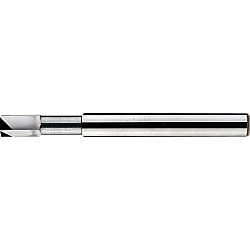

Carbide Precision Straight Reamer (Part Numbers)

It is capable of finishing holes with clean surface roughness compared to the normal reamer.

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Part Number | Minimum order quantity | Volume Discount | Tool Diameter (mm) | Groove Length (mm) | No. | Shank Diameter d (mm) | Overall Length L (mm) | Neck Length (ℓ1) (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 8 Days | 0.5 ~ 2 | 3 ~ 6 | 3 | 3 | 40 | 2 ~ 8 | ||

| 1 | 8 Days | 0.5 ~ 3 | 3 ~ 8 | 4 | 4 | 50 | 2 ~ 12 | ||

| 1 | 8 Days | 0.5 ~ 5.9 | 3 ~ 10 | 6 | 6 | 60 | 2 ~ 16 | ||

| 1 | 8 Days | 0.5 ~ 2 | 3 ~ 6 | 3 | 3 | 40 | 2 ~ 8 | ||

| 1 | 8 Days | 0.5 ~ 3 | 3 ~ 8 | 4 | 4 | 50 | 2 ~ 12 | ||

| 1 | 8 Days | 0.5 ~ 5.9 | 3 ~ 10 | 6 | 6 | 60 | 2 ~ 16 |

Loading...

Specifications

| Model Number | Flute Diameter D 0.01 mm Increment Designation | Blade Length ℓ 1 mm Increment Designation | Neck Length ℓ1 1 mm Increment Designation | Overall Length L | Shank Diameter d | |

| No. | ||||||

| P5SRM (Pentagonal type) P6SRM (Hexagonal type) | 3 | 0.50 ~ 1.00 | 3 ~ 4 | 2 ~ 3 | 40 | 3 |

| 1.01 ~ 2.00 | 4 ~ 6 | 4 ~ 8 | ||||

| 4 | 0.50 ~ 1.00 | 3 ~ 5 | 2 ~ 3 | 50 | 4 | |

| 1.01 ~ 2.00 | 4 ~ 6 | 4 ~ 8 | ||||

| 2.01 ~ 3.00 | 5 ~ 8 | 4 ~ 12 | ||||

| 6 | 0.50 ~ 1.00 | 3 ~ 5 | 2 ~ 3 | 60 | 6 | |

| 1.01 ~ 2.00 | 4 ~ 6 | 4 ~ 8 | ||||

| 2.01 ~ 3.00 | 5 ~ 8 | 4 ~ 12 | ||||

| 3.01 ~ 4.00 | 6 ~ 10 | 4 ~ 15 | ||||

| 4.01 ~ 5.90 | 7 ~ 10 | 4 ~ 16 |

More Information

● The surface roughness of holes can be finished very tidily compared to a normal reamer.

● Suitable for use with general-purpose machines.

■ Reference Examples of Machining Process

·For Hole Accuracy Ø 1.0 or Less

Center Drill --> Drill (diameter -0.1) --> Drill (diameter -0.02) --> Reamer

·For Hole Accuracy Greater Than Ø 1.0

Center Drill --> Drill (diameter -0.2) --> Drill (diameter -0.05) --> Reamer

■ Cutting Conditions

| Flute Diameter D | SKS | SKD | ||

| Feed Rate F (mm/min) | Revolution Speed (min-1) | Feed Rate F (mm/min) | Revolution Speed (min-1) | |

| 0.5 | 15 | 160 | 13 | 140 |

| 0.7 | 15 | 155 | 13 | 140 |

| 1.0 | 15 | 150 | 13 | 135 |

| 1.4 | 14 | 140 | 12 | 126 |

| 1.6 | 13 | 130 | 11 | 117 |

| 1.9 | 12 | 120 | 10 | 108 |

| 3.0 | 10 | 100 | 9 | 90 |

| 5.9 | 9 | 90 | 8 | 81 |

Basic information

| Shank type | End Mill Shank | Work Material | General Steel / Heat-Treated Steel / Stainless Steel / Cast Iron / Aluminum / Copper | Coating Presence | None |

|---|---|---|---|---|---|

| Groove Shape | Straight | Base-Blade Availability | None | Diameter Tolerance(mm) | -0.003 ~ 0 |

| Tool Material Type | Carbide |

Configure

Basic Attributes

-

Tool Diameter(mm)

-

Groove Length(mm)

-

No.

- 3

- 4

- 6

-

Shank Diameter d(mm)

-

Overall Length L(mm)

-

Neck Length (ℓ1)(mm)

-

Type

- P5SRM

- P6SRM

Filter by standard shipping days

-

- All

- 8 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .