Bearing housings / flange selectable / counterbore / double deep groove ball bearing / material selectable / coating selectable (Part Numbers - CAD Download)

- Promotional pricing ends 30/11/2024

- Volume Discount

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Bearings with Housing

Available dimensions and tolerances can be found under the tab More information.

| Type | Material | Surface Treatment | |||

| Round | Square | Compact | Bearing | Housing | Housing |

| BGRCB | BGSCB | BGCCB | Steel | EN 1.1191 Equiv. | Black Oxide |

| BGRC | BGSC | BGCC | Electroless Nickel Plating | ||

| BARC | BASC | BACC | Aluminum Alloy 2000 series | Clear Anodize | |

| SBARC | SBASC | SBACC | *Stainless Steel | ||

| SBGRC | SBGSC | SBGCC | EN 1.4301 Equiv. | - | |

Further specifications can be found under the tab More information.

Information about tolerances can be found under ball bearing table / tolerances as PDF

| Part Number | - | L | ||||

| Type | Bearing | Seal | ||||

| BGCC BGRC | 6200 6202 | VV ZZ | - - | 30 35 | ||

Note: the bearing number used is included in the bearing housing part number.

Bearings with Housing/Bearing Housings/Bearing Units Selection Details

- Housing material: aluminum, steel, stainless steel

- Coatings: uncoated, burnished, anodized, nickel-plated

- Ball bearing material: steel, stainless steel

- ISO tolerances: Ball bearing table/tolerances available as PDF

- bearing housing types: round flange, square flange, compact flange, guide flange, T-shape, L-shape, block shape

- Ball bearing types: deep groove ball bearings, angular ball bearings

- Inner diameter: from 3 mm to 50 mm

The variety of bearing housings can be found in the Overview of the Types of Pedestal Bearings available as a PDF.

The different designs of the flange bearings can be found in the Overview of the Types of Flange Bearing Housing available as PDF.

Description/Basics

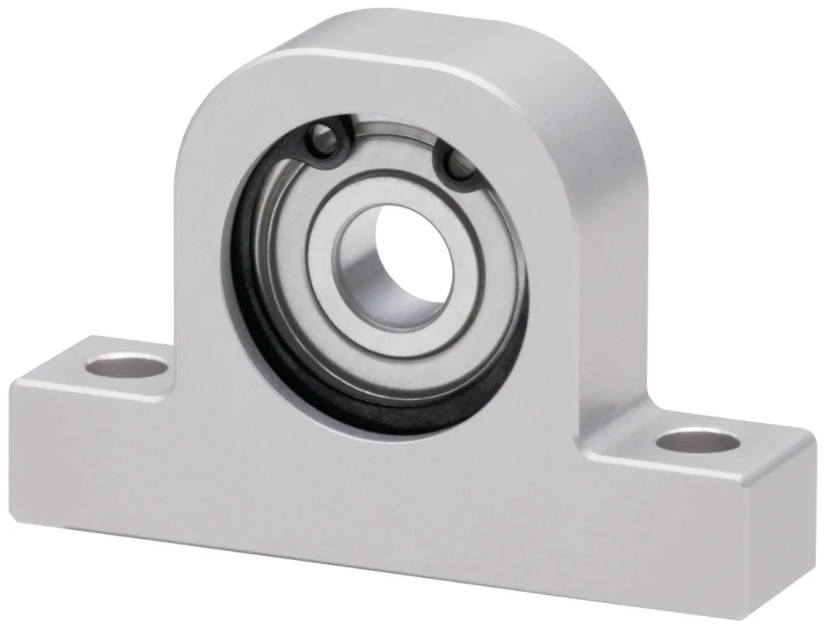

Bearing housings are highly robust and allow for easy and quick assembly. They are used to accommodate rotating machine elements in mechanical engineering. The housing bearings are generally provided for receiving rotary shafts or torsional shafts. Bearing housing types include pedestal bearings, flange bearings, tension bearings, and pillow blocks. They can be fitted with simple ball bearings. However, there are bearing housings in which angular contact ball bearings are installed that can also absorb axial forces. Housing bearings are available with single-row, double-row and three-row deep-groove ball bearings or angular contact ball bearings. The different designs of the bearing housings can be used horizontally or vertically. For horizontal mounting, MISUMI offers bearing housings as a vertical pedestal bearing in L- and T-shape, as well as a square bearing block. Flange bearing housings, also called flange bearings, are often used for vertical mounting. A bearing unit from MISUMI, whether a pedestal bearing or a flange bearing, is available in double or triple bearings (with rolling bearings) to absorb any lever forces.

