparison (Reference Value) | (2) Positioning Repeatability Error Comparison (Reference Value) | |

|  | |

| ·Controls the deterioration in precision of positioning caused by Moment of Inertia during shut-down of motion and driving fluctuation effect. | ·Anti-backlash design improves the system repeatability. Test Conditions: Sample Nut: MTBLR16 Shaft: MTSRG16-270 Travel Distance: 75 mm |