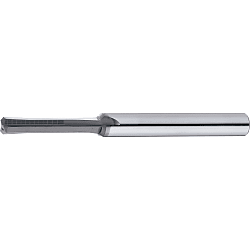

Carbide Boring End Mill (Part Numbers)

- Volume Discount

-Unique cutting edge shape enables drilling of various materials such as stainless steel and aluminium alloys

-Drilling is possible under cutting conditions of 60 m/min or more

-Compatible with various applications such as. Hole machining and high precision It can be used for finishing holes as it achieves the same dimensional accuracy and surface roughness as drilling and reaming

-Ideal for drilling precision threads with a high percentage of thread engagement

-It is able to correct variations in the diameter of the pilot hole, allows for improved hole position accuracy

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

Part Number

|

|---|

| TAC-BREM3R-2 |

| TAC-BREM3R-3 |

| TAC-BREM3R-4 |

| TAC-BREM3R-5 |

| TAC-BREM3R-6 |

| TAC-BREM3R-8 |

| TAC-BREM3R-10 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Tool Diameter (mm) | Groove Length (mm) | Diameter Tolerance (mm) | Shank Diameter d (mm) | Overall Length L (mm) | Effective Hole Drilling Depth (mm) | C Chamfer Plane | |

|---|---|---|---|---|---|---|---|---|---|---|---|

127.50 € | 1 | Available | 5 Days | 2 | 12 | 0 ~ 0.01 | 6 | 90 | 10 | 0.5 | |

127.50 € | 1 | Available | 5 Days | 3 | 17 | 0 ~ 0.012 | 6 | 90 | 15 | 0.5 | |

148.84 € | 1 | Available | 5 Days | 4 | 22 | 0 ~ 0.012 | 6 | 100 | 20 | 0.8 | |

154.23 € | 1 | Available | 5 Days | 5 | 27 | 0 ~ 0.012 | 6 | 100 | 25 | 0.8 | |

110.92 € | 1 | Available | 5 Days | 6 | 32 | 0 ~ 0.012 | 8 | 105 | 30 | 1 | |

148.39 € | 1 | Available | 5 Days | 8 | 42 | 0 ~ 0.015 | 10 | 105 | 40 | 1.5 | |

191.37 € | 1 | Available | 5 Days | 10 | 52 | 0 ~ 0.015 | 12 | 120 | 50 | 2 |

Loading...

Specifications

| Model Number | Effective Hole Drilling Depth | Blade Length ℓ | Overall Length L | Shank Diameter d | C Chamfer Plane | |

| Flute Diameter D | ||||||

| TAC-BREM3R | 2 | 10 | 12 | 90 | 6 | 0.5 |

| 3 | 15 | 17 | 90 | 6 | 0.5 | |

| 4 | 20 | 22 | 100 | 6 | 0.8 | |

| 5 | 25 | 27 | 100 | 6 | 0.8 | |

| 6 | 30 | 32 | 105 | 8 | 1. | |

| 8 | 40 | 42 | 105 | 10 | 1.5 | |

| 10 | 50 | 52 | 120 | 12 | 2. |

For Cutting Conditions, Refer to >>Click here.

More Information

(1) Suitable for a wide range of workpieces

- With a uniquely shaped cutting edge, holes can be drilled in various work materials such as stainless steel, aluminum alloy, etc.

(2) High-speed cutting is now a reality

- Drilling is performed with 60 m or more cutting conditions per minute.

(3) Various uses including hole finishing and high-accuracy pilot holes

- Use for hole finishing to achieve a precision in dimensions / surface roughness that is equivalent to boring and reaming.

- Ideal for drilling high-accuracy pilot holes for screws with a high catch rate.

- Since a correction can be made for variations in the pilot hole diameter, the positional accuracy of the holes can be improved.

- When a shrink-fit holder is applied, further high-precision hole drilling can be achieved.

(4) Wet, semi-dry, and dry cutting are all handled

- Wet cutting using cutting fluid, as well as semi-dry and dry cutting are all supported.

■ Machining Example

■ Machining Data

■ Comparison of Drilling Times  | ■ Hole Diameter Measurement Entrance: 6,020 mm Exit: 6,010 mm [Machining Speed Comparison (example)]

Machining time compared to a carbide reamer is approximately 1/12, and the equivalent hole finishing is achieved. |

Basic information

| Shank type | End Mill Shank | Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Aluminum | Coating Presence | Included |

|---|---|---|---|---|---|

| Groove Shape | Straight | Base-Blade Availability | None | Tool Material Type | Carbide |

| Coating Type | TiAlN |

Configure

Basic Attributes

-

Tool Diameter(mm)

-

Groove Length(mm)

-

Diameter Tolerance(mm)

-

Shank Diameter d(mm)

-

Overall Length L(mm)

-

Type

- TAC-BREM3R

Filter by standard shipping days

-

- All

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .