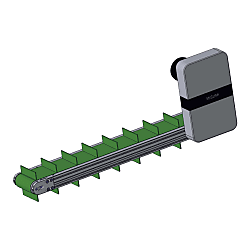

End Drive / Guided Belt / 3-Slot Frame / Pulley Dia. 50mm / CVDSAE / CVDSBE

(i)Remark

- Latest part number of conveyor is adding "E" to end of the original part number.

- Product discontinuation: The "Panasonic" motor specification (A) has been discontinued (no longer available) due to the discontinuation of production by the motor manufacturer. The "Oriental Motor" motor specification (B) is the recommended replacement. Please refer to the relevant product specifications for detailed product selection.

- Order Suspension: We are currently suspending orders for the Panasonic motor specification (A) and the Oriental Motor motor specification (B) due to the difficulty in procuring parts.

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Output (W) | Motor | Reduction Ratio | A | |

| Specification | Manufacturer | |||

| 40W | Induction Motor | Panasonic Motor | 7.5~180 | 142.0 |

| Oriental Motor | 7.5~18 | 147.0 | ||

| 25~180 | 165.0 | |||

| Variable Speed Motor | ||||

| Oriental Motor | 7.5~18 | 157.0 | ||

| 25~180 | 175.0 | |||

| Frame | Motor Cover | Pulley Holder | |

| Material | Aluminum | Aluminum | Aluminum |

| Surface Treatment | Clear Anodize | Painted | Painted |

Specifications

| Part Number | H | - | B | - | L | - | Motor | - | Belt Specification | - | Motor Manufacturer Selection | - | Number of Crosspieces | |||||||

| Output | - | Voltage | - | Specification | - | Gearhead Reduction Ratio | ||||||||||||||

| CVDSA | 30E | - | 100 | - | 1000 | - | 40 | - | TA230 | - | IM | - | 25 | - | WS | - | B | - | 10 | |

| Body Price | + | Motor, Belt Spec. Price | + | Price for Welding Crosspieces | = | Unit Price |

| Part Number | Crosspiece Height H Selection | B Selection | L 5mm Increment | Motor | Motor Manufacturer Selection The prices vary by manufacturer. | Number of Crosspieces Specified in increments of 1 | ||||||

| Output (W) | Voltage (V) | Specification | Gearhead Reduction Ratio | |||||||||

| CVDSA | 30E | 50 100 150 200 250 300 | 500~3000 | 40 | TA230 (Single-phase) | IM (Induction Motor) SCM (Variable Speed Motor) | 7.5 18 50 100 | 9 25 60 120 | 12.5 30 75 150 | 15 36 90 180 | A (Panasonic Motor) B (Oriental Motor) When motor specification is SCM (Variable Speed Motor),A (Panasonic Motor) is not applicable. | 5~100 * Number of crosspieces ≤ Perimeter (2L+160) / 50 Please note that the crosspiece pitch is automatically calculated by dividing the perimeter by the number of crosspieces. |

| NV (No Motor) | NM (No Motor) | NH (No Gearhead) | R (No Motor, Gearhead) | |||||||||

| CVDSB | 30E | 50 100 150 200 250 300 | 500~3000 | 40 | TA230 (Single-phase) | IM (Induction Motor) SCM (Variable Speed Motor) | 7.5 18 50 100 | 9 25 60 120 | 12.5 30 75 150 | 15 36 90 180 | A (Panasonic Motor) B (Oriental Motor) When motor specification is SCM (Variable Speed Motor),A (Panasonic Motor) is not applicable. | 5~100 * Number of crosspieces ≤ Perimeter (2L+160)/50 Please note that the crosspiece pitch is automatically calculated by dividing the perimeter by the number of crosspieces. |

| NV (No Motor) | NM (No Motor) | NH (No Gearhead) | R (No Motor, Gearhead) | |||||||||

When "No motor, gearhead" is selected, the motor mounting hole pitch will vary depending on the motor's power rating. Please see Technical Information in our Conveyor Selection web site for the dimension details.

When "No motor, gearhead" is selected, this unit will be delivered unassembled. The customer is to assemble the unit according to the included assembly instructions. See our Conveyor Selection site for assembly procedures and packaging details.

Installation must be done by two or more persons. Make sure to perform meandering adjustments again when using it on a slope. Using it without readjustments may cause meandering, resulting in a breakage to the belt.

When the operation stops with a workpiece placed on the conveyor on a slope, the belt might rotate in reverse direction, which may cause the workpiece to fall. To avoid this, specify the motor with electromagnetic brake in alterations when using the conveyor on a slope. For details, see Here.

Make sure to secure the stand with anchors when using the conveyor on a slope.

When using the conveyor on a slope, the gradient must not exceed 30°.

Belt may deflect up to about 50mm by its own weight.

* The pitch for crosspieces is automatically determined by the specified number of pitches. Please note that pitches with decimal part will be considered as target dimensions.

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| CVDSA30E-[50,100,150,200,250,300]-[500-3000/5]-40-NV-[IM,NM,SCM]-[7.5,9,12.5,15,18,25,30,36,50,60,75,90,100,120,150,180,NH]-FS-[A,B,R]-[5-100/1] |

| CVDSA30E-[50,100,150,200,250,300]-[500-3000/5]-40-TA230-[IM,NM,SCM]-[7.5,9,12.5,15,18,25,30,36,50,60,75,90,100,120,150,180,NH]-FS-[A,B,R]-[5-100/1] |

| CVDSB30E-[50,100,150,200,250,300]-[500-3000/5]-40-NV-[IM,NM,SCM]-[7.5,9,12.5,15,18,25,30,36,50,60,75,90,100,120,150,180,NH]-HS-[B,R]-[5-100/1] |

| CVDSB30E-[50,100,150,200,250,300]-[500-3000/5]-40-TA230-[IM,NM,SCM]-[7.5,9,12.5,15,18,25,30,36,50,60,75,90,100,120,150,180,NH]-HS-[B,R]-[5-100/1] |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | [B] Belt Width (mm) | [L] Conveyor Length (mm) | Motor Output (W) | [TA] Motor Voltage (Single Phase) * International (V) | Motor Voltage (No Motor) | Motor Type | Gearhead Reduction Ratio | Belt Specifications | Number of Guides (pc(s).) | Motor Manufacturer Selection | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 28 Days | 50 ~ 300 | 500 ~ 3000 | 40 | - | [NV] No Motor | [IM] Induction Motor / [NM] No Motor / [SCM] Variable Speed Motor | 7.5 / 9 / 12.5 / 15 / 18 / 25 / 30 / 36 / 50 / 60 / 75 / 90 / 100 / 120 / 150 / 180 / [NH] No Gear Heads | - | 5 ~ 100 | [A] Panasonic Motor / [B] Oriental Motor / [R] No Motor Gear Head | ||

- | 1 | 28 Days | 50 ~ 300 | 500 ~ 3000 | 40 | 230 | - | [IM] Induction Motor / [NM] No Motor / [SCM] Variable Speed Motor | 7.5 / 9 / 12.5 / 15 / 18 / 25 / 30 / 36 / 50 / 60 / 75 / 90 / 100 / 120 / 150 / 180 / [NH] No Gear Heads | - | 5 ~ 100 | [A] Panasonic Motor / [B] Oriental Motor / [R] No Motor Gear Head | ||

- | 1 | 28 Days | 50 ~ 300 | 500 ~ 3000 | 40 | - | [NV] No Motor | [IM] Induction Motor / [NM] No Motor / [SCM] Variable Speed Motor | 7.5 / 9 / 12.5 / 15 / 18 / 25 / 30 / 36 / 50 / 60 / 75 / 90 / 100 / 120 / 150 / 180 / [NH] No Gear Heads | [HS] for special hygienic requirements and Oil Resistance - Green | 5 ~ 100 | [B] Oriental Motor / [R] No Motor Gear Head | ||

- | 1 | 28 Days | 50 ~ 300 | 500 ~ 3000 | 40 | 230 | - | [IM] Induction Motor / [NM] No Motor / [SCM] Variable Speed Motor | 7.5 / 9 / 12.5 / 15 / 18 / 25 / 30 / 36 / 50 / 60 / 75 / 90 / 100 / 120 / 150 / 180 / [NH] No Gear Heads | [HS] for special hygienic requirements and Oil Resistance - Green | 5 ~ 100 | [B] Oriental Motor / [R] No Motor Gear Head |

Loading...

Price List

| Part Number | H | B | Body Price 1 ~ 2 pc(s). | Unit Price for Welding Crosspieces (Body Price +) | |||||||||||||||||||

| L500~ 600 | L605~ 700 | L705~ 800 | L805~ 900 | L905~ 1000 | L1005~ 1100 | L1105~ 1200 | L1205~ 1300 | L1305~ 1400 | L1405~ 1500 | L1505~ 1600 | L1605~ 1700 | L1705~ 1800 | L1805~ 1900 | L1905~ 2000 | L2005~ 2200 | L2205~ 2400 | L2405~ 2600 | L2605~ 2800 | L2805~ 3000 | ||||

| CVDSA (Belt for Food, White) | 30E | 50 | |||||||||||||||||||||

| 100 | - | ||||||||||||||||||||||

| 150 | - | - | |||||||||||||||||||||

| 200 | - | - | - | ||||||||||||||||||||

| 250 | - | - | - | - | |||||||||||||||||||

| 300 | - | - | - | - | |||||||||||||||||||

| CVDSB (Oil Resistant Belt for Food, Green) | 30E | 50 | |||||||||||||||||||||

| 100 | - | ||||||||||||||||||||||

| 150 | - | - | |||||||||||||||||||||

| 200 | - | - | - | ||||||||||||||||||||

| 250 | - | - | - | - | |||||||||||||||||||

| 300 | - | - | - | - | |||||||||||||||||||

Example of Use

Basic information

| Driving Type | Head Drive | Max. Mass of Conveyed Material(kg) | 15 | Belt Type | Flat Belt |

|---|---|---|---|---|---|

| With Meandering Prevention Crosspiece | Pulleys crowned for meandering prevention | Max. Conveyance Speed(m/min) | 37.7 | Tail Roller Dia. D (Tail Transfer Part R)(mm) | 50 |

| Drive Roller Dia.(mm) | 50 | Reverse Switch Option | Not Provided |

Configure

Basic Attributes

-

[B] Belt Width(mm)

-

[L] Conveyor Length (mm)

-

Motor Output(W)

-

[TA] Motor Voltage (Single Phase) * International(V)

-

Motor Voltage (No Motor)

- [NV] No Motor

-

Motor Type

- [IM] Induction Motor

- [NM] No Motor

- [SCM] Variable Speed Motor

-

Gearhead Reduction Ratio

-

Belt Specifications

- [HS] for special hygienic requirements and Oil Resistance - Green

-

Number of Guides(pc(s).)

-

Motor Manufacturer Selection

- [A] Panasonic Motor

- [B] Oriental Motor

- [R] No Motor Gear Head

-

Type

- CVDSAE

- CVDSBE

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 28 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .