Bellow couplings / grub screw clamping, hub clamping / bellows: stainless steel / body: stainless steel / BKXK, BKXS, BKXKV, BKXSV, BKXSY / ABP Antriebstechnik (BKXK 2129 04/10)

- Promotional pricing ends 30/11/2024

- Volume Discount

Product Details:

Manufacturer part number: BKXK 2129 04/10

Brand: ABP ANTRIEBSTECHNIK

Price: 45.01 €

Delivery time: 4 Days

Technical Data:

Allowable Torque Range: 1.01 to 3.00 N•m

Shaft Bore Dia. (machined) D1: 4 mm

Shaft Bore Dia. (machined) D2: 10 mm

Outer Dia. A: 21 mm

Overall Length W: 29 mm

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

BKXK 2129 04/10

Contents

- BKXK Ø16 / Ø21 / Ø24 Series

- BKXK Ø25 / Ø33 / Ø40 Series, BKXS Ø15 Series

- BKXS Ø19 / Ø20 / Ø25 Series

- BKXKV Ø16 Series, BKXSV Ø15 Series, BKXSY Ø20 Series

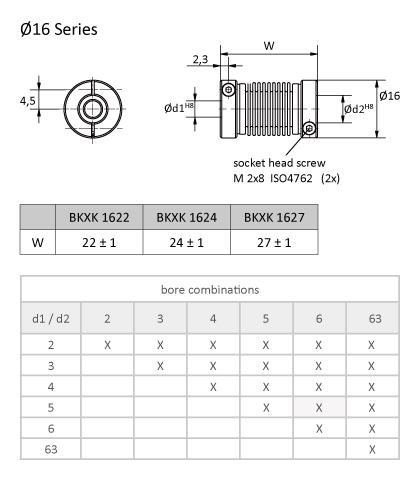

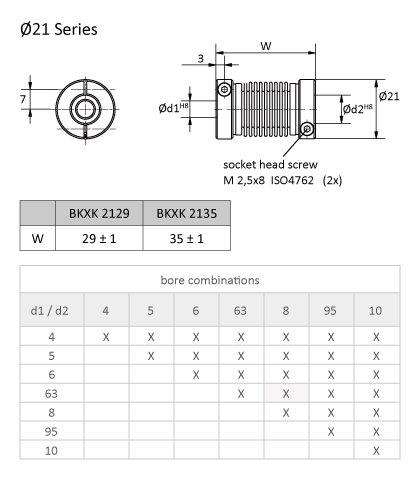

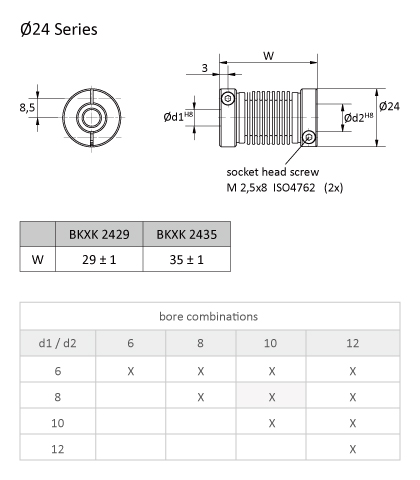

BKXK Ø16 / Ø21 / Ø24 Series

Technical Information

| Technical data | BKXK 1622 | BKXK 1624 | BKXK 1627 | BKXK 2129 | BKXK 2135 | BKXK 2429 | BKXK 2435 | |

|---|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Max. torque | Ncm | 40 | 40 | 40 | 120 | 100 | 120 | 100 |

| Max. offset off shafts | ||||||||

| Radial | mm | ± 0,2 | ± 0,25 | ± 0,3 | ± 0,25 | ± 0,3 | ± 0,25 | ± 0,3 |

| Axial | mm | ± 0,4 | ± 0,45 | ± 0,5 | ± 0,4 | ± 0,5 | ± 0,4 | ± 0,5 |

| Angular | Grad | ± 3 | ± 4 | ± 4 | ± 4 | ± 4 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 90 | 85 | 70 | 150 | 140 | 150 | 140 |

