- inCAD Library Home

- > No.000183 Detachable turntable

No.000183 Detachable turntable

26

26

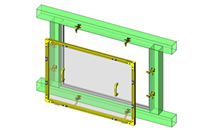

Changeover workbench easy to detach (the figure shows the one looked up from below)

Related Category

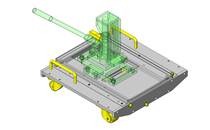

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

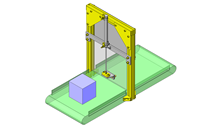

- Facilitating detaching of the turntable used in the product inspection/repair process.

- Operation

- Product inspection and product repair are conducted on a workbench. A turntable is not always necessary.

In case the turntable is not necessary, you can remove it by loosening the bolt at the center of the turntable. In the opposite case, the mounting position is repeated by the two positioning pins and holes on the workbench. You can fix the turntable by tightening the bolt at the center of the turntable.

- Product inspection and product repair are conducted on a workbench. A turntable is not always necessary.

Points for use

- The turntable is rotated manually.

Target workpiece

- Shape: Block

- Size: W430 x D250 x H70mm

- Weight: 6kg

Design Specifications

Operating Conditions or Design Requirements

- Turntable O.D.: Ø350mm

- External size (workbench) : W700 x D600 x H170mm

Selection Criteria for Main Components

- Select the R type for urethane molded bearings for supporting the prevention of deflection of the turntable.

Design Evaluation

Verification of main components

- Verify bearing durability for the load weight.

- Calculate life span of the bearing

- Conditional values: Bearing: Basic dynamic load rating of B6906ZZ: Cr = 7.25kN = 7250N

Workpiece weight: M = 6kg

Gravitational acceleration: g = 9.8m/s²

Accidental manual force: Assume to be Q = 200N - Gravity by the workpiece: W = M x g = 6 x 9.8 = 59N

- Let radial dynamic equivalent load be Pr, radial load Fr, thrust load Fa, radial factor X = 1, and thrust factor Y = 2.3 , then,

- Pr = X x Fr + Y x Fa Assume that force acting on the bearing, Po = M + Q, acts only in the z-axis direction (thrust load), and let radial load Fr = 0N, then we obtain the following:

- Thrust load: Fa = Po = M + Q = 259N, Pr = 1 x Fr + 2.3 x (M + Q) = 1 x 0 + 2.3 x 259 = 596N,

- Rated life (10⁶ rotations): L = (Cr / Pr)³ = (7250 / 596)³ = 1800 (10⁶ rotations) Thus, there exists sufficient margin.

- Conditional values: Bearing: Basic dynamic load rating of B6906ZZ: Cr = 7.25kN = 7250N

Other Design Consideration

- Securing repeatability of the turntable position and fixing the turntable with one bolt.

- Two round bores are configured for workbench positioning, and diamond-shaped positioning pins are effectively used.

Explore Similar Application Examples

Page

-

/

-