Configure

- Hole Diameter(mm)

- 10

- 12

- 15

- 20

- 25

- 30

- Surface Treatment

- Double Nuts

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 5 working days

Height Adjustment Screw Set for Strut Clamps

Part number:

possible part numbers found.Outline drawing and specifications table

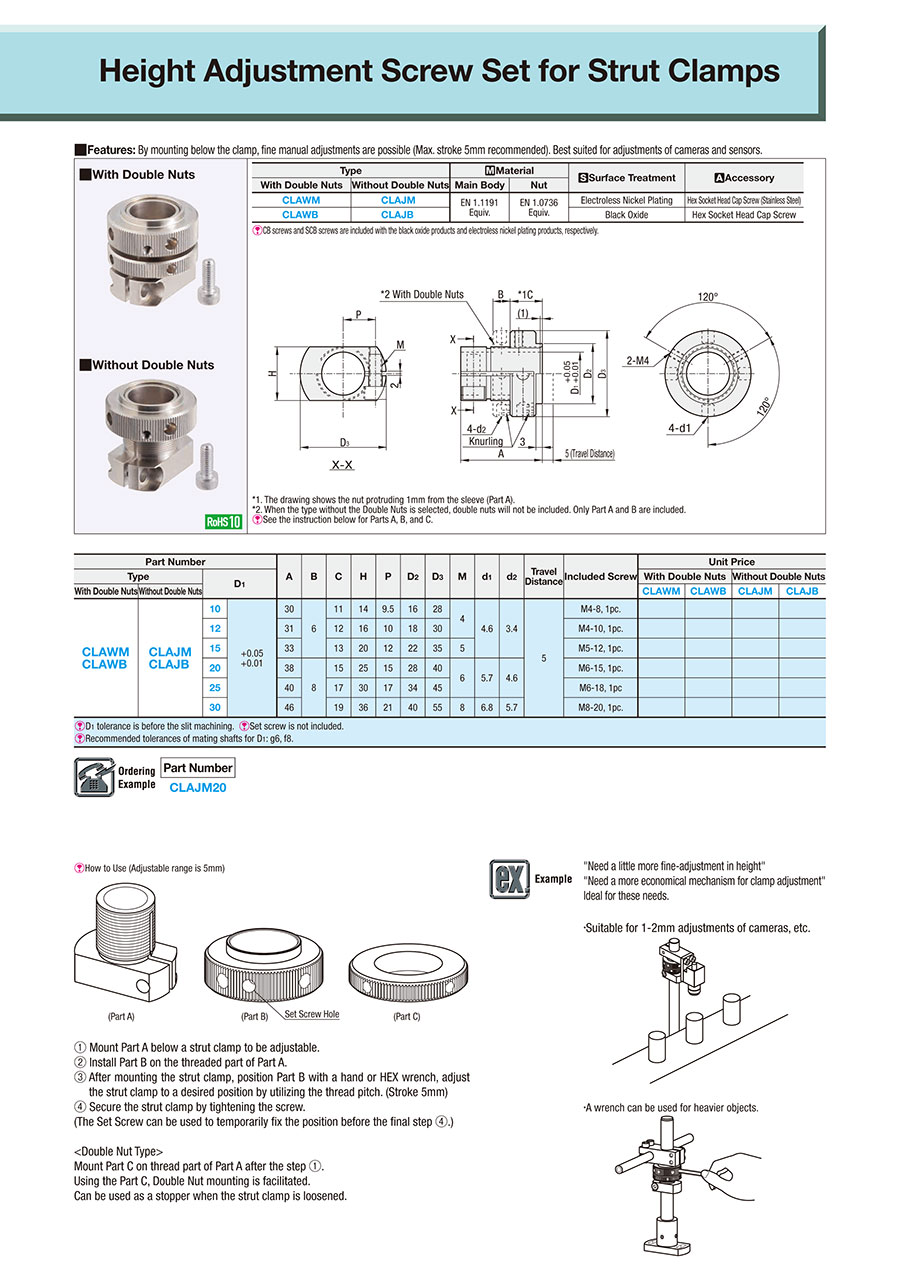

| Type | [M] Material | [S] Surface Treatment | [A] Accessory | ||

| With Double Nuts | Without Double Nuts | Main Body | Nut | ||

| CLAWM | CLAJM | EN 1.1191 Equiv. | EN 1.0736 Equiv. | Electroless Nickel Plating | Hex Socket Head Cap Screw (Stainless Steel) |

| CLAWB | CLAJB | Black Oxide | Hex Socket Head Cap Screw | ||

Specification Table

| Part Number |

| CLAJM20 |

| Part Number | A | B | C | H | P | D2 | D3 | M | d1 | d2 | Travel Distance | Included Screw | |||

| Type | D1 | ||||||||||||||

| With Double Nuts | Without Double Nuts | ||||||||||||||

| CLAWM CLAWB | CLAJM CLAJB | 10 | +0.05 +0.01 | 30 | 6 | 11 | 14 | 9.5 | 16 | 28 | 4 | 4.6 | 3.4 | 5 | M4-8, 1 pc. |

| 12 | 31 | 12 | 16 | 10 | 18 | 30 | M4-10, 1 pc. | ||||||||

| 15 | 33 | 13 | 20 | 12 | 22 | 35 | 5 | M5-12, 1 pc. | |||||||

| 20 | 38 | 8 | 15 | 25 | 15 | 28 | 40 | 6 | 5.7 | 4.6 | M6-15, 1 pc. | ||||

| 25 | 40 | 17 | 30 | 17 | 34 | 45 | M6-18, 1 pc. | ||||||||

| 30 | 46 | 19 | 36 | 21 | 40 | 55 | 8 | 6.8 | 5.7 | M8-20, 1 pc. | |||||

* 2. When "W/O Double Nuts" is selected, double nut is not included.

[!] D1 tolerance is the value measured before slit machining. [!] Set screw is not included. [!] Recommended tolerances of mating shafts for D1: g6, f8.

Part number list

Number of items

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

10.38 € ( 12.35 € ) | 5 working days |

11.64 € ( 13.85 € ) | 5 working days |

13.04 € ( 15.52 € ) | 5 working days |

15.94 € ( 18.97 € ) | 5 working days |

16.58 € ( 19.73 € ) | 5 working days |

21.64 € ( 25.75 € ) | 5 working days |

11.12 € ( 13.23 € ) | 5 working days |

13.41 € ( 15.96 € ) | 5 working days |

14.68 € ( 17.47 € ) | 5 working days |

16.45 € ( 19.58 € ) | 5 working days |

19.87 € ( 23.65 € ) | 5 working days |

23.28 € ( 27.70 € ) | 5 working days |

12.52 € ( 14.90 € ) | 5 working days |

14.55 € ( 17.31 € ) | 5 working days |

15.82 € ( 18.83 € ) | 5 working days |

18.86 € ( 22.44 € ) | 5 working days |

20.00 € ( 23.80 € ) | 5 working days |

25.95 € ( 30.88 € ) | 5 working days |

13.79 € ( 16.41 € ) | 5 working days |

16.19 € ( 19.27 € ) | 5 working days |

17.21 € ( 20.48 € ) | 5 working days |

19.61 € ( 23.34 € ) | 5 working days |

23.66 € ( 28.16 € ) | 5 working days |

27.84 € ( 33.13 € ) | 5 working days |

More Information

Outline and specifications

Specifications/Overview

[!] How to Use (Adjustable range is 5 mm)

(1) Mount Part A below a strut clamp to adjust.

(2) Install Part B on the threaded part of Part A.

(3) After mounting the strut clamp, position Part B with a hand or HEX wrench,

adjust the strut clamp to a desired position by utilizing the thread pitch. (Stroke 5 mm)

(4) Secure the strut clamp by tightening the screw.

(The Set Screw can be used to temporarily fix the position before the final step (4).)

[Double Nut Type]

Mount Part C on thread part of Part A after the step (1).

Using the Part C, Double Nut mounting is facilitated.

Can be used as a stopper when the strut clamp is loosened.

| Part A | Part B | Part C | ||

|  |  |

(2) Install Part B on the threaded part of Part A.

(3) After mounting the strut clamp, position Part B with a hand or HEX wrench,

adjust the strut clamp to a desired position by utilizing the thread pitch. (Stroke 5 mm)

(4) Secure the strut clamp by tightening the screw.

(The Set Screw can be used to temporarily fix the position before the final step (4).)

[Double Nut Type]

Mount Part C on thread part of Part A after the step (1).

Using the Part C, Double Nut mounting is facilitated.

Can be used as a stopper when the strut clamp is loosened.

App. Example

"Fine vertical adjustments are needed." "Economical clamping adjustment mechanism is needed." Best suited for these customer needs.

·Suitable for repositioning cameras, etc. in 1-2 increments.

·A wrench can be used for heavier objects.