Configure

- External Dimension A(mm)[30-200/1mm units]

- External Dimension B(mm)[20-200/1mm units]

- H(mm)[10-100/1mm units]

- Plate Thickness T(mm)

- 1.5

- 1.6

- 2

- 2.3

- 3

- 3.2

- 4

- 4.5

- 6

- V(mm)[15-200/1mm units]

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 7 working days

- Within 9 working days

- Within 19 working days

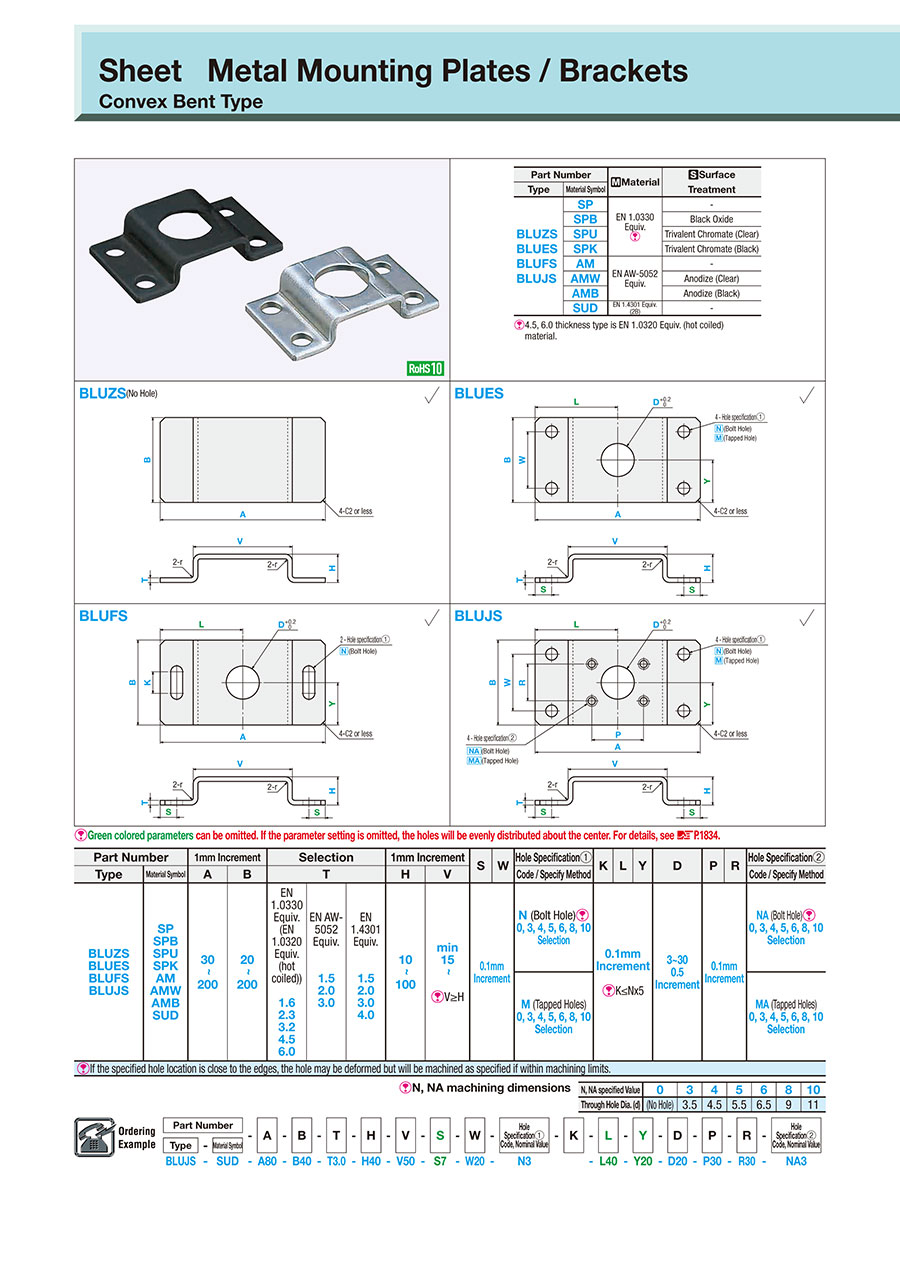

Sheet Metal Mounting Plate / Bracket -Convex Bending Type- BLUES

Part number:

possible part numbers found.Outline drawing and specifications table

BLUES

[ ! ]Green colored parameters can be omitted. If the parameter setting is omitted, the holes will be evenly distributed about the center.

[ ! ]For details on specifications and machining limits, see >> here

[ ! ]For details on specifications and machining limits, see >> here

| ■Hole Type Selection Chart | |||

| Hole Type | Bolt Hole | Tapped Hole (Coarse) | Through Hole with Tolerance |

| Code | N | M | D |

| Shape Diagram | [ ! ]  |  |  |

| [ ! ]For the d dimensions, refer to the "N Machining Dimensions" section below the Specifications Table | |||

| Part Number | [ M ]Material | [ S ]Surface Treatment | |

| Type | Material Symbol | ||

| BLUES | SP | T0.8~3.2 : EN 1.0330 Equiv. T4.5~6.0 : EN 1.0320 Equiv. (hot coiled) | − |

| SPB | Black Oxide | ||

| SPU | Trivalent Chromate (Clear) | ||

| SPK | Trivalent Chromate (Black) | ||

| AM | EN AW−5052 Equiv. | − | |

| AMW | Anodize (Clear) | ||

| AMB | Anodize (Black) | ||

| SUD | EN 1.4301 Equiv. (Passivated 2B) | − | |

Specification Table

| Part Number | - | A | - | B | - | T | - | H | - | V | - | S | - | W | - | Hole Specification① Code, Nominal | - | L | - | Y | - | D | ||

| Type | - | Material Symbol | ||||||||||||||||||||||

| BLUES | - | SP | - | A80 | - | B40 | - | T2.3 | - | H20 | - | V50 | - | S7 | - | W30 | - | N3 | - | L40 | - | Y20 | - | D20 |

| Part Number | 1 mm Increments | Selection | 1 mm Increments | S | W | Hole Specification① | L | Y | D | ||||||

| Type | Material Symbol | A | B | T | H | V | Code / Specify Method | ||||||||

| BLUES | SP SPB SPU SPK | 30 ~ 200 | 20 ~ 200 | 0.8 ・ 1.0 ・ 1.2 ・ 1.6 2.3 ・ 3.2 ・ 4.5 ・ 6.0 | 10 ~ 100 | min 15~ [ ! ]V≥H | 0.1 mm Increments | 0.1 mm Increments | 3~30 (0.5 Increments) | ||||||

| N | M | ||||||||||||||

| (Bolt Hole) | (Tapped Holes) | ||||||||||||||

| AM AMW AMB | 1.0 ・ 1.5 ・ 2.0 ・ 3.0 | 0・3・4・5 | 0・3・4・5 | ||||||||||||

| 6・8・10 | 6・8・10 | ||||||||||||||

| (Selection) | (Selection) | ||||||||||||||

| SUD | 0.8 ・ 1.0 ・ 1.2 ・ 1.5 2.0 ・ 3.0 ・ 4.0 | [ ! ] | [ ! ] | ||||||||||||

| [ ! ]If the specified hole location is close to the edges, the hole may be deformed but will be machined as specified if within machining limits. | |||||||||||||||

[ ! ]N Machining Dimension Table

| N Specified Value | Through Hole Diameter (d) |

| 0 | (No Hole) |

| 3 | 3.5 |

| 4 | 4.5 |

| 5 | 5.5 |

| 6 | 6.5 |

| 8 | 9 |

| 10 | 11 |

[ ! ]Hole Machining Table

| T | N (Bolt Hole) | M (Tapped Holes) |

| 0.8 | 0・3・4・5・6・8・10 | 0 |

| 1.0、1.2 | 0・3 | |

| 1.5、1.6 | 0・3・4 | |

| 2.0、2.3 | 0・3・4・5・6 | |

| 3.0、3.2 | 0・3・4・5・6・8 | |

| 4.0~6.0 | 0・3・4・5・6・8・10 |

Alterations

| Alteration | Corner Cut Change (4 corners) | |

| ||

| Code | CC | |

| Spec. | CC = 1 mm Increments [ ! ]1 ≤ CC ≤ 20 Specifying Method Add CC to the end of a Part Number. Example: ... -CC10 | |

Specifications, Machining Limits

[ ! ]1.See the figure below for tolerances

| [Standard Machined Dimension Tolerances] | ||||||

| Product | Dimension Range (A, H dimension) | 6 or less | Over 6, and 30 or less | Over 30, and 120 or less | Over 120, and 400 or less | |

| Sheet Metal (Bent Products) | Tolerance(a・h) | ±0.3 | ±0.5 | ±0.8 | ±1.2 | |

formed by press working from sheet metal is used.:

[ ! ]2.Burr height 0.1 or less

[ ! ]3.Bend angle tolerance ±1°

[ ! ]4.In case of the thin plates, the tap ridges may be crushed, so please be careful when tightening.

