Helical slit couplings / body: aluminium, stainless steel / WKAK, WKAS, WKAS, WKXK, WKXS / ABP Antriebstechnik (Part Numbers - CAD Download)

- Promotional pricing

- Volume Discount

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

Contents

- WKAK Ø12 / Ø14 / Ø16 / Ø19 / Ø25 / Ø30 Series

- WKAS Ø6,5 / Ø10 / Ø12 / Ø16 / Ø19 / Ø20 Series

- WKAS Ø25 / Ø30 Series

- WKXK Ø25 Series, WKXS Ø25 Series

WKAK Ø12 / Ø14 / Ø16 / Ø19 / Ø25 / Ø30 Series

Technical Information

| Technical data | WKAK 1215 | WKAK 1421 | WKAK 1625 | WKAK 1928 | WKAK 2532 | WKAK 3038 | |

|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 8.000 | 6.000 | 6.000 | 6.000 | 6.000 | 6.000 |

| Max. torque | Ncm | 25 | 50 | 60 | 80 | 100 | 150 |

| Max. offset off shafts | |||||||

| Radial | mm | ± 0,15 | ± 0,2 | ± 0,2 | ± 0,25 | ± 0,35 | ± 0,35 |

| Axial | mm | ± 0,2 | ± 0,25 | ± 0,3 | ± 0,4 | ± 0,5 | ± 0,5 |

| Angular | Grad | ± 2 | ± 3 | ± 3,5 | ± 4 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 2,5 | 4,5 | 5,5 | 8 | 16 | 19 |

| Radial spring stiffness | N/mm | 55 | 22 | 30 | 36 | 45 | 60 |

| Moment of inertia | gcm2 | 1 | 1,9 | 3,8 | 8,7 | 29 | 76 |

| Max. clamping torque (M) | Ncm | 30 | 50 | 50 | 120 | 150 | 150 |

| Temperature range | °C | -30 to +150 | -30 to +120 | -30 to +150 | |||

| Weight appr. | g | 3,5 | 6,5 | 10 | 16 | 34 | 58 |

| Material | Flange | Aluminium | Aluminium anodised | ||||

M = tightening torque of the clamping screw

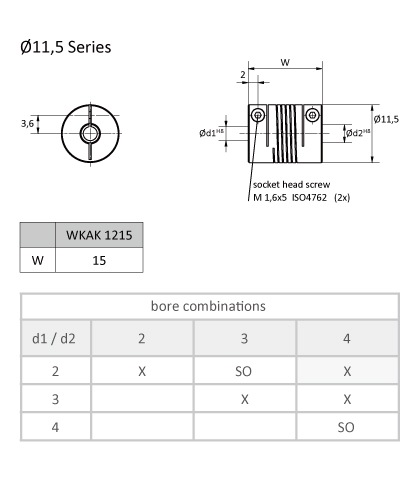

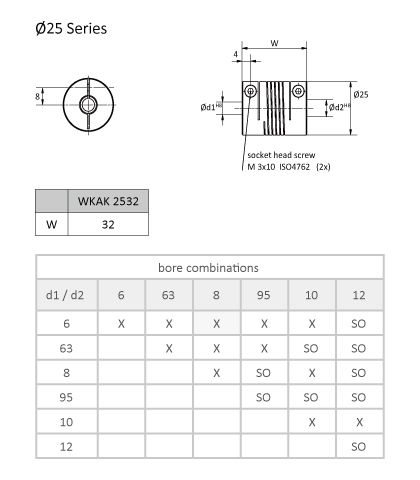

Drawings and Bore Combinations

Part No. Example: WKAK 1215 02/04

(Series ØW d1/d2)

SO = special bores at extra charge

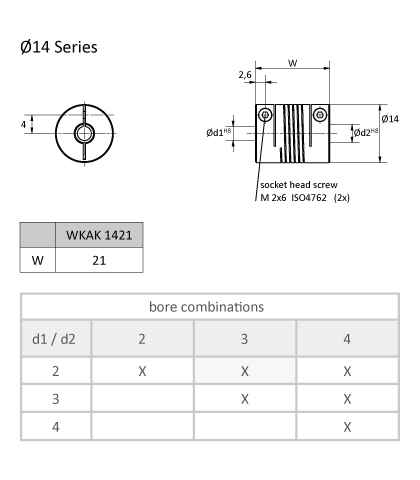

Part No. Example: WKAK 1421 02/03

(Series ØW d1/d2)

SO = special bores at extra charge

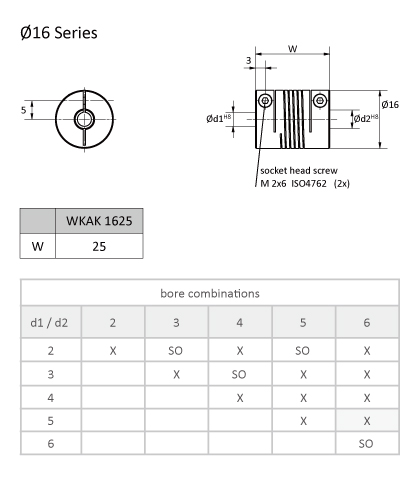

Part No. Example: WKAK 1625 05/06

(Series ØW d1/d2)

SO = special bores at extra charge

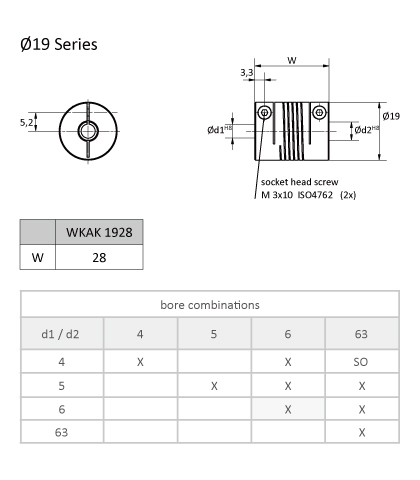

Part No. Example: WKAK 1928 06/06

(Series ØW d1/d2)

SO = special bores at extra charge

Part No. Example: WKAK 2532 06/08

(Series ØW d1/d2)

SO = special bores at extra charge

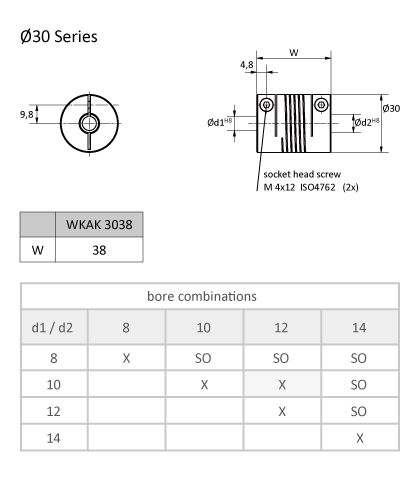

Part No. Example: WKAK 3038 10/12

(Series ØW d1/d2)

SO = special bores at extra charge

WKAS Ø6,5 / Ø10 / Ø12 / Ø16 / Ø19 / Ø20 Series

Technical Information

| Technical data | WKAS 6508 | WKAS 1015 | WKAS 1218 | WKAS 1622 | WKAS 1922 | WKAS 2019 | |