The ball bearings are secured in the bearing housings with retaining rings or bearing covers. The bearing can thus be replaced as needed.

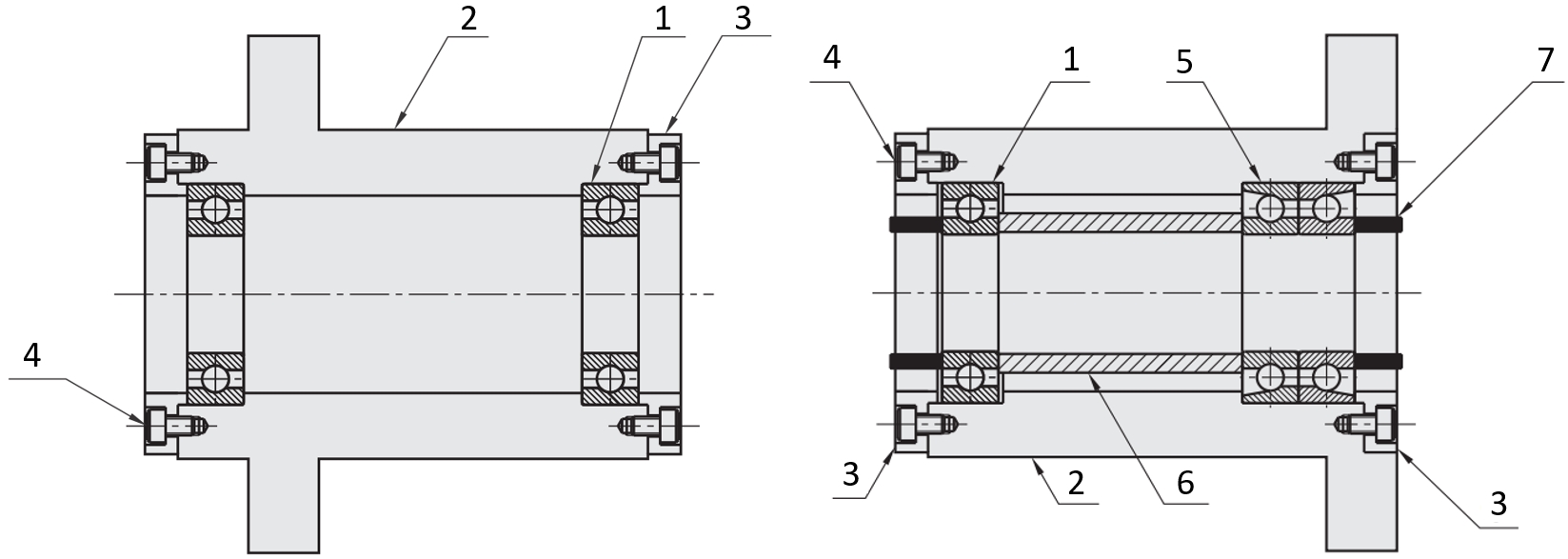

Two-row and multi-row bearing housings

Multi-row bearing housings are well-suited for applications subjected to lever forces. They can contribute to increased rotational stability as a flange bearing housing or a pedestal bearing housing.

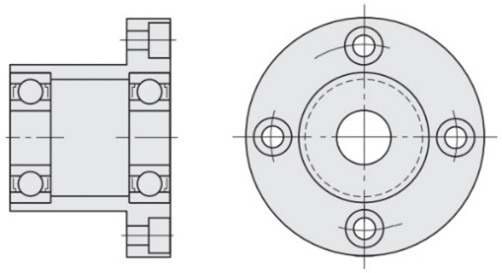

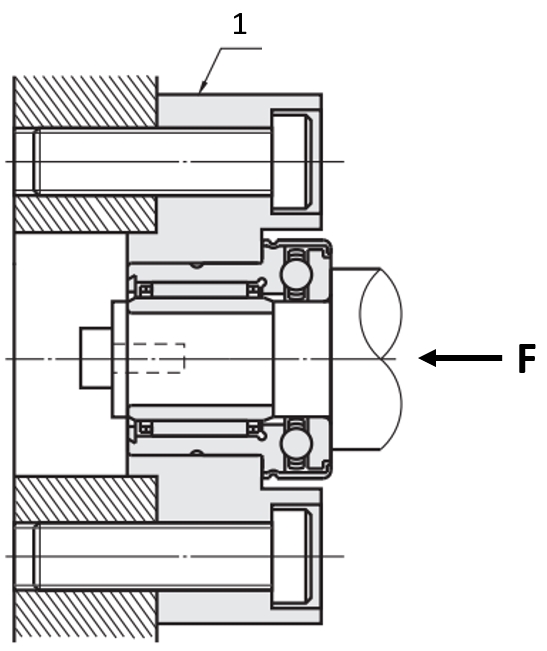

The flange bearing with angular ball bearing and screwed bearing cover can be used as a fixed bearing. In this case, a floating bearing is recommended in the assembly group.