[ ! ]5.There are machining limits for sections b, f, h, g below.

| T | f (Distance between the hole and the bend) | b (Distance between the hole and the end face) | h | g | ||||||

| EN 1.0330 Equiv. EN 1.0320 Equiv. (hot coiled) | EN AW−5052 Equiv. | EN 1.4301 Equiv. | Through Hole | Tapped Hole | Slotted Hole parallel to Hole Bending with Tolerance | |||||

| L Bend | Z, Convex Bend | L Bend | Z, Convex Bend | |||||||

| 0.8 | ー | 0.8 | 2 | 3 | - | - | 3.5 | 1 | 5 | 5 |

| 1.0 | 1.0 | 1.0 | 2 | 3 | 3 | 5.5 | 3.5 | 1 | 5.5 | 5.5 |

| 1.2 | ー | 1.2 | 2 | 3 | 3 | 5.5 | 3.5 | 1 | 5.5 | 5.5 |

| 1.6 | 1.5 | 1.5 | 2 | 3.5 | 3 | 6 | 4 | 1 | 6 | 6 |

| 2.3 | 2.0 | 2.0 | 2 | 4.5 | 3 | 7 | 5 | 1.5 | 7 | 7 |

| 3.2 | 3.0 | 3.0 | 2 | 6.5 | 3 | 9 | 7 | 1.5 | 9 | 9 |

| 4.5 | ー | 4.0 | 3 | 7.5 | 4 | 11 | 8(9) | 2 | 11 | 11 |

| 6.0 | ー | ー | 3 | 14 | 4 | 16 | 15 | 2.5 | 16 | 18 |

[ ! ] Slotted hole f parallel to T4.0 and T4.5 will be (9).

[ ! ] The hole may be deformed if specified at the limit value shown above.

[ ! ]6.There will be some scratches left by press brake. Use r, e, d dimension for reference only.

| T | R after Bending | Brake Scratches | |||

| Position | Depth | ||||

| EN 1.0330 Equiv. EN 1.0320 Equiv. (hot coiled) | EN AW−5052 Equiv. | EN 1.4301 Equiv. | (r) | (e) | (d) |

| 0.8 | ー | 0.8 | 0.8 | 5 | 0.1 |

| 1.0 | 1.0 | 1.0 | 1 | 5 | 0.1 |

| 1.2 | ー | 1.2 | 1.2 | 5 | 0.1 |

| 1.6 | 1.5 | 1.5 | 1.5 | 6 | 0.1 |

| 2.3 | 2.0 | 2.0 | 2.0 | 7.5 | 0.1 |

| 3.2 | 3.0 | 3.0 | 3.0 | 10.5 | 0.2 |

| 4.5 | ー | 4.0 | 4.0 | 13.5 | 0.3 |

| 6.0 | ー | ー | 6.0 | 17 | 0.5 |

[ ! ] If the bend and hole are close to each other, r may be smaller.

[ ! ]7.Bending causes biting and bulging.

[ ! ]8. Since it is manufactured with minimum bending R, there is a possibility of breakage if it is used in an environment where stress is concentrated, such as impact.

■Appearance per Material (Surface Treatment) and Machining Method

| None | Black Oxide | Trivalent Chromate (Clear) | Trivalent Chromate (Black) | |

| SP | SPB | SPU | SPK | |

| EN 1.0330 Equiv. T0.8~3.2 |  |  |  |  |

| EN 1.0320 Equiv. (hot coiled) T4.5~6.0 |  |  |  |  |

| EN 1.0038 Equiv. (Black) T9.0 |  |  |  |  |

| None | Anodize (Clear) | Anodize (Black) | |

| AM | AMW | AMB | |

| EN AW−5052 Equiv. |  |  |  |

| None | |

| SUD | |

| EN 1.4301 Equiv. (Passivated 2B) T0.8~6.0 |  |

| EN 1.4301 Equiv.(No.1) T9.0 |  |

Part number list

Number of items

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 7 working days |

- ( - ) | 19 working days |

- ( - ) | 19 working days |

- ( - ) | 7 working days |

- ( - ) | 9 working days |

- ( - ) | 19 working days |

- ( - ) | 9 working days |

- ( - ) | 7 working days |

More Information

Basic information

Outline and specifications

App. Example