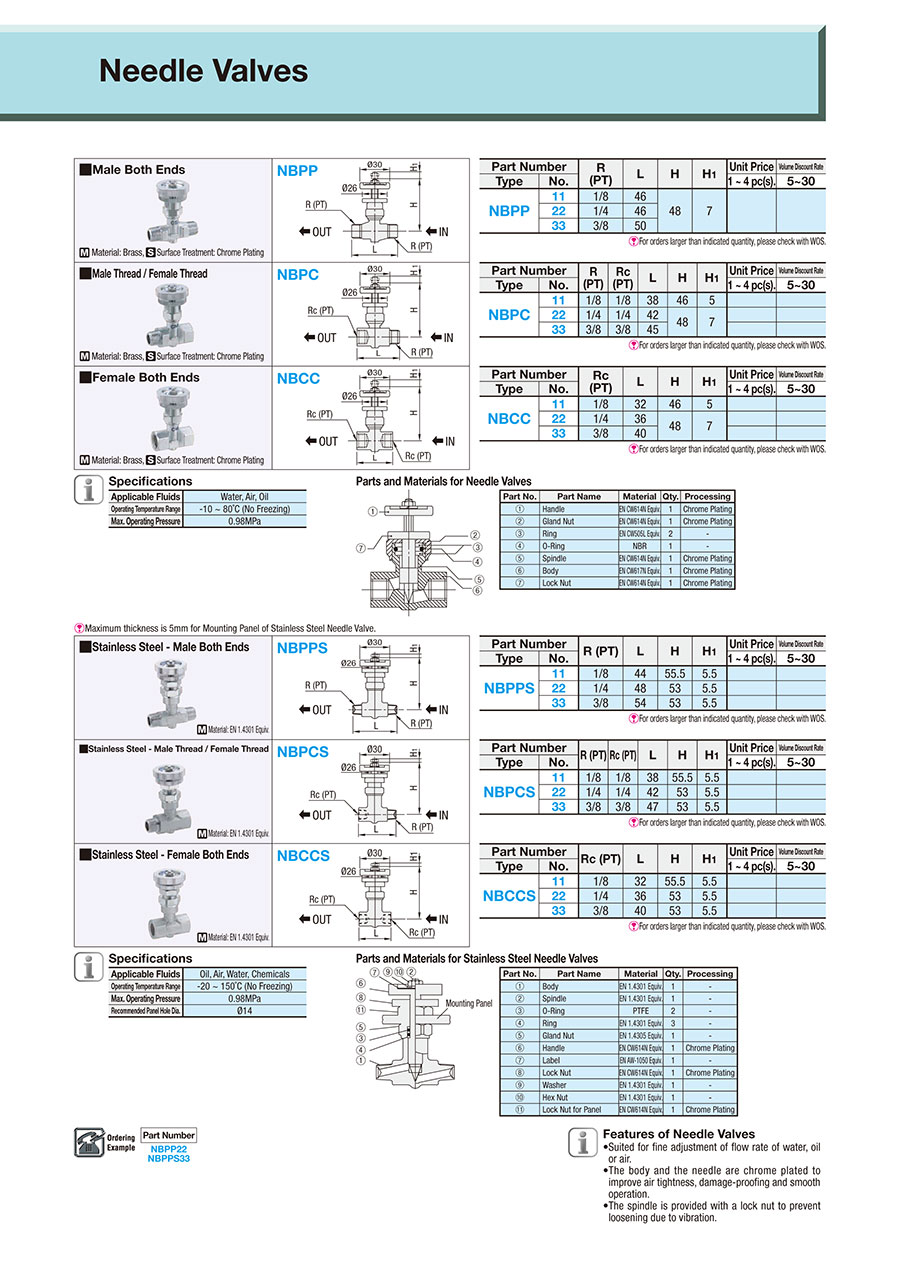

Needle Valve with PT Male Threads / Stainless Steel

Mouse over image to enlarge

Part number:

possible part numbers found.Outline drawing and specifications table

Dimensional Drawing

NBPPS

| Component List | ||||

| No. | Qty. | Part Name | Material | Surface Treatment |

| 01 | 1 | Main Body | EN 1.4301 Equiv. | ― |

| 02 | 1 | Spindle | EN 1.4301 Equiv. | ― |

| 03 | 3 | Back-Up Ring | EN 1.4301 Equiv. | ― |

| 04 | 2 | O-Ring | PTFE | ― |

| 05 | 1 | Gland Nut | EN 1.4305 Equiv. | ― |

| 06 | 1 | Panel nut | EN CW614N Equiv. | Chrome Plating |

| 07 | 1 | Handle lock nut | EN CW614N Equiv. | Chrome Plating |

| 08 | 1 | Lock type handle | EN CW614N Equiv. | Chrome Plating |

| 09 | 1 | Label | EN AW-1070 Equiv. | ― |

| 10 | 1 | Toothed Washer | EN 1.4301 Equiv. | ― |

| 11 | 1 | Nut | EN 1.4301 Equiv. | ― |

[M]Material: EN 1.4301 Equiv.

Specification Table

| Part Number |

| NBPPS33 |

| Part Number | R (PT) | L | H | H1 | d (⌀) Orifice Diameter | |

| Type | No. | |||||

| NBPPS | 11 | 1/8 | 44 | 55.5 | 5.5 | 4 |

| 22 | 1/4 | 48 | 53 | 5.5 | 5 | |

| 33 | 3/8 | 54 | 53 | 5.5 | 5 | |

Technical Information

·Cv Value Curve

The values in the graph are based on the experimental devices and should be used as a reference.

The values in the graph are based on the experimental devices and should be used as a reference.

·Flow Calculation Based on Cv Value

Fluid | Differential Pressure Conditions | ||||

| When P2> P1 2 | When P2≤ P1 2 | ||||

| Liquid | General |  |  | Same as the left | |

| High Viscosity (20 cs or more) |  |  | Same as the left | ||

| Gas | Ambient Temperature |  |  |  |  |

| High Temperature |  |  |  |  | |

| Steam | Saturation |  |  |  |  |

| Overheating |  |  |  |  | |

| Moisture |  |  |  |  | |

| QL(m3/h) | : Liquid Flow Rate |

| Qg(m3/h) | : Gas Flow Rate: Normal Condition (15°C 760 mmHg) |

| Qs(kg/h) | : Steam Flow Rate |

| P1(Mpa abs) | : Primary Absolute Pressure |

| P2(MPA abs) | : Secondary Absolute Pressure |

| K | : Viscosity Correction Factor |

| t(℃) | : Fluid Temperature |

| GL | : Specific Gravity of Liquid (Water = 1) |

| Gg | : Specific Gravity of Gas (Air = 1) |

| S(℃) | : Steam Superheat |

| X | : Steam Dryness (Dry Saturated Steam X = 1) |

·Calculation Example of flow rate based on Cv value (Reference Value)

| If the flow rate calculation conditions are as follows. |

| Valve Size: N□□□22 (1/4) |

| Degree of Opening: 3 turns |

| ΔP = P1 - P2: 0.294 MPa (3 kgf/cm2) (1) |

| Fluid: Water (GL=1)··· (2) |

| The Cv value at 3 turns can be read as = 0.33 from the Cv value curve. ··· (3) |

| Since the fluid is water, the general formula for liquids is used. |

| Transforming this formula into QL = will be the following formula (4). |

Substitute the conditions (1), (2), and (3) into formula (4) and calculate.

[ ! ]The above formula and the results are the reference values.

Values may vary significantly depending on actual environmental conditions, etc.

Values may vary significantly depending on actual environmental conditions, etc.

More Information

Basic information

[Features] Compact needle valve with double male thread. -Allows fine adjustment of the flow rate of water, oil and air.

Outline and specifications

Specifications/Overview

Parts and Materials for Stainless Steel Needle Valves

| Part No. | Part Name | Material | Qty. | Processing |

| (1) | Body | EN 1.4301 Equiv. | 1 | — |

| (2) | Spindle | EN 1.4301 Equiv. | 1 | — |

| (3) | O-Ring | PTFE | 2 | — |

| (4) | Ring | EN 1.4301 Equiv. | 3 | — |

| (5) | Gland Nut | EN 1.4305 Equiv. | 1 | — |

| (6) | Handle | EN CW614N Equiv. | 1 | Chrome Plating |

| (7) | Label | EN AW-1050 Equiv. | 1 | — |

| (8) | Lock Nut | EN CW614N Equiv. | 1 | Chrome Plating |

| (9) | Washer | EN 1.4301 Equiv. | 1 | — |

| (10) | Hex Nut | EN 1.4301 Equiv. | 1 | — |

| (11) | Lock Nut for Panel | EN CW614N Equiv. | 1 | Chrome Plating |

Specifications

| Applicable Fluids | Oil, Air, Water, Chemicals |

| Operating Temp. Range | −20 to 150°C (No Freezing) |

| Max. Operating Pressure | 0.98 MPa |

| Recommended Panel Hole Dia. | ⌀14 |

Features of Needle Valves

·The flow rate of water, oil and air can be finely adjusted.

·The body and the needle are chrome plated to improve air tightness, damage-proofing and smooth operation.

·The spindle is provided with a lock nut to prevent loosening due to vibration.

·The flow rate of water, oil and air can be finely adjusted.

·The body and the needle are chrome plated to improve air tightness, damage-proofing and smooth operation.

·The spindle is provided with a lock nut to prevent loosening due to vibration.