| Radial spring stiffness | N/mm | 40 | 20 | 15 | 25 | 10 | 25 | 10 |

| Moment of inertia | gcm2 | 2,1 | 2,2 | 2,6 | 9 | 9,5 | 15 | 15,2 |

| Max. clamping torque (M) | Ncm | 50 | 50 | 50 | 100 | 100 | 100 | 100 |

| Temperature range | °C | -30 to +120 | -40 to +140 | |||||

| Weight appr. | g | 6 | 6,5 | 7 | 15 | 16 | 17 | 18 |

| Material | Flange | Aluminium, anodised | ||||||

| Material | Bellow | Stainless steel | ||||||

M = tightening torque of the clamping screw

Drawings and Bore Combinations

Part No. Example: BKXK 1622 05/06

(Series ØW d1/d2)

Part No. Example: BKXK 2129 63/08

(Series ØW d1/d2)

Part No. Example: BKXK 2429 08/10

(Series ØW d1/d2)

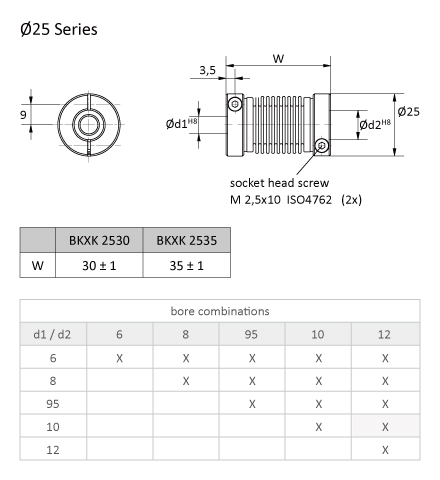

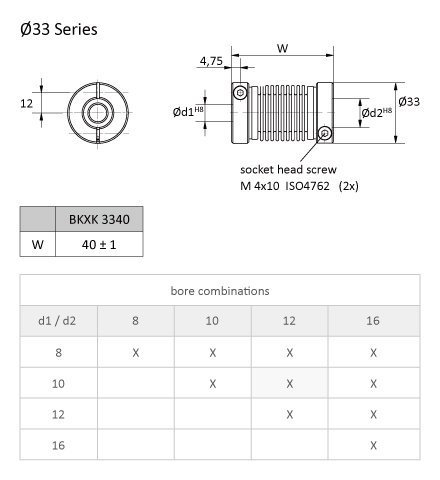

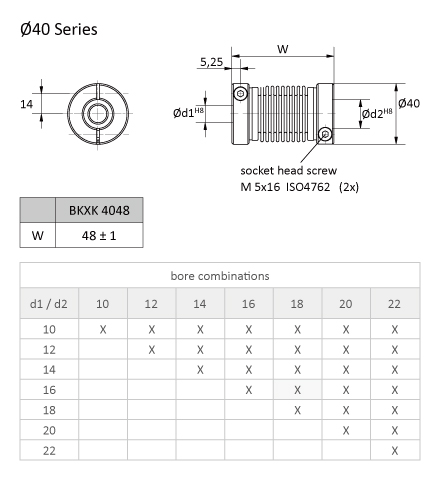

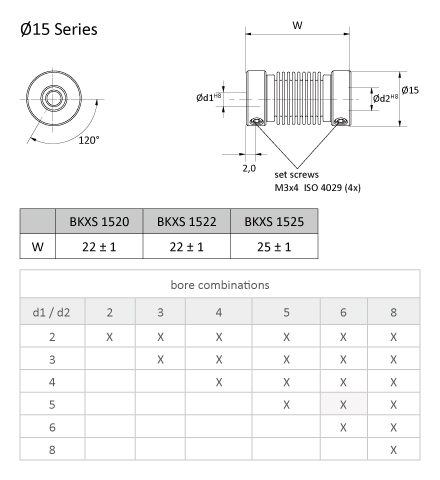

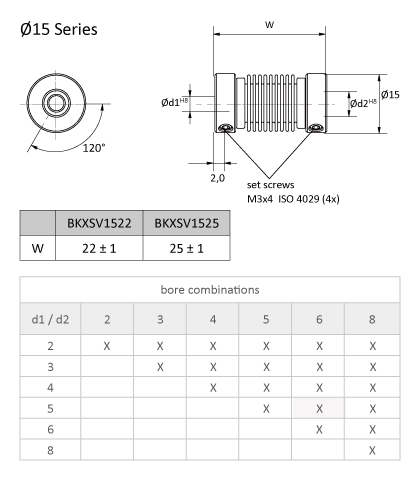

BKXK Ø25 / Ø33 / Ø40 Series, BKXS Ø15 Series

Technical Information

| Technical data | BKXK 2530 | BKXK 2535 | BKXK 3340 | BKXK 4048 | BKXS 1520 | BKXS 1522 | BKXS 1525 | |

|---|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 10.000 | 10.000 | 15.000 | 5.000 | 10.000 | 10.000 | 10.000 |

| Max. torque | Ncm | 200 | 200 | 500 | 1000 | 40 | 40 | 40 |

| Max. offset off shafts | ||||||||

| Radial | mm | ± 0,3 | ± 0,35 | ± 0,3 | ± 0,3 | ± 0,2 | ± 0,25 | ± 0,3 |

| Axial | mm | ± 0,4 | ± 0,45 | ± 0,5 | ± 0,5 | ± 0,4 | ± 0,45 | ± 0,5 |

| Angular | Grad | ± 4 | ± 4 | ± 3 | ± 1,5 | ± 3 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 220 | 183 | 750 | 350 | 90 | 85 | 70 |

| Radial spring stiffness | N/mm | 45 | 17,8 | 100 | 150 | 40 | 20 | 15 |

| Moment of inertia | gcm2 | 29,8 | 31 | 82 | 92 | 2 | 2,1 | 2,3 |

| Max. clamping torque (M) | Ncm | 100 | 100 | 4 | 8 | 70 | 70 | 70 |

| Temperature range | °C | -40 to +140 | ||||||

| Weight appr. | g | 20 | 22 | 60* | 22* | 6 | 6,5 | 7 |

| Material | Flange | Aluminium, anodised | ||||||

| Material | Bellow | Stainless steel | ||||||

* dependent on Ø

M = tightening torque of the clamping screw

Drawings and Bore Combinations

Part No. Example: BKXK 2530 10/12

(Series ØW d1/d2)

Part No. Example: BKXK 3340 10/12

(Series ØW d1/d2)

Part No. Example: BKXK 4048 16/18

(Series ØW d1/d2)

Part No. Example: BKXS 1520 05/06

(Series ØW d1/d2)

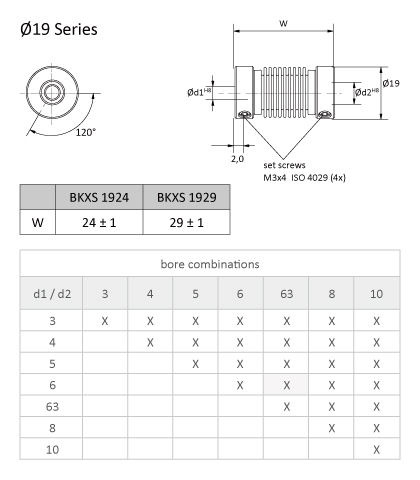

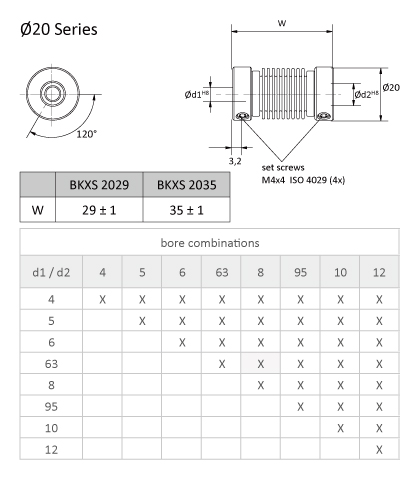

BKXS Ø19 / Ø20 / Ø25 Series

Technical Information

| Technical data | BKXS 1924 | BKXS 1929 | BKXS 2029 | BKXS 2035 | BKXS 2526 | BKXS 2531 | |

|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Max. torque | Ncm | 120 | 100 | 120 | 100 | 200 | 200 |

| Max. offset off shafts | |||||||

| Radial | mm | ± 0,25 | ± 0,3 | ± 0,25 | ± 0,3 | ± 0,3 | ± 0,35 |

| Axial | mm | ± 0,4 | ± 0,5 | ± 0,4 | ± 0,5 | ± 0,4 | ± 0,45 |

| Angular | Grad | ± 4 | ± 4 | ± 4 | ± 4 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 150 | 140 | 150 | 140 | 220 | 183 |

| Radial spring stiffness | N/mm | 25 | 10 | 25 | 10 | 45 | 17,8 |

| Moment of inertia | gcm2 | 7 | 9 | 8 | 9 | 19 | 20 |

| Max. clamping torque (M) | Ncm | 80 | 80 | 150 | 150 | 150 | 150 |

| Temperature range | °C | -40 to +140 | |||||

| Weight appr. | g | 10 | 11 | 15 | 16 | 17,5 | 18 |

| Material | Flange | Aluminium, anodised | |||||

| Material | Bellow | Stainless steel | |||||

M = tightening torque of the clamping screw

Drawings and Bore Combinations

Part No. Example: BKXS 1924 06/63

(Series ØW d1/d2)

Part No. Example: BKXS 2029 63/08

(Series ØW d1/d2)

Part No. Example: BKXS 2526 12/14

(Series ØW d1/d2)

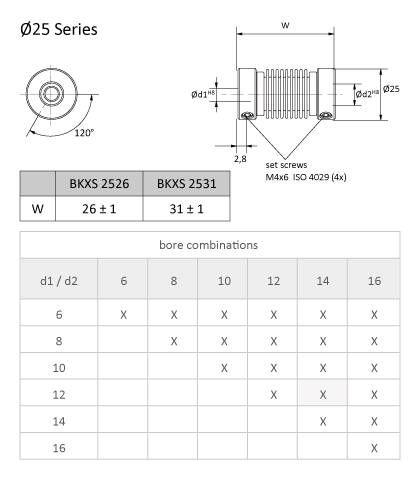

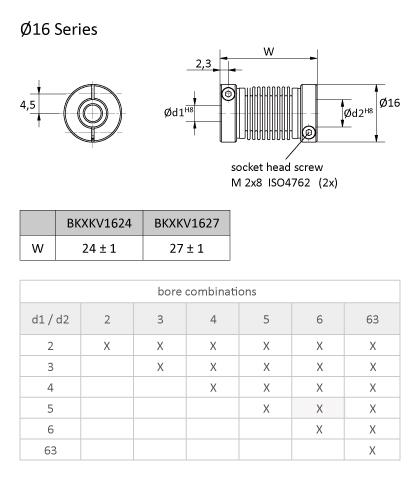

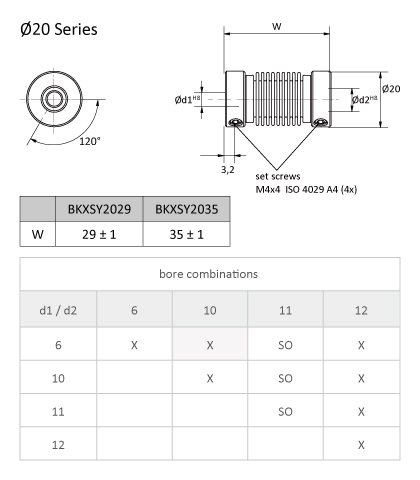

BKXKV Ø16 Series, BKXSV Ø15 Series, BKXSY Ø20 Series

Technical Information

| Technical data | BKXKV1624 | BKXKV1627 | BKXSV1522 | BKXSV1525 | BKXSY2029 | BKXSY2035 | |