The combination of fixed and floating bearings can ensure length compensation. This prevents an undesirable compression of a shaft or a threaded drive. A compression can create an imbalance and thus vibrations in an application and lead to inaccuracy

Ball bearing seals for bearing housings

ZZ (2Z): double encapsulated

VV (2RZ): contactless rubber seal

DD (2RS): contact rubber seal (slightly increased friction)

Areas of Application

MISUMI’s bearing housings, flange bearings and pedestal bearings can be used in almost all applications. Bearing housings are often used as flange bearings or pedestal bearings for the bearing of ball screws and rotary shafts. In addition, they are often found in conveyor belts, or in the bearings of shafts in timing belts, as well as chain transmission. As a fixed and floating bearing, the bearing units can withstand high loads and speeds of rotation. In addition, the encapsulated or sealed bearings are protected from external influences.

Materials

Bearing unit housings are available in steel, stainless steel, and aluminum. Due to the alterations of selecting the ball bearings, a pedestal bearing housing or flange bearing housing can consist of various types of materials. The bearing housings are optionally installed with steel or stainless steel ball bearings. In addition, a bearing housing that can be used as a fixed bearing can additionally be provided on the bearing housing with a rubber seal.

Coatings

MISUMI’s pedestal bearings and flange bearings made of steel can be optionally burnished, painted, chemically nickel-plated. The aluminum bearing housings can be anodized to provide the best possible protection against corrosion depending on the need or the environmental conditions.

Dimensions

Types of pedestal bearings

Shape | Mounting method | Features |

T-shape (extruded) |

| - economically extruded housing |

T-shape |

| - stable despite its narrow design |

L-shape |

| - Low width |

Block shape (internal thread) |

| - Fastened from underneath through the internal thread |

Block shape |

| - Low assembly height |

Straight |

| - Fastening from the front |

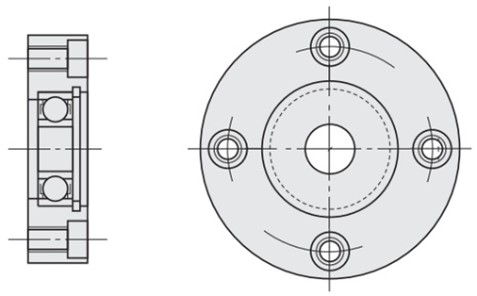

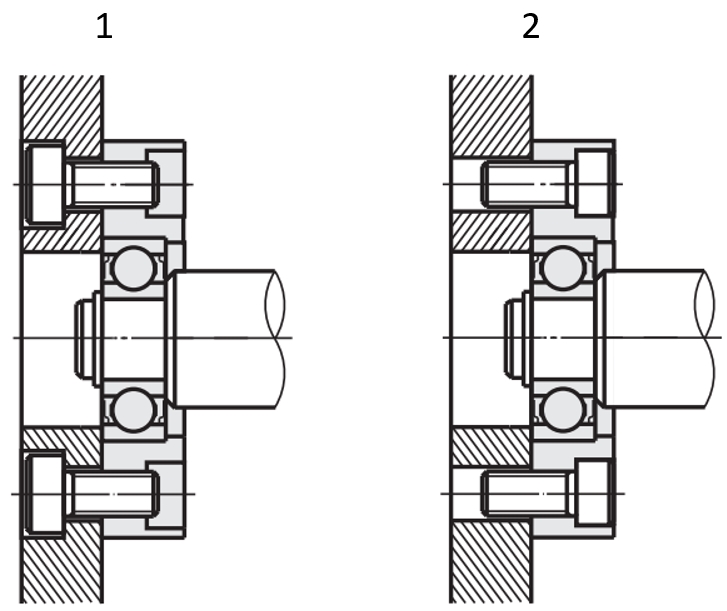

Flange bearing designs

Ball bearing | Design | utilisation |

Easy |

| - Can be used at several shaft positions |

With centering collar | - Often used to secure multiple locations | |

Double |

| - Suitable for heavy loads |

With centering collar | - Suitable for heavy loads |

Installation Information

When assembling bearing housings, care must be taken to ensure that they are installed without tension to prevent vibration, noise and damage. The holes or threads on the mounting surface should therefore be positioned as accurately as possible to prevent stresses on the shaft or spindle. In addition, dowel pins in the base plate can be a helpful option. Also, when installing the bearing housings, make sure that the contact surfaces are clean.

