SANDVIK CoroTurn XS Solid Carbide Tool for Turning

・Type: XS cutting tool

・Work material: Steel, Stainless Steel, Non-ferrous metal, Heat-resistant alloy, titanium alloy, High Hardness Material

・Insert shape: CXS*

・Cutting Direction: Right-hand, Left-hand

・Grade type: CBN, Carbide

・Suitable for which type of machining?: Small part machining/internal machining

・eClass-5.1: 21011901

[Features]

・High precision and repeatability

・High locking precision

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Part Number | Minimum order quantity | Volume Discount | work material | Cutting Direction | O.D./ I.D. (For Threading) | Geometry/cutting edge | Type recommendation | Other designs | Customs tariff goods number | Customs tariff weight (kg) | ISO application area H | Holder: F dimension | Holder: Min. bore diameter | Total length l1 / l21 (mm) | ISO application area M | Holder: L dimension | Max. cutting depth (mm) | Corner radius RE (mm) | ISO application area P | Grade code | Machine-side mount/coupling size | Insert type | Size of insert/insert seat | Grade type | ISO application area S | ISO application area N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 1.05 mm/OHX = 13.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.2 | 0.1 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 1.55 mm/OHX = 13.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.2 | 0.1 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 2.05 mm/OHX = 13.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.2 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 2.55 mm/OHX = 18.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.2 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 3.05 mm/OHX = 18.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.2 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 3.45 mm/OHX = 13.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.3 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 3.45 mm/OHX = 18.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.3 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 3.45 mm/OHX = 23.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.3 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 3.45 mm/OHX = 28.00 mm | 82090020 | 0.012 | H - 1. Selection | - | - | - | - | - | APMX = 0.3 | 0.15 | - | 7015 | DCON = 4.00 mm | T = longitudinal turning | 4 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 4.25 mm/OHX = 13.00 mm | 82090020 | 0.018 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | - | T = longitudinal turning | 5 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 4.25 mm/OHX = 23.00 mm | 82090020 | 0.018 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | - | T = longitudinal turning | 5 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 4.25 mm/OHX = 28.00 mm | 82090020 | 0.018 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | - | T = longitudinal turning | 5 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | Internal Diameter | T098 | H | RMPX = 17°/WB = 4.25 mm/OHX = 33.00 mm | 82090020 | 0.018 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | - | T = longitudinal turning | 5 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | - | T098 | H | RMPX = 17°/WB = 5.25 mm/OHX = 18.00 mm | 82090020 | 0.021 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | DCON = 6.00 mm | T = longitudinal turning | 6 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | - | T098 | H | RMPX = 17°/WB = 5.25 mm/OHX = 23.00 mm | 82090020 | 0.021 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | DCON = 6.00 mm | T = longitudinal turning | 6 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | - | T098 | H | RMPX = 17°/WB = 5.25 mm/OHX = 28.00 mm | 82090020 | 0.021 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | DCON = 6.00 mm | T = longitudinal turning | 6 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | - | T098 | H | RMPX = 17°/WB = 5.25 mm/OHX = 33.00 mm | 82090020 | 0.021 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | DCON = 6.00 mm | T = longitudinal turning | 6 | CBN | - | - | ||

| 1 | Quote | High Hardness Material | Right-hand | - | T098 | H | RMPX = 17°/WB = 5.25 mm/OHX = 43.00 mm | 82090020 | 0.021 | H - 1. Selection | - | - | - | - | - | APMX = 0.5 | 0.2 | - | 7015 | DCON = 6.00 mm | T = longitudinal turning | 6 | CBN | - | - |

Loading...

Basic information

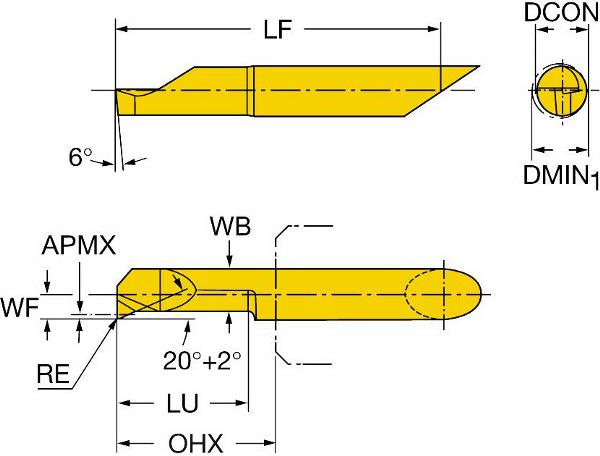

| Customs tariff weight unit | kg | Insert clearance angle | 6° | eClass-5.1 | 21011901 |

|---|---|---|---|---|---|

| Coolant | No | Number of cutting edges | 1 | Type | XS cutting tool |

| Insert shape | CXS* | Manufacturer | SANDVIK COROMANT | Suitable for which type of machining? | Small part machining/internal machining |

| Customs tariff weight per | 1 | Customs tariff country of origin | DE |

Configure

Basic Attributes

-

Cutting Direction

-

O.D./ I.D. (For Threading)

-

Geometry/cutting edge

-

Type recommendation

-

Other designs

-

Customs tariff goods number

-

Customs tariff weight(kg)

-

ISO application area H

-

Holder: F dimension

-

Holder: Min. bore diameter

-

Total length l1 / l21(mm)

-

ISO application area M

-

Holder: L dimension

-

Max. cutting depth(mm)

-

Corner radius RE(mm)

-

ISO application area P

-

Grade code

-

Machine-side mount/coupling size

-

Insert type

-

Size of insert/insert seat

-

Grade type

-

ISO application area S

-

ISO application area N

-

Type

-

work material

Filter by standard shipping days

-

- All

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .