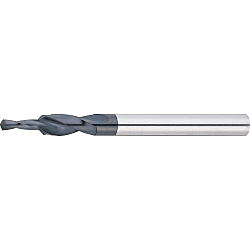

DLC Coated Carbide Stepped Drill for Aluminum Machining, Stub (Part Numbers)

- Volume Discount

-Excellent chip evacuation and sharpness due to high spiral shape

-Designed for frequent pre-drilling of M4 to M12 metric coarse holes

-2 types of step angles are available for chamfering and cutting

-Reduces chamfering process and achieves high drilling efficiency. (DLC-SC-SDR)

-Relief holes can be machined simultaneously when drilling pilot holes for bolts (DLC-SF-SDR).

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

Part Number

|

|---|

| DLC-SC-SDR6.8-24 |

| DLC-SF-SDR8.5-20 |

| DLC-SF-SDR8.5-30 |

| DLC-SF-SDR10.3-36 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Hole diameter (drill diameter) D (mm) | Groove Length L (mm) | Overall Length L (mm) | Step Length ℓ (mm) | Shank Diameter d | Diameter Tolerance | Tolerance of Shank Diameter | Use | Major Diameter D1 (φ) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

113.95 € | 1 | Available | 5 Days | 6.8 | 48 | 104 | 24 | 10 | 0 ~ -0.018 | 0 ~ -0.009 | For Chamfering | 10 | |

101.88 € | 1 | Available | 5 Days | 8.5 | 50 | 112 | 20 | 12 | 0 ~ -0.018 | 0 ~ -0.011 | Cutting | 12 | |

120.73 € | 1 | Available | 5 Days | 8.5 | 60 | 122 | 30 | 12 | 0 ~ -0.018 | 0 ~ -0.011 | Cutting | 12 | |

151.42 € | 1 | Available | 5 Days | 10.3 | 72 | 136 | 36 | 14 | 0 ~ -0.022 | 0 ~ -0.011 | Cutting | 14 |

Loading...

Specifications

| Model Number | Step Length ℓ | Large Diameter D1 | Groove Length ℓ1 | Overall Length L | Shank Diameter d | |

| Tip Diameter D | ||||||

| DLC-SC-SDR (For chamfering) DLC-SF-SDR (For cutting) | 3.4 | 8 | 6 | 21 | 73 | 6 |

| 12 | 6 | 25 | 77 | 6 | ||

| 4.3 | 10 | 7 | 26 | 79 | 7 | |

| 15 | 7 | 31 | 84 | 7 | ||

| 5.1 | 12 | 8 | 30 | 84 | 8 | |

| 18 | 8 | 36 | 90 | 8 | ||

| 6.8 | 16 | 10 | 40 | 96 | 10 | |

| 24 | 10 | 48 | 104 | 10 | ||

| 8.5 | 20 | 12 | 50 | 112 | 12 | |

| 30 | 12 | 60 | 122 | 12 | ||

| 10.3 | 24 | 14 | 60 | 124 | 14 | |

| 36 | 14 | 72 | 136 | 14 |

For Cutting Conditions, Refer to >>Click here.

More Information

● The DLC coating has excellent wear-resistant and welding-resistant properties that make it ideal for machining non-ferrous metals such as aluminum, copper, etc.

● A strong torsion shape provides superior discharge of cutting chips and cutting capability.

● Designed for very frequent drilling of pilot holes for M4 – M12 metric coarse thread.

● Two models of step angle are available for chamfering and cutting.

● High-efficiency hole drilling is achieved by reducing the chamfering process. (DLC-SC-SDR)

● When drilling pilot holes for bolts, relief holes can also be drilled at the same time. (DLC-SF-SDR)

Basic information

| work material | Cast Iron / Aluminum / Copper | Tool Material Type | Carbide | Shank Type | Straight Shank |

|---|---|---|---|---|---|

| Coating Y/N | Included | Coating Type | DLC | With/without Oil Hole | None |

| Point Angle(°) | 130 | Thinning | Included |

Configure

Basic Attributes

-

Hole diameter (drill diameter) D(mm)

-

Groove Length L(mm)

-

Overall Length L(mm)

-

Step Length ℓ(mm)

-

Type

- DLC-SC-SDR

- DLC-SF-SDR

Filter by standard shipping days

-

- All

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .