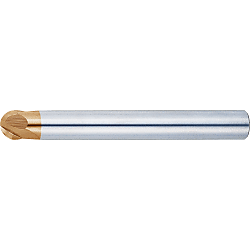

TS Coated Carbide Ball End Mill, Cutting Edge Rigidity Machining / For High-Hardness Steel Machining, 2-Flute / No Side Blade (Part Numbers)

- Volume Discount

-Ultra-fine-grained carbide base material suitable for machining high hardness steels is used (according to the manufacturer's cutting test results).

-MIAutomatic steelI-Original shape with rigid cutting edge treatment and no side cutting edge. High strength of the tool and cutting edge, resulting in a stable cutting edge shape and long tool life in high-speed milling

-Can be reground. Please refer to the "Regrinding Service" page for information on application methods, range of services, prices, etc.

- TS

- High-Hardness Steel

- 2 Flutes

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

Part Number

|

|---|

| TSC-CHBEM2N1 |

| TSC-CHBEM2N1.5 |

| TSC-CHBEM2N2 |

| TSC-CHBEM2N3 |

| TSC-CHBEM2N5 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Length Under Neck (ℓ1) (mm) | Shank Diameter (d) (mm) | Outer Diameter D (mm) | Figure | Length Under Neck (θ) (Degree) | Under Neck Diameter d1 (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

113.26 € | 1 | Available | 5 Days | 1 | 1 | 50 | 5 | 6 | 2 | 1 | 10° | 2 | |

121.38 € | 1 | Available | 5 Days | 1.5 | 1.5 | 60 | 7.5 | 6 | 3 | 1 | 10° | 3 | |

121.38 € | 1 | Available | 5 Days | 2 | 2 | 60 | 10 | 6 | 4 | 1 | 10° | 4 | |

132.38 € | 1 | Available | 5 Days | 3 | 3 | 80 | - | 6 | 6 | 2 | - | - | |

130.10 € | 1 | Available | 5 Days | 5 | 5 | 90 | - | 10 | 10 | 2 | - | - |

Loading...

Specifications

| Model Number | Flute Length ℓ |

Outer Diameter D |

Under Neck Diameter d1 |

Length Under Neck ℓ1 |

Overall Length L |

Shank Diameter d |

Figure | |

| Tip R |

||||||||

| TSC-CHBEM2N | 1 | 1 | 2 | 2 | 5 | 50 | 6 | 1 |

| 1.5 | 1.5 | 3 | 3 | 7.5 | 60 | 6 | 1 | |

| 2 | 2 | 4 | 4 | 10 | 60 | 6 | 1 | |

| 3 | 3 | 6 | - | - | 80 | 6 | 2 | |

| 5 | 5 | 10 | - | - | 90 | 10 | 2 |

For Cutting Conditions, Refer to >>Click here.

More Information

● It adopts a base material with super-ultra-fine particles suitable for high hardness steel machining (as per the results of cutting tests conducted by us).

● A Misumi original shape that has been treated for an extra rigid blade tip and does not have a side-surface cutting edge. High tool rigidity / blade tip hardness yields both a stable blade tip shape and long life when used for high speed milling machines.

● The TS coating consisting of a nitride-based composite film with a fully crystalline structure means that it yields a high oxidation resistance temperature and high hardness. It is ideal for high speed machining and dry machining of heat-treated / high hardness steel.

[ ! ]This product has a special shape with a performance that may not be reproducible without the use of Misumi's dedicated re-grinding.

Basic information

| Model | Bore | Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / High-Hardness Steel ~ HRC60 / High-Hardness Steel – HRC65 / Stainless Steel / Cast Iron | Number of Flutes(sheet) | 2 |

|---|---|---|---|---|---|

| Coating | For High Hardness (Silicone-Based) | R Precision(μm) | ±0.01 | Processing Applications | Curved Surface / Side Surface / Carving / R-Groove |

| Inventory Classification | Stocked Product | Torsion Availability | Included |

Configure

Basic Attributes

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Shank Diameter (d)(mm)

-

Type

- TSC-CHBEM2N

Filter by standard shipping days

-

- All

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .