- R Size(mm)

- 0.5

- 1

- 1.5

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- 12.5

- Flute Length (ℓ)(mm)

- 2

- 3

- 4

- 6

- 8

- 10

- 13

- 15

- 20

- 25

- 30

[5-30/1mm units] - Overall Length (L)(mm)

- 70

- 80

- 100

- 140

- 160

- 180

- 200

- 220

- 250

- 280

- Length Under Neck (ℓ1)(mm)[15-80/1mm units]

- Shank Diameter (d)(mm)

- 3

- 4

- 6

- 8

- 10

- 12

- 16

- 20

- 25

- R Precision(μm)

- Inventory Classification

- Est. shipping days

- All

- Within 5 working days

- Within 7 working days

- Within 8 working days

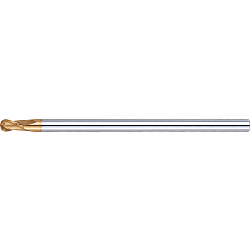

TSC series carbide ball end mill, 2-flute / short, long shank model

Mouse over image to enlarge

Part number:

possible part numbers found.Outline drawing

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

85.91 € ( 102.23 € ) | 5 working days |

90.67 € ( 107.90 € ) | 5 working days |

66.12 € ( 78.68 € ) | 5 working days |

69.54 € ( 82.75 € ) | 5 working days |

105.49 € ( 125.53 € ) | 5 working days |

95.54 € ( 113.69 € ) | 5 working days |

137.64 € ( 163.79 € ) | 5 working days |

120.72 € ( 143.66 € ) | 5 working days |

149.45 € ( 177.85 € ) | 5 working days |

246.63 € ( 293.49 € ) | 5 working days |

394.62 € ( 469.60 € ) | 5 working days |

645.67 € ( 768.35 € ) | 5 working days |

More Information

Basic information

[Features]

-Long shank, ideal for deep cavity milling

It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, range of services, prices, etc.

Specifications and price

Specifications

| Model Number | Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Shank Diameter d |

Figure | |

| Tip R |

||||||

| TSC-LS-BEM2S | 0.5 | 2 | 1 | 70 | 3 | 1 |

| 1 | 3 | 2 | 70 | 3 | 1 | |

| 1.5 | 4 | 3 | 80 | 3 | 2 | |

| 2 | 6 | 4 | 100 | 4 | 2 | |

| 2.5 | 8 | 5 | 100 | 6 | 1 | |

| 3 | 10 | 6 | 140 | 6 | 2 | |

| 4 | 13 | 8 | 160 | 8 | 2 | |

| 5 | 15 | 10 | 180 | 10 | 2 | |

| 6 | 15 | 12 | 200 | 12 | 2 | |

| 8 | 20 | 16 | 220 | 16 | 2 | |

| 10 | 25 | 20 | 250 | 20 | 2 | |

| 12.5 | 30 | 25 | 280 | 25 | 2 |

For Cutting Conditions, Refer to >>Click here.

Features and usage examples

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● The long shank model is ideal for machining deep grooves.

[ ! ]The following additional processing services are available for the products on this page.