Vacuum Pad Nonskid VPA Barb Fitting Type

Part number:

possible part numbers found.Product information

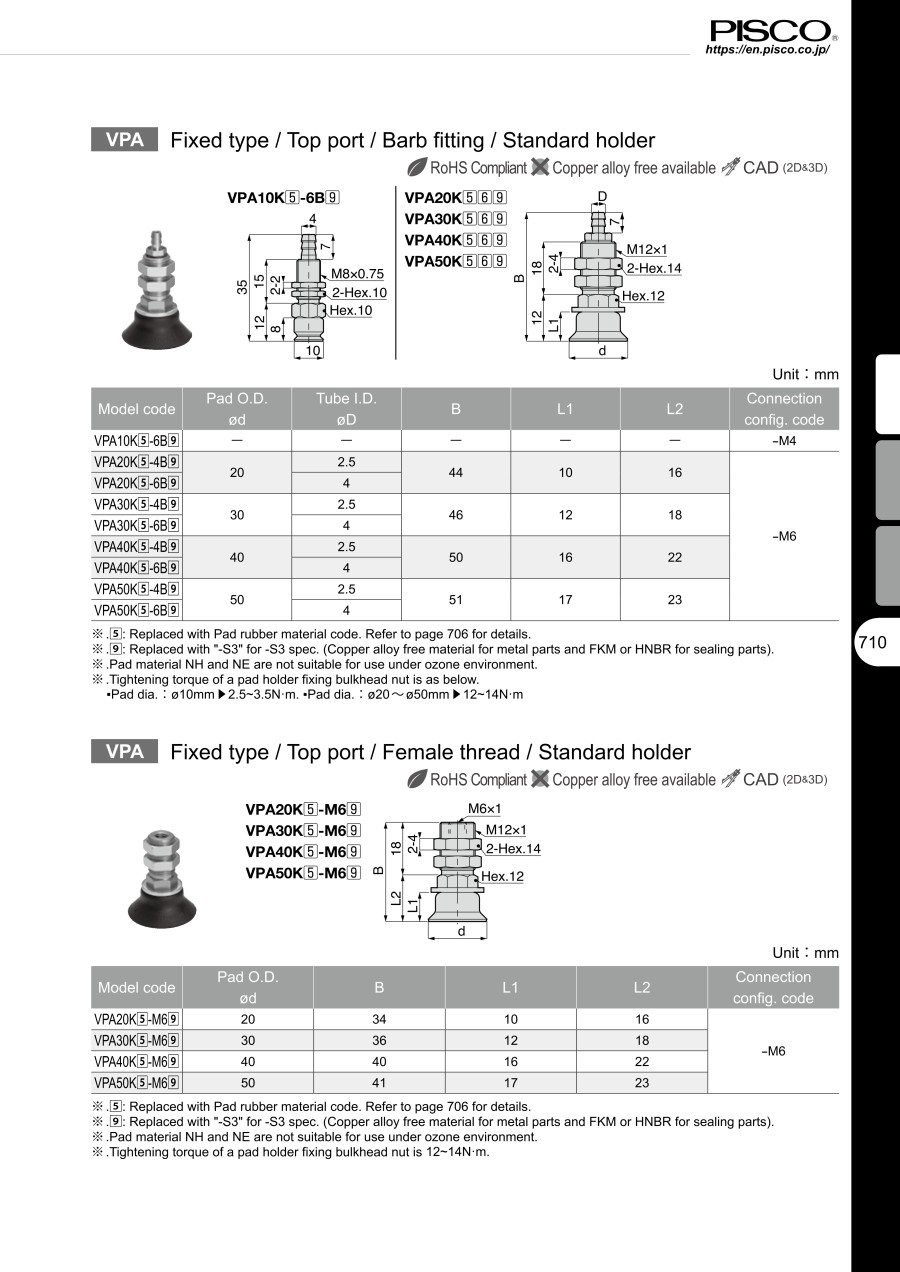

Dimensions

Standard table

| Model code | Pad O.D. ød | Tube I.D. øD | B | L1 | L2 | Connection config. code |

|---|---|---|---|---|---|---|

| VPA10K[5]-6B[9] | 10 | 4 | 35 | 8 | 12 | -M4 |

| VPA20K[5]-6B[9] | 20 | 4 | 44 | 10 | 16 | -M6 |

| VPA30K[5]-6B[9] | 30 | 4 | 46 | 12 | 18 | -M6 |

| VPA40K[5]-6B[9] | 40 | 4 | 50 | 16 | 22 | -M6 |

| VPA50K[5]-6B[9] | 50 | 4 | 51 | 17 | 23 | -M6 |

Units: mm

*[5]: Replaced with Pad rubber material code. Refer to the catalog for details.

*[9]: Replaced with "-S3" for -S3 spec. (Copper alloy free material for metal parts and FKM or HNBR for sealing parts).

*Pad material NH and NE are not suitable for use under ozone environment.

*Tightening torque of a pad holder fixing bulkhead nut is as below.

▪Pad dia.: ø10 mm ▶ 2.5~3.5 N·m.

▪Pad dia.: ø20~ø50mm▶12~14 N·m

Part number list

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

15.59 € ( 18.55 € ) | 11 working days |

16.20 € ( 19.28 € ) | 11 working days |

16.67 € ( 19.84 € ) | 11 working days |

18.52 € ( 22.04 € ) | 11 working days |

20.65 € ( 24.57 € ) | 11 working days |

More Information

Basic information

· Optimally suited for transporting oil-applied work, such as stamped parts, etc. *The CAD data for this Series is being revised. This data will be made available as soon as the modifications have been completed.

[Features]

· Work-slip during transportation is prevented by an innovative pad shape.

· The durability of the pads in oily environments has been improved by utilizing oil-resistant NBR.

· We offer this fitting in a wide range of pad sizes, pad materials, and holder shapes.

· The holders (A and B types) have been downsized for existing vacuum pads making it possible to save space.

· The pad can be changed in the normal way without detaching the holder from the equipment.

· This fitting is also compatible with the optional fall prevention valve and the directly attachable type pad filters.

· Pad holders have been added that are suitable for fields that require the use of non-copper based metals and measures against low-concentration ozone.

· No copper-based metals are used in the metal component materials. HNBR is utilized for the rubber sealing material.