Configure

- Hardness(HRC)

- T Dim. Selection(mm)

- 9

- 12

- 16

- 19

- 20

- 1.L Dim. Specification(mm)[25-70/1mm units]

- 2.H Dim. Selection(mm)

- 10

- 12

- 15

- 20

- 3.W Dim. Specification(mm)[13-48/1mm units]

- 4.A Dim. Specification(mm)[10-100/0.01mm units]

- 5.Mounting Hole (Through Hole)[N]

- 7

- 9

- 6.Mounting Hole (Tapped Hole)[M]

- 6

- 8

- 7.Mounting Hole (Counterbored Hole)[Z]

- 6

- 8

- 8.Mounting Hole (Counterbored Hole)[ZG]

- 6

- 8

- 9.Mounting Hole Dimension[P](mm)[4.5-43.5/0.1mm units]

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 8 working days

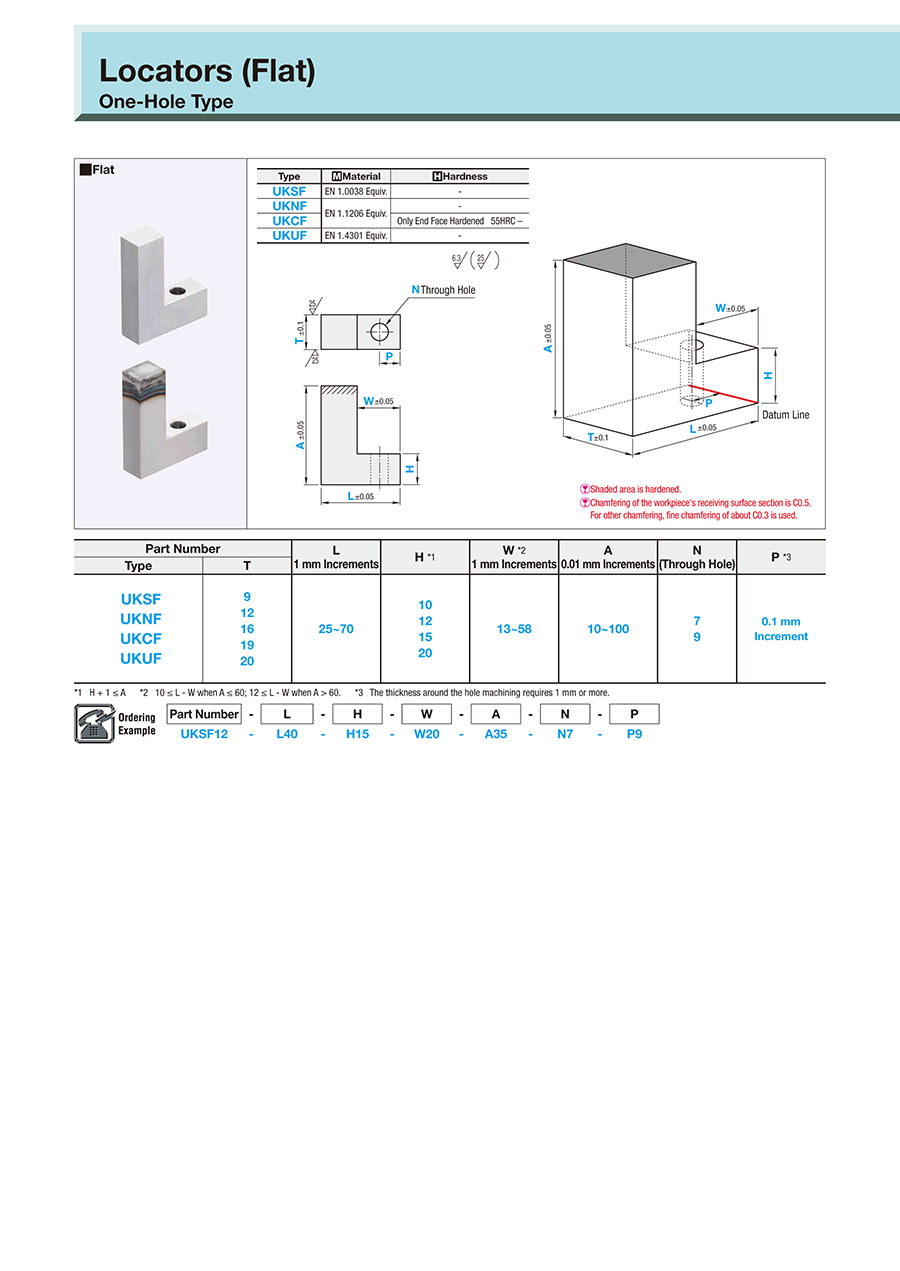

Locators (Flat) One Hole Type

Mouse over image to enlarge

Part number:

possible part numbers found.Outline drawing and specifications table

[!]The shaded area is the hardened area.

[!]The chamfer on the workpiece receiving surface is C0.5. The other chamfers will be slight chamfering of approximately C0.3.

[ ! ] Unless otherwise specified, the dimension tolerance conforms to JIS B 0405 Class m.

| Type | [M] Material | [ H ] Hardness |

| UKSF | EN 1.0038 Equiv. | — |

| UKNF | EN 1.1206 Equiv. | — |

| UKCF | Partially hardened only at the tip 55HRC or higher | |

| UKUF | EN 1.4301 Equiv. | — |

Specification Table

| Part Number | — | L | — | H | — | W | — | A | — | N | — | P |

| UKSF12 | — | L40 | — | H15 | — | W20 | — | A35 | — | N7 | — | P9 |

| Part Number | L Configurable 1 mm Increments | H Selection *1 | W Configurable *2 1 mm Increments | A Specification 0.01 mm Increments | N Selection (Through Hole) | P Configurable *3 | |

| Type | T Selection | ||||||

| UKSF UKNF UKCF UKUF | 9 12 16 19 20 | 25 to 70 | 10 12 15 20 | 13 to 58 | 10 to 100 | 7 9 | Configurable 0.1 mm Unit |

* 1 H+1 ≤ A

* 2 When A ≤ 60, 10 ≤ L - W, and when A > 60, 12 ≤ L - W.

* 3 A minimum wall thickness of 1 mm is required around the hole machining.

Alterations

| Alterations Code | Alteration details | Applicable conditions | Ordering example | |||||||||||||||

| Change hole type | M | Tapped Hole | Change the through hole (N) to a tapped hole. ·M6/M8 Ordering Code: N7→M6 | - | UKSF12-L40-H15-W20-A35-M6-P9 | [ ! ] A minimum wall thickness of 1 mm is required around the holes machining for the alteration described on the left. | ||||||||||||

| Z | Counterbored Hole | Changes Through Hole (N) to Counterbored Hole. ·Z6/Z8 Ordering Code: N9→Z8

| [!]Only applicable to T = 16, 19, 20 | UKSF16-L40-H15-W20-A35-Z6-P9 | ||||||||||||||

| ZG | Counterbored Hole (For spring washer) | Changed Through Hole (N) to Counterbored Hole (for Spring Washer). ·ZG6/ZG8 Ordering Code: N9→ZG8

| [!]Only applicable to T = 16, 19, 20 | UKSF16-L40-H15-W20-A35-ZG6-P9 | ||||||||||||||

| Add Hole Type | MB | Tapped Hole | Tapped Hole on the bottom of the receiving surface. ·MB6/MB8 ·J dimension = 0.1 mm Increments Ordering Code: MB6-J33 | [NG] Tapped holes cannot be added within the W dimension range. [NG] Combination with LPH/K is not possible. | UKSF12-L40-H15-W20-A35-N7-P9-MB6-J33 | |||||||||||||

| K | Add dowel hole | Dowel hole on the bottom of the receiver. ·K6/K8 ·E dimension = 0.1 mm Increments Ordering Code: K6-E33 | [NG] Tapped holes cannot be added within the W dimension range. [NG] Combination with LPH/MB is not possible. | UKSF12-L40-H15-W20-A35-N7-P9-K6-E33 | ||||||||||||||

| CA/ CB/ CC/ CD/ CT | Chamfer | Chamfer the receiving surface or bottom surface. ·Chamfer Location: Please select the required location from CA/CB/CC/CD/CT. ·Chamfer width specified: Specify 1, 3, 5 or 10. Ordering Code: CA5 | - | UKSF12-L40-H15-W20-A35-N7-P9-CA3-CC3 | ||||||||||||||

| LPH | Through hole machining for locating pin | A through hole for locating pin has been added to the shaded area of the diagram, which includes the receiving surface of the workpiece. ·LPH = ø6 to ø14 0.5 mm Increments ·X dimension = 0.1 mm increments Ordering Code: LPH7-X33 | [ ! ] If the height of the receiving surface is greater than (ø × 8), misalignment within 0.2 mm will occur. [NG] Combination with MB/K is not possible. | UKSF12-L40-H15-W20-A35-N7-P9-LPH7-X33 | ||||||||||||||

| ZKC | Height accuracy | Changed the A Dimension tolerance A to ±0.03. Ordering Code: ZKC | - | UKSF12-L40-H15-W20-A35-N7-P9-ZKC | ||||||||||||||

| VK | Marking (V Groove) | Add a marking line V groove to the receiving surface. ·V groove is 0.5 mm wide and 0.2 mm deep ·They are evenly spaced across the length/width of the receiving surface. Ordering Code: VK | [ ! ] The width tolerance is ±0.2 and the depth tolerance is ±0.1. | UKSF12-L40-H15-W20-A35-N7-P9-VK | ||||||||||||||

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

More Information

Basic information

[Features] Shape of mounting surface: flat, fixing holes: This is a 1-circle mounting block.