|---|---|---|---|---|---|---|---|

| Max. speed | min-1 | 8.000 | 8.000 | 8.000 | 8.000 | 8.000 | 8.000 |

| Max. torque | Ncm | 2 | 15 | 25 | 40 | 60 | 60 |

| Max. offset off shafts | |||||||

| Radial | mm | ± 0,1 | ± 0,15 | ± 0,15 | ± 0,2 | ± 0,25 | ± 0,25 |

| Axial | mm | ± 0,15 | ± 0,2 | ± 0,25 | ± 0,3 | ± 0,4 | ± 0,4 |

| Angular | Grad | ± 2 | ± 2 | ± 2,5 | ± 3 | ± 3,5 | ± 3,5 |

| Torsion spring stiffness | Nm/rad | 0,55 | 2,2 | 2,8 | 5 | 9 | 9 |

| Radial spring stiffness | N/mm | 24 | 22 | 28 | 34 | 40 | 40 |

| Moment of inertia | gcm2 | 0,02 | 0,34 | 0,83 | 3,2 | 6,7 | 6 |

| Max. clamping torque (M) | Ncm | 8 | 15 | 35 | 80 | 80 | 80 |

| Temperature range | °C | -30 to +150 | |||||

| Weight appr. | g | 0,5 | 2,4 | 4 | 9,5 | 13 | 12 |

| Material | Flange | Aluminium, anodised | Aluminium | ||||

M = tightening torque of the clamping screw

Helix area free turned from Ø 5 mm

Drawings and Bore Combinations

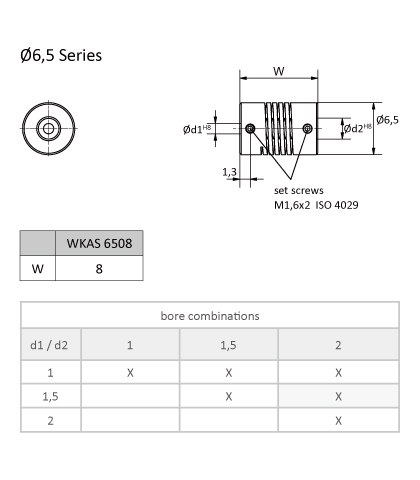

Part No. Example: WKAS 6508 1,5/02

(Series ØW d1/d2)

SO = special bores at extra charge

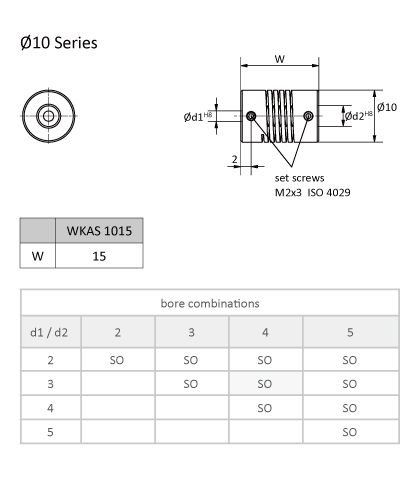

Part No. Example: WKAS 1015 03/04

(Series ØW d1/d2)

SO = special bores at extra charge

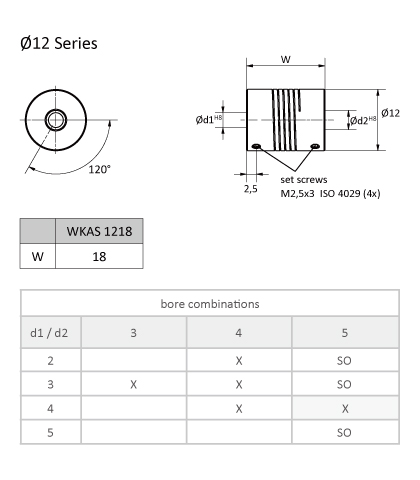

Part No. Example: WKAS 1218 04/05

(Series ØW d1/d2)

SO = special bores at extra charge

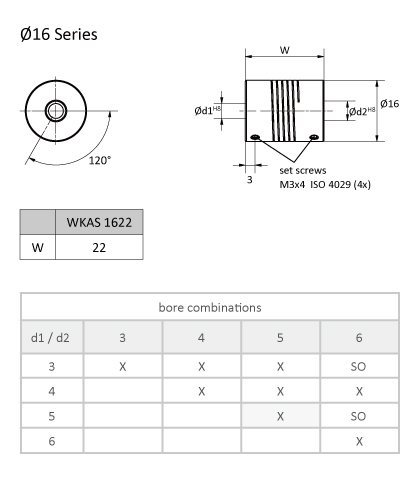

Part No. Example: WKAS 1622 05/05

(Series ØW d1/d2)

SO = special bores at extra charge

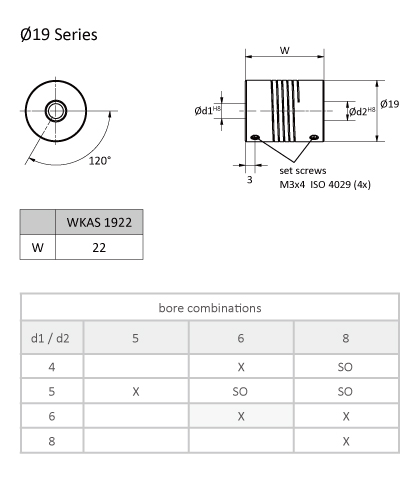

Part No. Example: WKAS 1922 06/06

(Series ØW d1/d2)

SO = special bores at extra charge

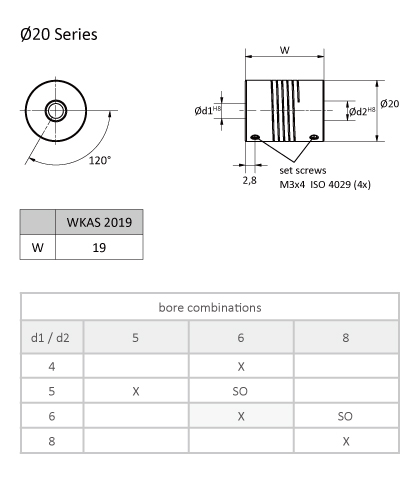

Part No. Example: WKAS 2019 06/06

(Series ØW d1/d2)

SO = special bores at extra charge

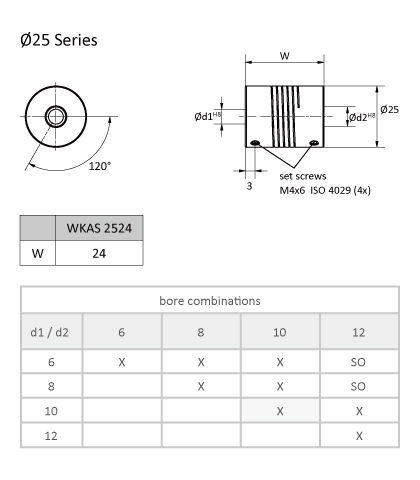

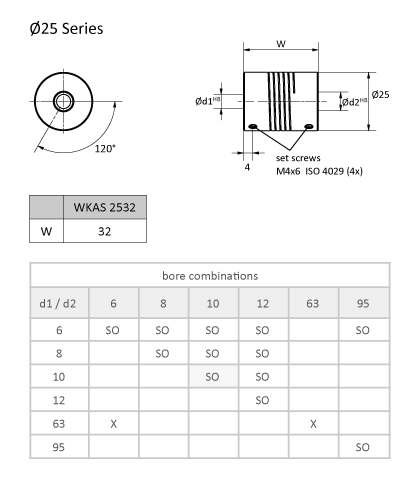

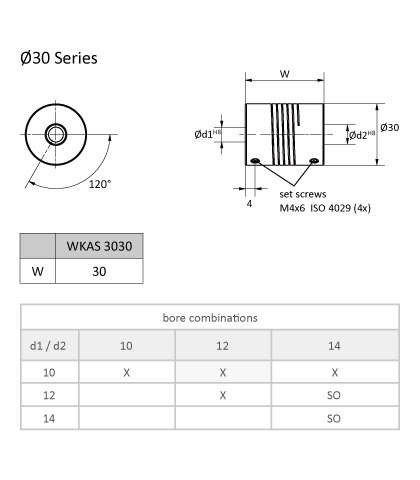

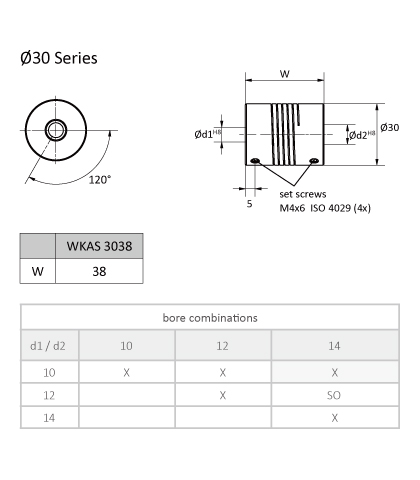

WKAS Ø25 / Ø30 Series

Technical Information

| Technical data | WKAS 2524 | WKAS 2532 | WKAS 3030 | WKAS 3038 | |

|---|---|---|---|---|---|

| Max. speed | min-1 | 8.000 | 8.000 | 8.000 | 8.000 |

| Max. torque | Ncm | 100 | 100 | 150 | 150 |

| Max. offset off shafts | |||||

| Radial | mm | ± 0,3 | ± 0,3 | ± 0,3 | ± 0,3 |

| Axial | mm | ± 0,5 | ± 0,5 | ± 0,5 | ± 0,5 |

| Angular | Grad | ± 4 | ± 4 | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 20 | 18 | 21 | 21 |