|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Max. torque | Ncm | 100 | 100 | 100 | 100 | 120 | 100 |

| Max. offset off shafts | |||||||

| Radial | mm | ± 0,15 | ± 0,2 | ± 0,15 | ± 0,2 | ± 0,25 | ± 0,3 |

| Axial | mm | ± 0,4 | ± 0,45 | ± 0,4 | ± 0,45 | ± 0,4 | ± 0,5 |

| Angular | Grad | ± 1 | ± 1,5 | ± 1 | ± 1,5 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 115 | 110 | 115 | 110 | 150 | 140 |

| Radial spring stiffness | N/mm | 90 | 46 | 90 | 46 | 25 | 10 |

| Moment of inertia | gcm2 | 2,5 | 2,9 | 2,5 | 2,9 | 18 | 20 |

| Max. clamping torque (M) | Ncm | 50 | 50 | 50 | 50 | 70 | 70 |

| Temperature range | °C | -40 to +140 | -40 to +200 | ||||

| Weight appr. | g | 7 | 7 | 6,5 | 7 | 31,5 | 33 |

| Material | Flange | Aluminium, anodised | Stainless steel 1.4404 | ||||

| Material | Bellow | Stainless steel 1.4571 | |||||

M = tightening torque of the clamping screw

Through V4A 1.4404 stainless steel quality increased resistance to chlorides, sea water, fuels, toluene, aromatic and non-aromatic hydrocarbons,

alcohols, glycols, solvents and many chemicals.

Drawings and Bore Combinations

Part No. Example: BKXKV1624 05/06

(Series ØW d1/d2)

Part No. Example: BKXSV1522 05/06

(Series ØW d1/d2)

Part No. Example: BKXSY2029 06/10

(Series ØW d1/d2)

Part Number

|

|---|

| BKXK 2129 04/10 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Allowable Torque Range (N•m) | Shaft Bore Dia. (machined) D1 (mm) | Shaft Bore Dia. (machined) D2 (mm) | Outer Dia. A (mm) | Overall Length W (mm) | Max. Rotational Speed Range (r/min) | Feature | Body Material | Allowable Torque (Nm) | Max. Rotational Speed (r/min) | Allowable Lateral Misalignment Range (mm) | Allowable Lateral Misalignment (mm) | Allowable Angular Misalignment (deg) | Operating Temperature Range (°C) | Allowable Axial Clearance (±) (mm) | Moment of Inertia (g・cm2) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

45.01 € | 1 | Available | 4 Days | 1.01 to 3.00 | 4 | 10 | 21 | 29 | 4,001 to 10,000 | High Torsional Rigidity / High Torque / High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1 | 10000 | 0.21 to 0.40 | ±0.3 | ±4 | -30~+120 | ±0.5 | 9 |

Loading...

Basic information

| Type | Bellows Type | Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Application | Standard / Servo Motor / Encoder |

|---|---|---|---|---|---|

| Bellows Part Material | Stainless Steel |

This page is Bellow couplings / grub screw clamping, hub clamping / bellows: stainless steel / body: stainless steel / BKXK, BKXS, BKXKV, BKXSV, BKXSY / ABP Antriebstechnik, part number BKXK 2129 04/10.

You can find the detail information about specifications and dimensions on part number BKXK 2129 04/10.

Configure

Basic Attributes

-

Feature

-

Type

- BKXK 1622

- BKXK 1624

- BKXK 1627

- BKXK 2129

- BKXK 2135

- BKXK 2429

- BKXK 2435

- BKXK 2530

- BKXK 2535

- BKXK 4048

- BKXKY1624

- BKXKY1627

- BKXS 1520

- BKXS 1522

- BKXS 1525

- BKXS 1924

- BKXS 1929

- BKXS 2029

- BKXS 2035

- BKXS 2526

- BKXS 2531

- BKXSY1522

- BKXSY1525

- BKXSY2029

- BKXSY2035

-

Allowable Torque Range(N•m)

-

Shaft Bore Dia. (machined) D1(mm)

-

Shaft Bore Dia. (machined) D2(mm)

-

Outer Dia. A(mm)

-

Overall Length W(mm)

-

Max. Rotational Speed Range(r/min)

-

Body Material

-

Allowable Torque(Nm)

-

Max. Rotational Speed(r/min)

-

Allowable Lateral Misalignment Range(mm)

-

Allowable Lateral Misalignment(mm)

-

Allowable Angular Misalignment(deg)

-

Moment of Inertia(g・cm2)

-

Filter by CAD data type

- 3D

Filter by standard shipping days

-

- All

- Same day

- 3 Days or Less

- 4 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Variation of this product

| Part Number |

|---|

| BKXK 1622 03/06 |

| BKXK 1622 03/63 |

| BKXK 1622 04/04 |

| BKXK 2129 04/6.35 |

| BKXK 2129 04/9.52 |

| BKXK 2129 05/05 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Standard Shipping Days ? | Allowable Torque Range (N•m) | Shaft Bore Dia. (machined) D1 (mm) | Shaft Bore Dia. (machined) D2 (mm) | Outer Dia. A (mm) | Overall Length W (mm) | Max. Rotational Speed Range (r/min) | Feature | Body Material | Allowable Torque (Nm) | Max. Rotational Speed (r/min) | Allowable Lateral Misalignment Range (mm) | Allowable Lateral Misalignment (mm) | Allowable Angular Misalignment (deg) | Operating Temperature Range (°C) | Allowable Axial Clearance (±) (mm) | Moment of Inertia (g・cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

43.28 € | 1 | Available | 3 Days | 0.05 to 1.00 | 3 | 6 | 16 | 22 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Small / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 0.5 | 10000 | 0.02 to 0.2 | ±0.30 | ±5 | -30~120 | 0.5 | 2.1 | |

43.28 € | 1 | Available | 3 Days | 0.05 to 1.00 | 3 | 6.35 | 16 | 22 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Small / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 0.5 | 10000 | 0.02 to 0.2 | ±0.25 | ±2.5 | -30~120 | 0.4 | 2.5 | |

43.28 € | 1 | Available | 3 Days | 0.05 to 1.00 | 4 | 4 | 16 | 22 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Small / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 0.5 | 10000 | 0.02 to 0.2 | ±0.30 | ±4 | -30~120 | 0.5 | 2.1 | |

45.01 € | 1 | Available | 4 Days | 1.01 to 3.00 | 4 | 6.35 | 21 | 29 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 1 | 10000 | 0.21 to 0.40 | ±0.2 | ±1.5 | -30~+120 | ±0.45 | 9 | |

45.01 € | 1 | Available | 4 Days | 1.01 to 3.00 | 4 | 9.52 | 21 | 29 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 1 | 10000 | 0.21 to 0.40 | ±0.1 | ±3 | -30~+120 | ±0.1 | 9 | |

45.01 € | 1 | Available | 3 Days | 1.01 to 3.00 | 5 | 5 | 21 | 29 | 4,001 to 10,000 | High Torque / High Torsional Rigidity / High Durability / High Accuracy / Low Moment of Inertia / No Backlash / Vibration Insulation / Clean Environment / Heat Resistant | Aluminum | 1 | 10000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~120 | 0.5 | 3.2 |