- Rubber Group Material

- Nitrile Rubber

- Nitrile Rubber

- Silicone Rubber

- Silicone Rubber

- Color

- Black

- White

- White

- Width X

- 4

- 5

- 6

- 8

- Length Y

- 10

- 20

- 30

- Type

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 11 working days

Vacuum Pad Oval Type VPC Barb Fitting Type

Part number:

possible part numbers found.Product information

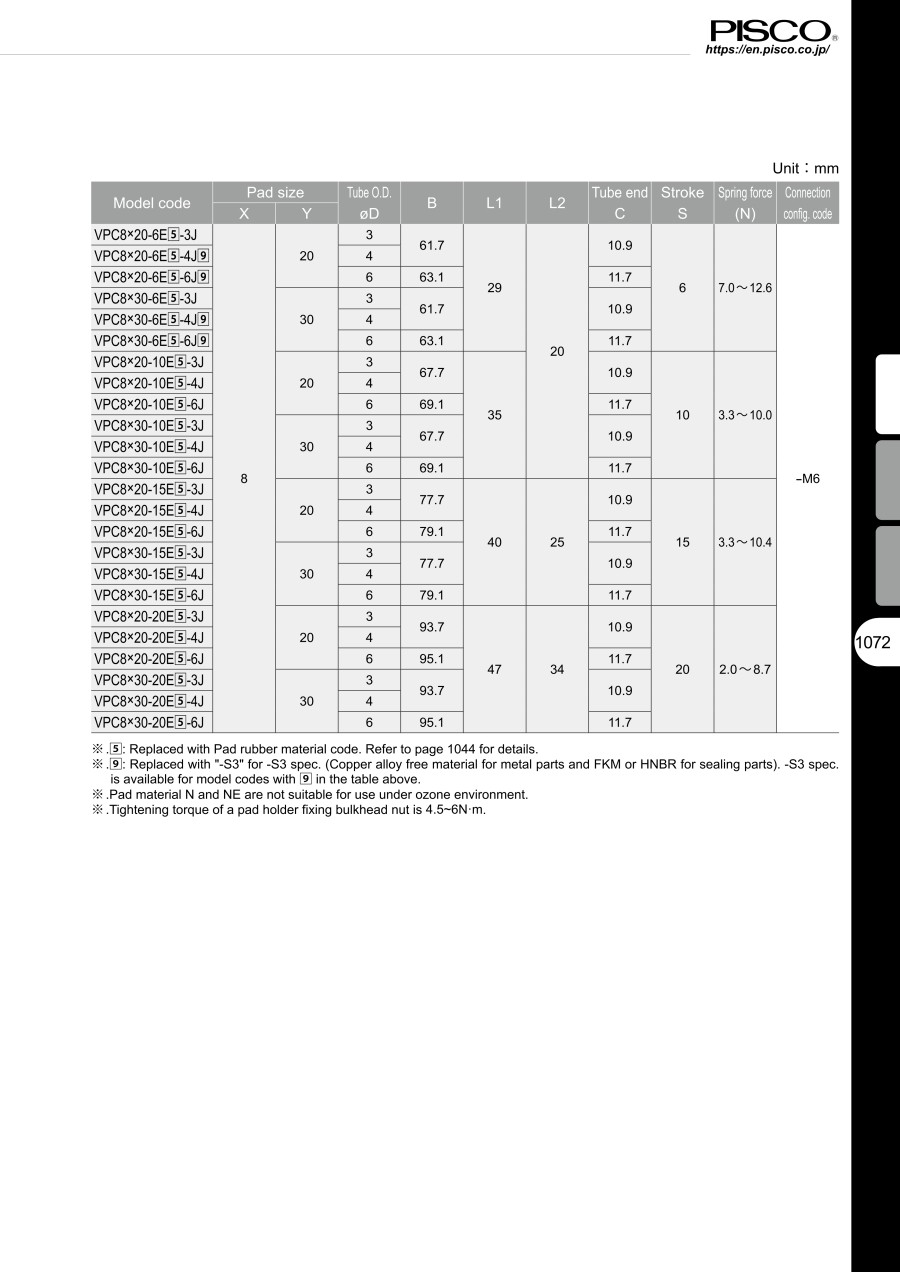

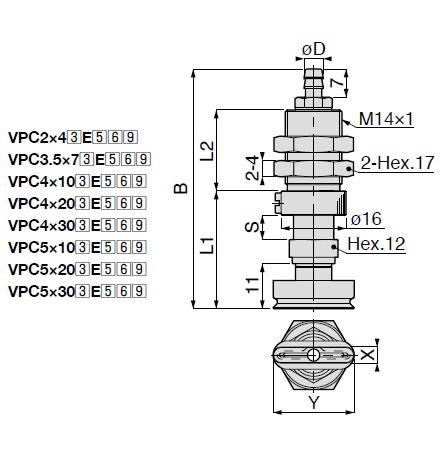

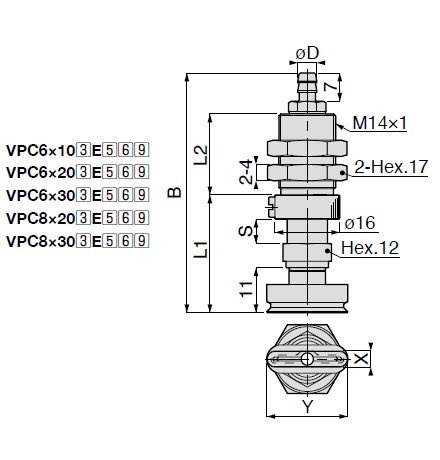

Dimensions

Standard table

| Model code | Pad size X | Pad size Y | Tube I.D. øD | B | L1 | L2 | Stroke S | Spring force (N) | Connection config. code |

|---|---|---|---|---|---|---|---|---|---|

| VPC4×10-6E[5]-6B[9] | 4 | 10 | 4 | 59.1 | 29 | 20 | 6 | 7.0~12.6 | -M6 |

| VPC4×20-6E[5]-6B[9] | 20 | ||||||||

| VPC4×30-6E[5]-6B[9] | 30 | ||||||||

| VPC4×10-10E[5]-6B | 10 | 65.1 | 35 | 10 | 3.3~10.0 | ||||

| VPC4×20-10E[5]-6B | 20 | ||||||||

| VPC4×30-10E[5]-6B | 30 | ||||||||

| VPC4×10-15E[5]-6B | 10 | 75.1 | 40 | 25 | 15 | 3.3~10.4 | |||

| VPC4×20-15E[5]-6B | 20 | ||||||||

| VPC4×30-15E[5]-6B | 30 | ||||||||

| VPC4×10-20E[5]-6B | 10 | 91.1 | 47 | 34 | 20 | 2.0~8.7 | |||

| VPC4×20-20E[5]-6B | 20 | ||||||||

| VPC4×30-20E[5]-6B | 30 | ||||||||

| VPC5×10-6E[5]-6B[9] | 5 | 10 | 59.1 | 29 | 20 | 6 | 7.0~12.6 | ||

| VPC5×20-6E[5]-6B[9] | 20 | ||||||||

| VPC5×30-6E[5]-6B[9] | 30 | ||||||||

| VPC5×10-10E[5]-6B | 10 | 65.1 | 35 | 10 | 3.3~10.0 | ||||

| VPC5×20-10E[5]-6B | 20 | ||||||||

| VPC5×30-10E[5]-6B | 30 | ||||||||

| VPC5×10-15E[5]-6B | 10 | 75.1 | 40 | 25 | 15 | 3.3~10.4 | |||

| VPC5×20-15E[5]-6B | 20 | ||||||||

| VPC5×30-15E[5]-6B | 30 | ||||||||

| VPC5×10-20E[5]-6B | 10 | 91.1 | 47 | 34 | 20 | 2.0~8.7 | |||

| VPC5×20-20E[5]-6B | 20 | ||||||||

| VPC5×30-20E[5]-6B | 30 | ||||||||

| VPC6×10-6E[5]-6B[9] | 6 | 10 | 59.1 | 29 | 20 | 6 | 7.0~12.6 | ||

| VPC6×20-6E[5]-6B[9] | 20 | ||||||||

| VPC6×30-6E[5]-6B[9] | 30 | ||||||||

| VPC6×10-10E[5]-6B | 10 | 65.1 | 35 | 20 | 10 | 3.3~10.0 | |||

| VPC6×20-10E[5]-6B | 20 | ||||||||

| VPC6×30-10E[5]-6B | 30 | ||||||||

| VPC6×10-15E[5]-6B | 10 | 75.1 | 40 | 25 | 15 | 3.3~10.4 | |||

| VPC6×20-15E[5]-6B | 20 | ||||||||

| VPC6×30-15E[5]-6B | 30 | ||||||||

| VPC6×10-20E[5]-6B | 10 | 91.1 | 47 | 34 | 20 | 2.0~8.7 | |||

| VPC6×20-20E[5]-6B | 20 | ||||||||

| VPC6×30-20E[5]-6B | 30 | ||||||||

| VPC8×20-6E[5]-6B[9] | 8 | 20 | 59.1 | 29 | 20 | 6 | 7.0~12.6 | ||

| VPC8×30-6E[5]-6B[9] | 30 | ||||||||

| VPC8×20-10E[5]-6B | 20 | 65.1 | 35 | 20 | 10 | 3.3~10.0 | |||

| VPC8×30-10E[5]-6B | 30 | ||||||||

| VPC8×20-15E[5]-6B | 20 | 75.1 | 40 | 25 | 15 | 3.3~10.4 | |||

| VPC8×30-15E[5]-6B | 30 | ||||||||

| VPC8×20-20E[5]-6B | 20 | 91.1 | 47 | 34 | 20 | 2.0~8.7 | |||

| VPC8×30-20E[5]-6B | 30 |

Units: mm

*[5]: Replaced with Pad rubber material code. Refer to the catalog for details.

*[9]: Replaced with "-S3" for -S3 spec. (Copper alloy free material for metal parts and FKM or HNBR for sealing parts).

*Pad material N and NE are not suitable for use under ozone environment.

*Tightening torque of a pad holder fixing bulkhead nut is 4.5~6 N·m.

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

25.89 € ( 30.81 € ) | 11 working days |

28.20 € ( 33.56 € ) | 11 working days |

26.35 € ( 31.36 € ) | 11 working days |

28.68 € ( 34.13 € ) | 11 working days |

26.81 € ( 31.90 € ) | 11 working days |

29.15 € ( 34.69 € ) | 11 working days |

25.89 € ( 30.81 € ) | 11 working days |

28.20 € ( 33.56 € ) | 11 working days |

26.35 € ( 31.36 € ) | 11 working days |

28.68 € ( 34.13 € ) | 11 working days |

26.81 € ( 31.90 € ) | 11 working days |

29.15 € ( 34.69 € ) | 11 working days |

25.89 € ( 30.81 € ) | 11 working days |

28.20 € ( 33.56 € ) | 11 working days |

26.35 € ( 31.36 € ) | 11 working days |

28.68 € ( 34.13 € ) | 11 working days |

26.81 € ( 31.90 € ) | 11 working days |

29.15 € ( 34.69 € ) | 11 working days |

26.35 € ( 31.36 € ) | 11 working days |

28.68 € ( 34.13 € ) | 11 working days |

26.81 € ( 31.90 € ) | 11 working days |

29.15 € ( 34.69 € ) | 11 working days |

More Information

Basic information

* The CAD data for this series is being revised. This will be available as soon as modifications are complete.

[Features]

· Optimal for conveying long workpieces, such as circuit boards and semiconductors.

· A wide range of pad sizes, pad materials, and holder shapes are available.

· Downsizes holders (A and B types) for existing vacuum pads to save space.

· As is conventionally done, you can change the pad section without removing the holder from the equipment.

· Moreover, it is compatible with the optional fall prevention valve and pad direct attachment type filter.

· Pad holders have been added to applications with "copper-based metal not used" and "reduce ozone concentrations” requirements.

· Copper-based metal is not used for metal parts. HNBR is used for sealing rubber material.