| Radial spring stiffness | N/mm | 60 | 50 | 60 | 60 |

| Moment of inertia | gcm2 | 22,2 | 30 | 57 | 76 |

| Max. clamping torque (M) | Ncm | 120 | 120 | 120 | 120 |

| Temperature range | °C | -30 to +150 | |||

| Weight appr. | g | 26 | 35 | 45 | 60 |

| Material | Flange | Aluminium anodised | |||

M = tightening torque of the clamping screw

Helix area free-turned

Drawings and Bore Combinations

WKAS 2524

Part No. Example: WKAS 2524 10/10

(Series ØW d1/d2)

SO = special bores at extra charge

WKAS 2532

Part No. Example: WKAS 2532 10/10

(Series ØW d1/d2)

SO = special bores at extra charge

WKAS 3030

Part No. Example: WKAS 3030 10/12

(Series ØW d1/d2)

SO = special bores at extra charge

WKAS 3038

Part No. Example: WKAS 3038 10/14

(Series ØW d1/d2)

SO = special bores at extra charge

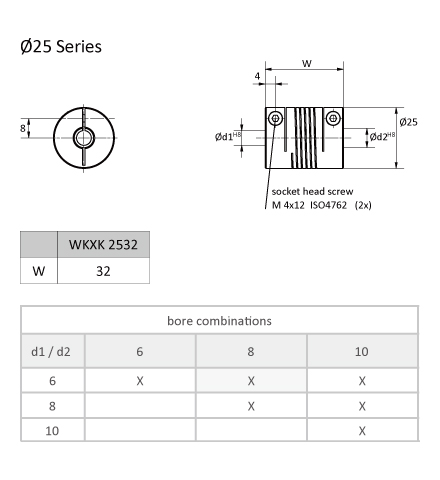

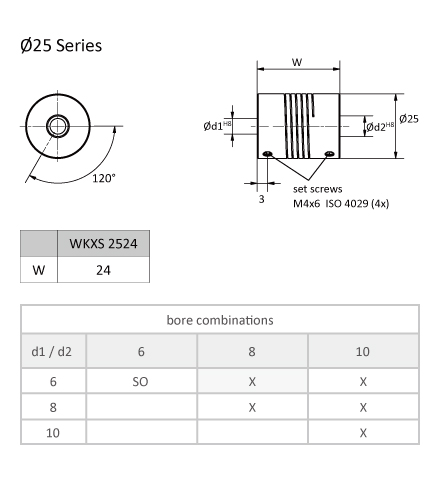

WKXK Ø25 Series, WKXS Ø25 Series

Technical Information

| Technical data | WKXK 2532 | WKXS 2524 | |

|---|---|---|---|

| Max. speed | min-1 | 6.000 | 8.000 |

| Max. torque | Ncm | 200 | 200 |

| Max. offset off shafts | |||

| Radial | mm | ± 0,35 | ± 0,3 |

| Axial | mm | ± 0,5 | ± 0,5 |

| Angular | Grad | ± 4 | ± 4 |

| Torsion spring stiffness | Nm/rad | 29 | 40 |

| Radial spring stiffness | N/mm | 150 | 250 |

| Moment of inertia | gcm2 | 84 | 64 |

| Max. clamping torque (M) | Ncm | 150 | 120 |

| Temperature range | °C | -30 to +180 | |

| Weight appr. | g | 88 | 65 |

| Material | Stainless steel 1.4104 | ||

M = tightening torque of the clamping screw

Helix area free-turned

WKXK 2532

Part No. Example: WKXK 2532 06/08

(Series ØW d1/d2)

WKXS 2524

Part No. Example: WKXS 2524 06/08

(Series ØW d1/d2)

SO = special bores at extra charge

Part Number

|

|---|

| WKAK 1625 03/05 |

| WKAK 1928 04/06 |

| WKAK 1928 05/06 |

| WKAK 1928 05/63 |

| WKAK 1928 06/06 |

| WKAK 1928 06/63 |

| WKAK 1928 63/63 |

| WKAK 2532 06/63 |

| WKAK 2532 10/12 |

| WKAS 2524 10/12 |

| WKAS 2524 12/12 |

| WKAS 2532 10/12 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Allowable Torque Range (N•m) | Shaft Bore Dia. (machined) D1 (mm) | Shaft Bore Dia. (machined) D2 (mm) | Outer Dia. A (mm) | Overall Length W (mm) | Feature | Body Material | Allowable Torque (Nm) | Max. Rotational Speed (r/min) | Allowable Lateral Misalignment Range (mm) | Allowable Lateral Misalignment (mm) | Allowable Angular Misalignment (deg) | Operating Temperature Range (°C) | Allowable Axial Clearance (±) (mm) | Moment of Inertia (g・cm2) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

41.95 € | 1 | Available | 3 Days | 0.05 to 1.00 | 3 | 5 | 16 | 25 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 0.5 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 3.8 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 4 | 6 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.4 | 9.5 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 5 | 6 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.4 | 2.9 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 5 | 6.35 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 8.7 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 6 | 6 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±5 | -30~150 | 0.5 | 2.2 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 6 | 6.35 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±5 | -30~150 | 0.5 | 2.1 | |

42.08 € | 1 | Available | 3 Days | 0.05 to 1.00 | 6.35 | 6.35 | 19 | 28 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 8.7 | |

43.13 € | 1 | Available | 3 Days | 0.05 to 1.00 | 6 | 6.35 | 25 | 32 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 29 | |

43.13 € | 1 | Available | 3 Days | 0.05 to 1.00 | 10 | 12 | 25 | 32 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 6000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 22.2 | |

36.19 € | 1 | Available | 3 Days | 0.05 to 1.00 | 10 | 12 | 25 | 24 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Small / Heat Resistant / Clean Environment / Vacuum Environment | Aluminum | 1.2 | 8000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.5 | 2.9 | |

36.19 € | 1 | Available | 3 Days | 0.05 to 1.00 | 12 | 12 | 25 | 24 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Small / Heat Resistant / Clean Environment / Vacuum Environment | Aluminum | 1.2 | 8000 | 0.21 to 0.40 | ±0.30 | ±5 | -30~150 | 0.5 | 2.9 | |

42.18 € 26.57 € | 1 | Available |

Same day

Stock | 0.05 to 1.00 | 10 | 12 | 25 | 32 | High Accuracy / High Durability / No Backlash / Low Moment of Inertia / Vibration Insulation / Heat Resistant / Clean Environment | Aluminum | 1.2 | 8000 | 0.21 to 0.40 | ±0.30 | ±4 | -30~150 | 0.4 | 2.1 |

Loading...

Basic information

| Type | With Slit | Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Application | Standard / Servo Motor / Stepping Motor / Encoder |

|---|---|---|---|---|---|

| Max. Rotational Speed Range(r/min) | 4,001 to 10,000 |

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Allowable Torque Range(N•m)

-

Shaft Bore Dia. (machined) D1(mm)

-

Shaft Bore Dia. (machined) D2(mm)

-

Outer Dia. A(mm)

-

Overall Length W(mm)

-

Feature

-

Body Material

-

Allowable Torque(Nm)

-

Max. Rotational Speed(r/min)

-

Allowable Lateral Misalignment Range(mm)

-

Allowable Angular Misalignment(deg)

-

Moment of Inertia(g・cm2)

-

Type

- WKAK 1421

- WKAK 1625

- WKAK 1928

- WKAK 2532

- WKAK 3038

- WKAS 1015

- WKAS 1218

- WKAS 1622

- WKAS 1922

- WKAS 2524

- WKAS 2532

- WKAS 3030

- WKAS 3038

- WKXK 2532

- WKXS 2524

-

Allowable Lateral Misalignment(mm)

-

Filter by CAD data type

- 3D

Filter by standard shipping days

-

- All

- Same day

- 3 Days or Less

- 4 Days or Less

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry