- R Size(mm)

- 1

- 1.5

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- Flute Length (ℓ)(mm)

- 3

- 4

- 6

- 8

- 10

- 13

- 15

- 20

- 25

[5-20/1mm units] - Overall Length (L)(mm)

- 50

- 60

- 80

- 150

- Length Under Neck (ℓ1)(mm)[15-75/1mm units]

- Shank Diameter (d)(mm)

- 6

- 8

- 10

- 12

- 16

- 20

- Inventory Classification

- Est. shipping days

- All

- Within 5 working days

- Within 7 working days

- Within 8 working days

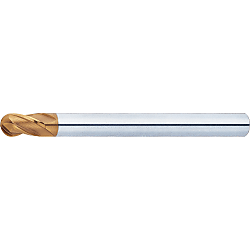

TSC series carbide ball end mill, short model

Mouse over image to enlarge

Part number:

possible part numbers found.Outline drawing

Part number list

| Part number |

|---|

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 8 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

- ( - ) | 7 working days |

54.94 € ( 65.38 € ) | 5 working days |

38.27 € ( 45.54 € ) | 5 working days |

39.98 € ( 47.58 € ) | 5 working days |

46.68 € ( 55.55 € ) | 5 working days |

41.94 € ( 49.91 € ) | 5 working days |

68.20 € ( 81.16 € ) | 5 working days |

88.18 € ( 104.93 € ) | 5 working days |

111.69 € ( 132.91 € ) | 5 working days |

317.59 € ( 377.93 € ) | 5 working days |

427.20 € ( 508.37 € ) | 5 working days |

More Information

Basic information

[Features]

-The surface of the workpiece is very good after machining.

-It has a coating with high oxidation resistance and high hardness, and achieves long service life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, performance range, prices, etc.

Specifications and price

Specifications

| Model Number | Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Shank Diameter d |

Figure | |

| Tip R |

||||||

| TSC-BEM4S | 1 | 3 | 2 | 50 | 6 | 1 |

| 1.5 | 4 | 3 | 50 | 6 | 1 | |

| 2 | 6 | 4 | 50 | 6 | 1 | |

| 2.5 | 8 | 5 | 50 | 6 | 1 | |

| 3 | 10 | 6 | 60 | 6 | 2 | |

| 4 | 13 | 8 | 60 | 8 | 2 | |

| 5 | 15 | 10 | 80 | 10 | 2 | |

| 6 | 15 | 12 | 80 | 12 | 2 | |

| 8 | 20 | 16 | 150 | 16 | 2 | |

| 10 | 25 | 20 | 150 | 20 | 2 |

For Cutting Conditions, Refer to >>Click here.

Features and usage examples

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● Delivers a finish with a very good working surface roughness after machining.

[ ! ]The following additional processing services are available for the products on this page.