- Metal Part Outer Diameter D

- 20

- 30

- 40

- 50

- Material

- Steel

- Steel

- Aluminum

- Aluminum Alloy

- Stainless Steel

- SUS304

- Internal Diameter d

- 6

- 8

- 10

- 12

- 15

- 20

- 25

- Properties / applications

- Surface Treatment

- Groove Shape

- Overall Length L(㎜)[50-500/1㎜ units]

- Groove Pitch(㎜)[10-470/1㎜ units]

- Number of Grooves(Groove)

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- Belt Dia.(ø)

- 2

- 3

- 4

- 5

- 6

- CAD

- 3D

- Est. shipping days

- All

- Within 9 working days

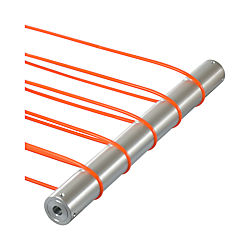

Grooved Roller for Round Belt (Center-Symmetrical Pitch Type) Set Screw Type

Part number:

possible part numbers found.Outline drawing and specifications table

|

|

|

| ||||||||||||||||||

| Type | Material | Surface Treatment | |||

| U Groove | Wide Groove | Trapezoid Groove | Roller | Press Fit Bushing | |

| MRCUA | MRCWA | MRCDA | 5000 Series Aluminum Alloy | 5000 Series Aluminum Alloy | Clear Anodize |

| MRCUS | MRCWS | MRCDS | EN 1.4301 Equiv. | EN 1.4301 Equiv. | — |

| MRCUM | MRCWM | MRCDM | Carbon Steel | EN 1.1191 Equiv. | Electroless Nickel Plating |

Specification Table

| Part Number | — | d | — | L | — | P | — | N | — | A |

| MRCUA30 | — | 10 | — | 300 | — | P50 | — | N5 | — | A3 |

| Part Number | dH9 | Overall Length L 1 mm Increments | Groove Pitch P 1 mm Increments | Number of Grooves N | Belt Dia. (ø) A | L1 | F | d1 | D1 | M | |||||

| Type | D | ||||||||||||||

| Aluminum Alloy | EN 1.4301 Equiv. | Carbon Steel | |||||||||||||

| U Groove MRCUA MRCUS MRCUM | Wide Groove MRCWA MRCWS MRCWM | Trapezoid Groove MRCDA MRCDS MRCDM | 20 | 6 | 50 to 200 | P ≥ 10 However , F ≥ 15 | N ≥ 2 However , F ≥ 15 Number of Grooves: Max. 30 | 2·3 | L1 = P× (N-1) | F ≥ 15 F = (L-L1)/2 | 11 | 13 | 12 | 15 | M4 |

| 8 | |||||||||||||||

| 30 | 8 | 50 to 300 | 2·3·4 | 15 | 18 | 15.8 | 22 | ||||||||

| 10 | |||||||||||||||

| 12 | |||||||||||||||

| 40 | 12 | 50 to 500 | 2·3·4·5 | 17 | 22 | 22.7 | 33 | ||||||||

| 15 | M5 | ||||||||||||||

| 20 | 22 | M6 | |||||||||||||

| 50 | 15 | 2·3·4·5·6 | 17 | 28 | 30 | 40 | M5 | ||||||||

| 20 | 27 | M6 | |||||||||||||

| 25 | |||||||||||||||

Number of grooves N is 2 ≤ N ≤ ([L - 2 × F]/10 [minimum pitch distance]) + 1

The bushings at each end are press fit.

A shaft tolerance of g6 is recommended.

Set screws are not included.

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

- ( - ) | 9 working days |

More Information

Basic information

Grooved rollers for round belts, with set screws.

Multiple grooves can be machined on one roller, reducing the number of parts.

Roller length and groove position are configurable in 1‑mm increments. The number of grooves can be freely selected.

The groove pitch is symmetrical to the center. Ideal when groove pitch is uniform.

Three types available with different groove shapes.

◆ U Groove: Standard; W Groove: Inclined belts, etc. (no recommended angle); Trapezoid Groove: Belt slip reduction

♦ Material: Aluminum Alloy, Stainless Steel (EN 1.4301 Equiv.), Carbon Steel

♦ Applicable Round Belt Dia.: ø3 to 6

Related ProductsClick here for the Bearing Type.

Bearing Type

Click here for the Both Ends Pitch Configurable TypeBearing TypeSet Screw Type

Outline and specifications

App. Example