Configure

- Extrusion Type

- Surface Treatment

- L Dimension Fixed, Specified

- Overall Length L (Effective Length)(mm)

- 4000

- Overall Length L(mm)[50-4000/0.5mm units]

- CAD

- 2D

- 3D

- Est. shipping days

- All

- Within 5 working days

8-50 Series / slot width 10 / 50x100mm

Caution

- Cutting is free for this product. Please specify the length you prefer.

Part number:

possible part numbers found.Outline drawing and specifications table

Dimensional Drawing

| NEFS (Economy Type) | HFS (Standard Type) | GNFS (High Rigidity Type) | ||

| EFS (Standard Type) | GFS (High Rigidity Type) | |||

|  |  |

| 8-45 Series | |

| ||

| * No tolerance is specified for fixed length extrusions | ||

Product Specifications

Slot Details (Common to HFS, CAF, GNFS, NFSL Series)

Slot Details (Common to EFS and NEFS Series)

Slot Bottom Details

Slot Bottom Details

(HFS, CAF Series)

(GFS Series)

(NFSL, GNFS Series)

(EFS Series)

(NEFS Series)

Enlarged View of A

Enlarged View of A

Enlarged View of A

Enlarged View of A

Enlarged View of A

* 5.5 for Light Type (HFSL, HFSLF, HFSLT, NFSL).

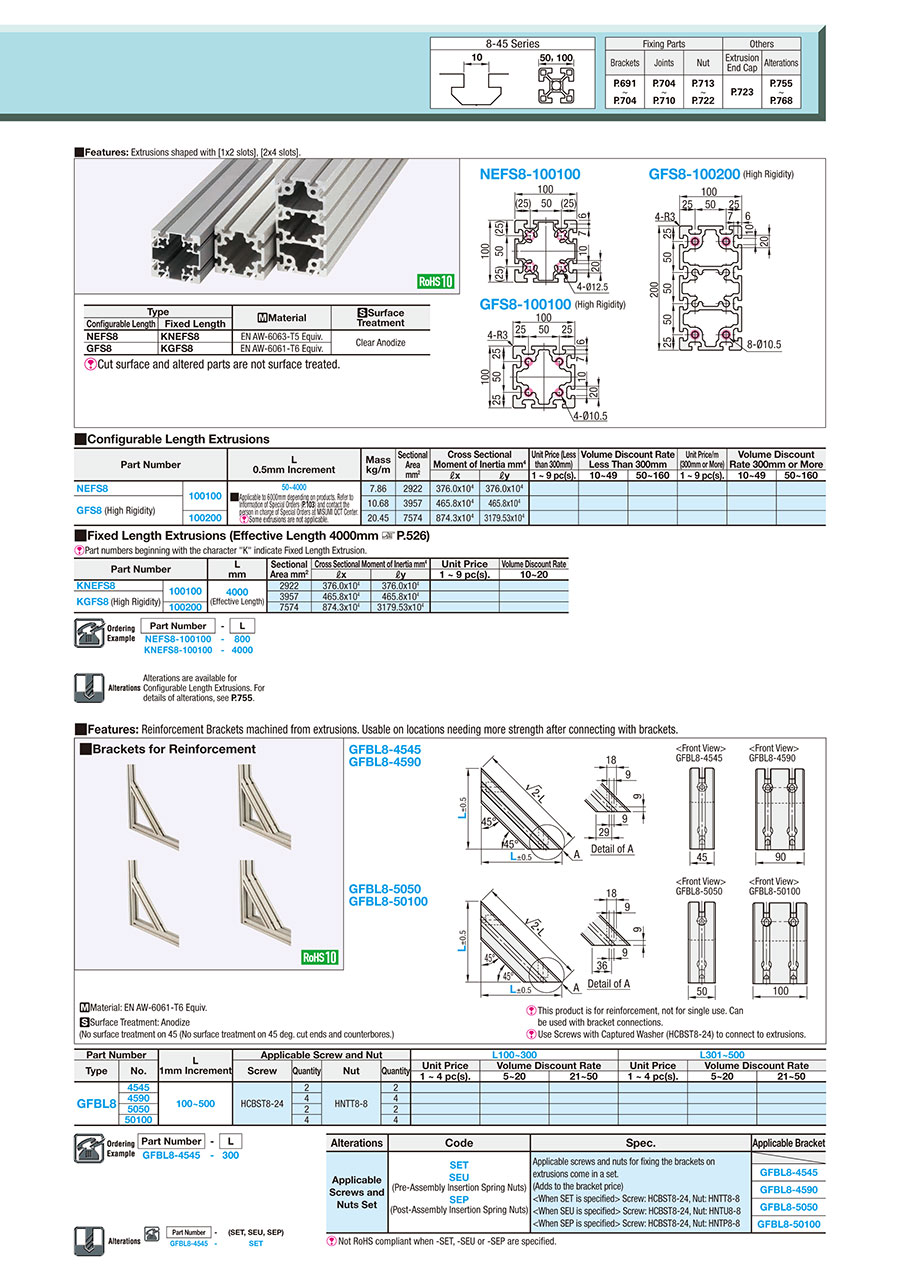

■8-45 Series

is an aluminum extrusion with a 10 mm slot width. Applicable to M8 bolts.

is an aluminum extrusion with a 10 mm slot width. Applicable to M8 bolts.

[ ! ] Cut surface and altered parts are not surface treated.

[ ! ] When tapped hole alterations are specified, the red circles on the outline drawing of the aluminum extrusion will be machined.

[ ! ] When tapped hole alterations are specified, the red circles on the outline drawing of the aluminum extrusion will be machined.

Configurable Length Extrusion Specification Table

| Part Number | — | L |

| HFS8−50100 | — | 800 |

| KHFS8−50100 | — | 4000 |

| Type | Material | Surface Treatment | Part Number | L 0.5 mm Increments (Tolerance ±0.5 mm) | Mass kg/m | Sectional Area mm2 | Cross Sectional Moment of Inertia mm4 | |

| ?x | ?y | |||||||

| HFS | EN AW-6061-T5 Equiv. | Clear Anodize | HFS8-50100 | 50 to 4000 | 5.96 | 2206 | 51.67 × 104 | 211.19 × 104 |

| HFS | EN AW-6061-T5 Equiv. | Black Anodize | HFSB8-50100 | 50 to 4000 | 5.96 | 2206 | 51.67 × 104 | 211.19 × 104 |

| EFS | EN AW-6061-T5 Equiv. | Clear Anodize | EFS8-50100 | 50 to 4000 | 5.39 | 1996 | 53.0 × 104 | 211.21 × 104 |

| EFS | EN AW-6061-T5 Equiv. | Black Anodize | EFSB8-50100 | 50 to 4000 | 5.39 | 1996 | 53.0 × 104 | 211.21 × 104 |

| GNFS | EN AW-6063-T6 Equiv. | Clear Anodize | GNFS8-50100 | 50 to 4000 | 7 | 2593 | 68.08 × 104 | 273.12 × 104 |

| GFS | EN AW-6061-T6 Equiv. | Clear Anodize | GFS8-50100 | 50 to 4000 | 7 | 2593 | 68.08 × 104 | 273.12 × 104 |

| NEFS | EN AW-6063-T5 Equiv. | Clear Anodize | NEFS8-50100 | 50 to 4000 | 5.39 | 1996 | 53.0 × 104 | 211.21 × 104 |

| NEFS | EN AW-6063-T5 Equiv. | Black Anodize | NEFSB8-50100 | 50 to 4000 | 5.39 | 1996 | 53.0 × 104 | 211.21 × 104 |

[ ! ] Applicable to 6,000 mm depending on products.

[ ! ] Not applicable to some extrusions.

Fixed Length Extrusion (Effective Length 4,000 mm) Specification Table

[ ! ] Part numbers beginning with the character "K" indicate Fixed Length Extrusion.| Type | Material | Surface Treatment | Part Number | Lmm (No tolerance regulation) | Sectional Area mm2 | Cross Sectional Moment of Inertia mm4 | |

| ?x | ?y | ||||||

| HFS | EN AW-6061-T5 Equiv. | Clear Anodize | KHFS8-50100 | 4000 | 2206 | 51.67 × 104 | 211.19 × 104 |

| HFS | EN AW-6061-T5 Equiv. | Black Anodize | KHFSB8-50100 | 4000 | 2206 | 51.67 × 104 | 211.19 × 104 |

| EFS | EN AW-6061-T5 Equiv. | Clear Anodize | KEFS8-50100 | 4000 | 1996 | 53.0 × 104 | 211.21 × 104 |

| EFS | EN AW-6061-T5 Equiv. | Black Anodize | KEFSB8-50100 | 4000 | 1996 | 53.0 × 104 | 211.21 × 104 |

| GNFS | EN AW-6063-T6 Equiv. | Clear Anodize | KGFNS8-50100 | 4000 | 2593 | 68.08 × 104 | 273.12 × 104 |

| GFS | EN AW-6061-T6 Equiv. | Clear Anodize | KGFS8-50100 | 4000 | 2593 | 68.08 × 104 | 273.12 × 104 |

| NEFS | EN AW-6063-T5 Equiv. | Clear Anodize | KNEFS8-50100 | 4000 | 1996 | 53.0 × 104 | 211.21 × 104 |

| NEFS | EN AW-6063-T5 Equiv. | Black Anodize | KNEFSB8-50100 | 4000 | 1996 | 53.0 × 104 | 211.21 × 104 |

The actual length with extra lengths on ends is more than 4000 mm (several tens of mm).

Fixed Length Extrusions need to be cut by users thus the exact length cannot be specified.

Alterations

[ ! ] MISUMI configurable length aluminum extrusion product can be utilized for structure building with highly enhanced design flexibility when the following various alteration options are applied.Some alterations are not applicable depending on types and sizes.

| Type | Alterations | Alteration Codes | App. Example | Contents |

|---|---|---|---|---|

| > End Tapping | End Tapping (Center Hole) | LTP/RTP/TPW LHP/RHP/HPW |  | Adds tapped holes on extrusion ends. Blind Joints which require this alteration (Screw Joint / Simple Joint) |

| End Tapping (4 Side Holes) | LSP/RSP/SPW |  | Adds tapped holes on extrusion corner ends. | |

| > Cutting Method Change | High Precision Cut | SC |  | Applies High Precision Cut with an overall length tolerance of L±0.2 (Standard = L±0.5). * Only applicable to L ≤ 1,500 |

| 45-Degree Cut | L□T45/R□T45 |  | Cuts with 45-degree angle. | |

| > Drill Wrench Hole | Wrench Hole in Fixed Position | LWP/RWP |  | Wrench access hole(s) for Blind Joints are drilled. The hole location will be aligned with the mating extrusion’s tapped hole location. Blind Joints which require this alteration (Screw Joint / Single Joint / Tapping Joint) |

| Extrusion End Cap The hole position moves by thickness | FL/FR |  | Offsets the wrench access hole for the thickness of Extrusion End Cap (3 mm). The extrusion end cap will be flat with the adjacent extrusion surface. | |

| Wrench Hole in Specified Position | AH/BH/AV/BV |  | Adds a wrench hole in a desired position from the left end. Use for Blind Jointing in beam sections, etc. | |

| > Counterboring | Counterbores in Specified Position | Z6/XA100 |  | Adds a counterbored hole in a desired position from the left end. Can be used for connecting extrusions or installing tables, etc. |

| > Blind Joints Dedicated Holes | D Hole | LDH/RDH |  | Adds required holes for Single Joint connections. (Single Joints) |

| S Hole | LSH |  | Adds required holes for Pre-Assembly. Insertion Double Joint connections. (Pre-Assembly Insertion Double Joints) | |

| M Hole | LMH |  | Adds required holes for Post-Assembly Insertion Double Joints, Center Joint connections. (Post-Assembly Insertion Double Joint / Center Joint) | |

| L Hole | JLP |  | Adds required holes for Parallel Joint connections. (Parallel Joints) | |

| > Other Machining | GNFS Series GFS Series End Tapping | LTS/RTS/TSW |  | Adds tapped holes on extrusion ends. This process is required for using extrusion end cap of the high rigidity plate type. (Plates for High Rigidity Type) |

| End Face C Chamfering | CW |  | Adds C Chamfering on extrusion ends. | |

| Labeling | ZZZ |  | Adds a sticker with catalog No. etc. on the aluminum extrusions. Although number of characters are limited, customer's own serial number or unit number can be labeled. |

Part number list

Number of items

| Part number |

|---|

| Order suspended |

| Order suspended |

| Order suspended |

Unit price (excluding VAT)(Unit price including VAT) | Standard shipping days |

|---|

- ( - ) | 5 working days |

- ( - ) | 5 working days |

- ( - ) | 5 working days |

612.88 € ( 729.33 € ) | 5 working days |

416.01 € ( 495.05 € ) | 5 working days |

505.25 € ( 601.25 € ) | 5 working days |

More Information

Basic information

Caution

- Cutting is free for this product. Please specify the length you prefer.