In addition, MISUMI offers special types of bearing housings, which have a positioning groove on the underside to predetermine a precise alignment.

The alteration [NA] allows for the bearing housings and ball bearings not to be delivered pre-assembled. This can significantly simplify assembly depending on the assembly procedure.

In some variants with angular contact bearings, the bearings must be greased during assembly.

Flange bearing housing with female thread

MISUMI offers another special form with the flange bearing with female thread. This flange bearing has the advantage that it can be mounted from the front and the rear. This flange bearing housing provides high mounting flexibility and the ability to standardize and reduce the variety of bearing housings.

Bearing housing for axial load

If high axial forces occur, MISUMI offers a special form of flange bearings in the combination of needle bearings for radial forces and axial ball bearings for axial forces.

Maintenance

For bearing housings, the installed bearing can be replaced after the service life has been reached. If the bearings are pressed into the bearing housing, it is recommended to replace the bearing together with the housing. The bearing number installed in the MISUMI bearing housing is discernible from the article number of the bearing unit.

Further information about the various application of bearings can be found under the tab More Information.

Note : After determining the bearing number, you can enter it in the search window to determine the load values and specifications of the bearing for the calculation.

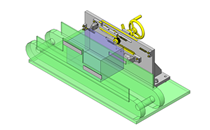

Application example of a flange bearing housing

(1) Collar, (2) Bearing lock nut, (3) Deep groove ball bearing, (4) Housing, (5) Rotary shaft, (6) O-ring, (7) Angular ball bearing, (8) Collar

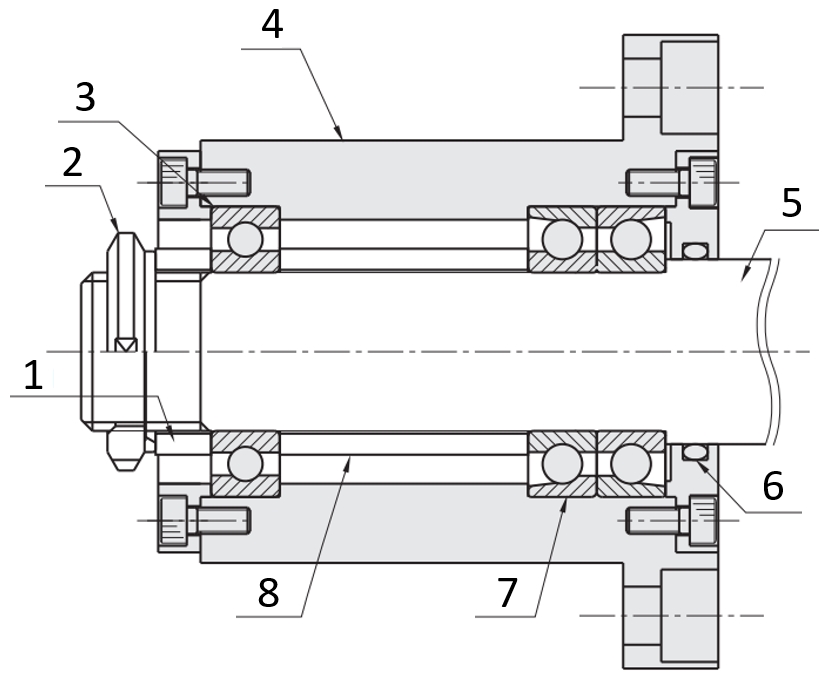

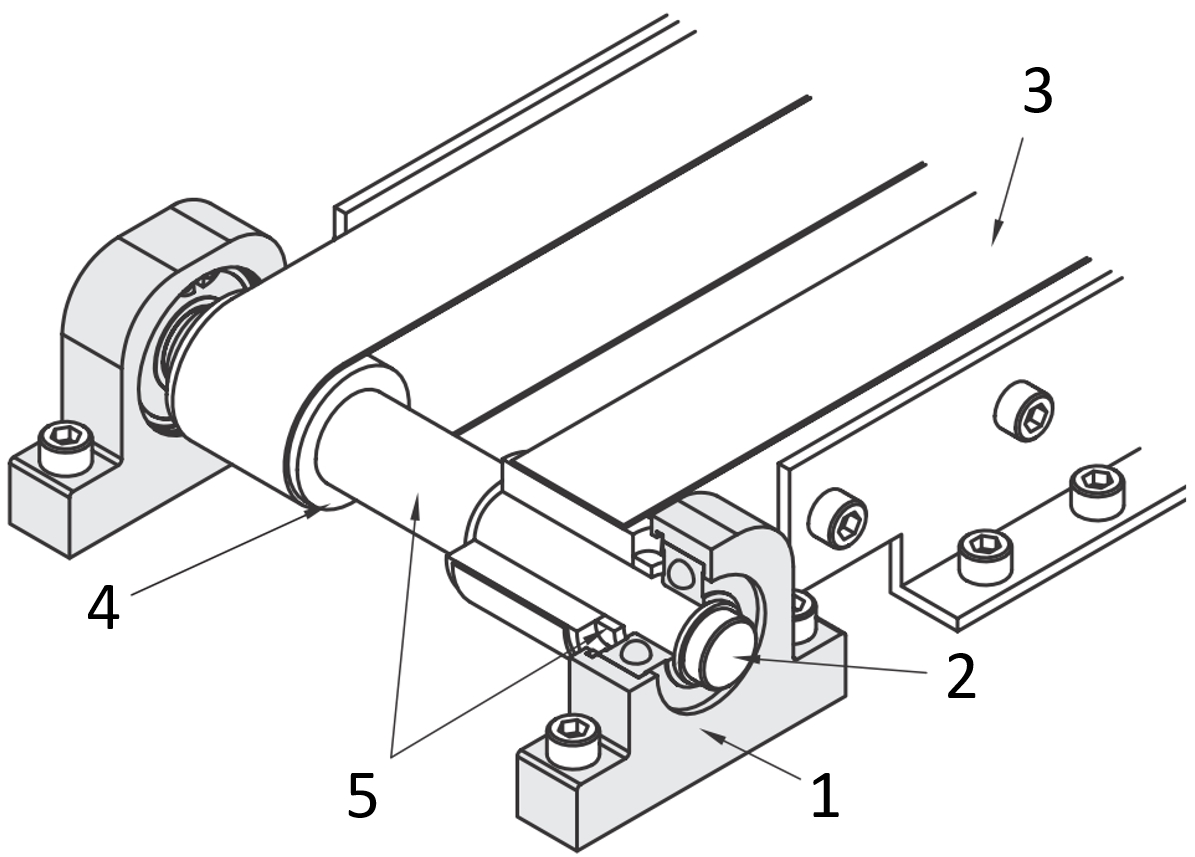

Application example of a pedestal bearing with conveyor belt

(1) Pedestal bearing, (2) Rotary shaft, (3) Conveyor belt, (4) Idler for flat belts, (5) Collar

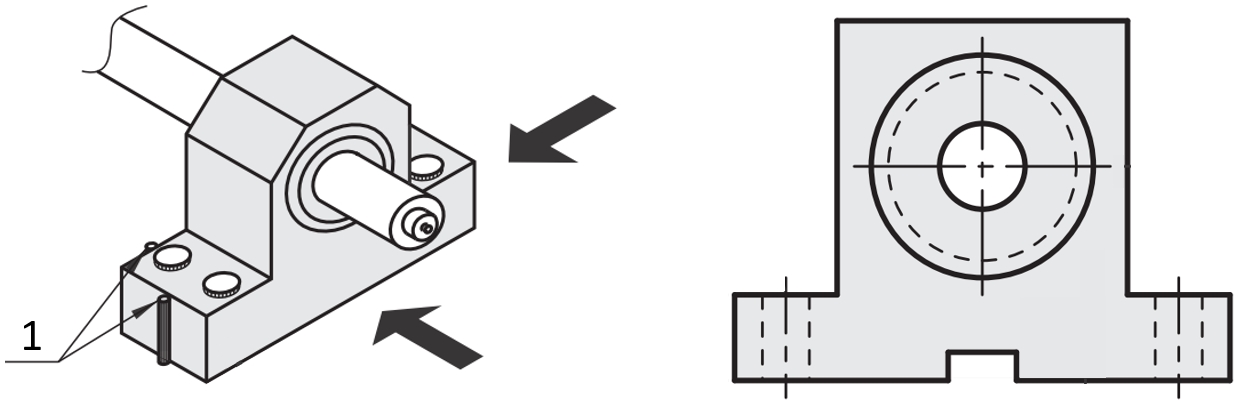

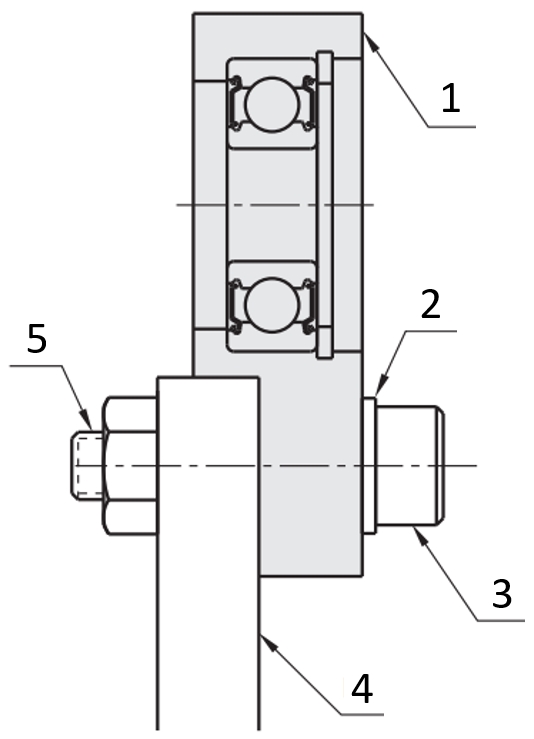

Application example of a bearing housing

(1) Bearing housing, (2) Metal washer, (3) Screw, (4) Mounting plate, (5) Nut

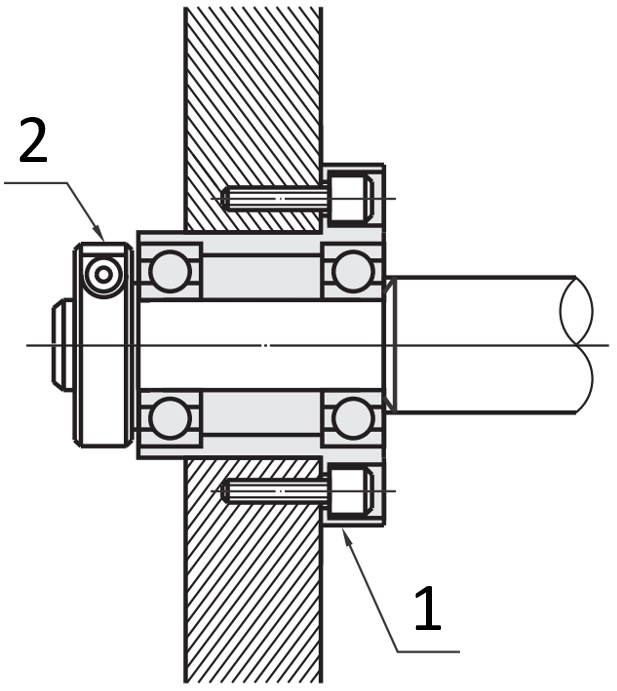

Application example of a flange bearing housing with clamping ring

(1) Flange bearing, (2) Clamping ring

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Bearing I.D. d (mm) | Bearing Material | Holder Material | Flange Shape | Thickness T (mm) | Holder Surface Treatment | Bearing Part Number | Seals | Flange Outer Dia. H (Ø) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6000 | DD (Contact Rubber Seal) | 50 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6000 | VV (Non-Contact Rubber Seal) | 50 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6000 | ZZ (Double Shield) | 50 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6001 | DD (Contact Rubber Seal) | 52 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6001 | VV (Non-Contact Rubber Seal) | 52 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 40 | Clear Anodize | 6001 | ZZ (Double Shield) | 52 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 50 | Clear Anodize | 6002 | DD (Contact Rubber Seal) | 60 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 50 | Clear Anodize | 6002 | VV (Non-Contact Rubber Seal) | 60 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 50 | Clear Anodize | 6002 | ZZ (Double Shield) | 60 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6003 | DD (Contact Rubber Seal) | 66 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6003 | VV (Non-Contact Rubber Seal) | 66 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6003 | ZZ (Double Shield) | 66 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6004 | DD (Contact Rubber Seal) | 77 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6004 | VV (Non-Contact Rubber Seal) | 77 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6004 | ZZ (Double Shield) | 77 | ||

- | 1 | 10 Days | 10 | 5 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 35 | Clear Anodize | 605 | DD (Contact Rubber Seal) | 36 | ||

- | 1 | 10 Days | 10 | 5 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 605 | ZZ (Double Shield) | 36 | ||

- | 1 | 10 Days | 10 | 6 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 35 | Clear Anodize | 606 | DD (Contact Rubber Seal) | 39 | ||

- | 1 | 10 Days | 10 | 6 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 35 | Clear Anodize | 606 | ZZ (Double Shield) | 39 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 608 | DD (Contact Rubber Seal) | 45 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 608 | VV (Non-Contact Rubber Seal) | 45 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 608 | ZZ (Double Shield) | 45 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6200 | DD (Contact Rubber Seal) | 54 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6200 | VV (Non-Contact Rubber Seal) | 54 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6200 | ZZ (Double Shield) | 54 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6201 | DD (Contact Rubber Seal) | 56 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6201 | VV (Non-Contact Rubber Seal) | 56 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6201 | ZZ (Double Shield) | 56 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6202 | DD (Contact Rubber Seal) | 64 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6202 | VV (Non-Contact Rubber Seal) | 64 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 35 ~ 50 | Clear Anodize | 6202 | ZZ (Double Shield) | 64 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6203 | DD (Contact Rubber Seal) | 72 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6203 | VV (Non-Contact Rubber Seal) | 72 | ||

- | 1 | 10 Days | 10 | 17 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 40 ~ 50 | Clear Anodize | 6203 | ZZ (Double Shield) | 72 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 45 ~ 50 | Clear Anodize | 6204 | DD (Contact Rubber Seal) | 81 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 45 ~ 50 | Clear Anodize | 6204 | VV (Non-Contact Rubber Seal) | 81 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 45 ~ 50 | Clear Anodize | 6204 | ZZ (Double Shield) | 81 | ||

- | 1 | 10 Days | 10 | 3 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 623 | DD (Contact Rubber Seal) | 33 | ||

- | 1 | 10 Days | 10 | 3 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 623 | ZZ (Double Shield) | 33 | ||

- | 1 | 10 Days | 10 | 4 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 624 | DD (Contact Rubber Seal) | 35 | ||

- | 1 | 10 Days | 10 | 4 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 624 | ZZ (Double Shield) | 35 | ||

- | 1 | 10 Days | 10 | 5 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 30 | Clear Anodize | 625 | DD (Contact Rubber Seal) | 38 | ||

- | 1 | 10 Days | 10 | 5 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 30 | Clear Anodize | 625 | VV (Non-Contact Rubber Seal) | 38 | ||

- | 1 | 10 Days | 10 | 5 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 30 | Clear Anodize | 625 | ZZ (Double Shield) | 38 | ||

- | 1 | 10 Days | 10 | 6 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 626 | VV (Non-Contact Rubber Seal) | 41 | ||

- | 1 | 10 Days | 10 | 6 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 626 | ZZ (Double Shield) | 41 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 628 | DD (Contact Rubber Seal) | 47 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 628 | VV (Non-Contact Rubber Seal) | 47 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 628 | ZZ (Double Shield) | 47 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 6700 | DD (Contact Rubber Seal) | 37 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 6700 | ZZ (Double Shield) | 37 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 6701 | DD (Contact Rubber Seal) | 40 | ||

- | 1 | 10 Days | 10 | 12 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 6701 | ZZ (Double Shield) | 40 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 6702 | DD (Contact Rubber Seal) | 44 | ||

- | 1 | 10 Days | 10 | 15 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 25 ~ 35 | Clear Anodize | 6702 | ZZ (Double Shield) | 44 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6704 | DD (Contact Rubber Seal) | 51 | ||

- | 1 | 10 Days | 10 | 20 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 30 ~ 40 | Clear Anodize | 6704 | ZZ (Double Shield) | 51 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 678 | DD (Contact Rubber Seal) | 34 | ||

- | 1 | 10 Days | 10 | 8 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 678 | ZZ (Double Shield) | 34 | ||

- | 1 | 10 Days | 10 | 10 | [Steel] Steel | [EN AW-2017 Equiv.] Aluminum Alloy 2000 series | Compact Type | 20 ~ 30 | Clear Anodize | 6800 | DD (Contact Rubber Seal) | 41 |

Loading...

Back to the Category Bearings with Housing

| Part Number | L Selection | d | DH7 | B | H | W | T | dh | D1g7 | P.C.D. | K | A | F | d1 | d2 | H1 | |||||

| Type | Bearing No. | Seal | Tolerance | Tolerance | |||||||||||||||||

| (Round) BGRCB BGRC BARC SBARC SBGRC (Square) BGSCB BGSC BASC SBASC SBGSC (Compact) BGCCB BGCC BACC SBACC SBGCC | 623 | ZZ Double Shielded *1 *2VV Non-Contact Sealed Rubber Seal *2DD Contact Sealed Rubber Seal | 20 | 30 | 3 | 10 | + 0.015 0 | 4 | 33 | 16 | 7 | 7 | 14 | -0.006 -0.024 | 24 | 27 | 24 | - | 6.5 | 3.5 | 3.1 |

| 624 | 20 | 30 | 4 | 13 | + 0.018 0 | 5 | 35 | 18 | 9 | 17 | 26 | 28 | 26 | ||||||||

| 605 | 20 | 30 | 5 | 14 | 5 | 36 | 20 | 8 | 10 | 18 | 26 | 30 | 26 | 8 | 4.5 | 4.1 | |||||

| 625 | 25 | 30 | 16 | 5 | 38 | 22 | 12 | 20 | -0.007 -0.028 | 28 | 31 | 28 | |||||||||

| 606 | 20 | 35 | 6 | 17 | 6 | 39 | 23 | 13 | 21 | 29 | 32 | 29 | |||||||||

| 626 | 25 | 35 | 19 | + 0.021 0 | 6 | 41 | 25 | 15 | 24 | 31 | 34 | 31 | |||||||||

| 678 | 20 | 30 | 8 | 12 | + 0.018 0 | 3.5 | 34 | 18 | 10 | 16 | -0.006 -0.024 | 25 | 27 | 25 | 6.5 | 3.5 | 3.1 | ||||

| 698 | 25 | 35 | 19 | + 0.021 0 | 6 | 41 | 25 | 15 | 24 | -0.007 -0.028 | 31 | 34 | 31 | 8 | 4.5 | 4.1 | |||||

| 608 | 25 | 35 | 22 | 7 | 45 | 29 | 18 | 27 | 35 | 36 | 35 | ||||||||||

| 628 | 25 | 35 | 24 | 8 | 47 | 32 | 20 | 30 | 37 | 37 | 37 | ||||||||||

| 6700 | 20 | 30 | 10 | 15 | + 0.018 0 | 4 | 37 | 22 | 12 | 19 | 27 | 30 | 27 | ||||||||

| 6800 | 20 | 30 | 19 | + 0.021 0 | 5 | 41 | 25 | 15 | 24 | 31 | 34 | 31 | |||||||||

| 6900 | 25 | 40 | 22 | 6 | 45 | 29 | 19 | 27 | 35 | 36 | 35 | ||||||||||

| 6000 | 25 | 40 | 26 | 8 | 50 | 34 | 22 | 32 | -0.009 -0.034 | 40 | 39 | 40 | |||||||||

| 6200 | 30 | 40 | 30 | 9 | 54 | 38 | 24 | 36 | 44 | 42 | 44 | ||||||||||

| 6701 | 20 | 30 | 12 | 18 | + 0.018 0 | 4 | 40 | 25 | 15 | 23 | -0.007 -0.028 | 30 | 31 | 30 | |||||||

| 6801 | 25 | 35 | 21 | + 0.021 0 | 5 | 44 | 29 | 17 | 26 | 34 | 35 | 34 | |||||||||

| 6901 | 25 | 40 | 24 | 6 | 48 | 31 | 21 | 30 | 38 | 38 | 38 | ||||||||||

| 6001 | 25 | 40 | 28 | 8 | 52 | 36 | 24 | 34 | -0.009 -0.034 | 42 | 40 | 42 | |||||||||

| 6201 | 30 | 40 | 32 | + 0.025 0 | 10 | 56 | 40 | 26 | 38 | 46 | 43 | 46 | |||||||||

| 6702 | 25 | 35 | 15 | 21 | + 0.021 0 | 4 | 44 | 29 | 18 | 26 | -0.007 -0.028 | 34 | 35 | 34 | |||||||

| 6802 | 25 | 35 | 24 | 5 | 47 | 32 | 20 | 30 | 37 | 37 | 37 | ||||||||||

| 6902 | 25 | 50 | 28 | 7 | 57 | 37 | 10 | 25 | 35 | -0.009 -0.034 | 45 | 45 | 45 | 9.5 | 5.5 | 5.1 | |||||

| 6002 | 30 | 50 | 32 | + 0.025 0 | 9 | 60 | 40 | 28 | 38 | 48 | 46 | 48 | |||||||||

| 6202 | 35 | 50 | 35 | 11 | 64 | 44 | 29 | 42 | 52 | 49 | 52 | ||||||||||

| 6803 | 30 | 40 | 17 | 26 | + 0.021 0 | 5 | 50 | 34 | 22 | 32 | 40 | 39 | 40 | 8 | 4.5 | 4.1 | |||||

| 6903 | 30 | 40 | 30 | 7 | 60 | 38 | 27 | 36 | 48 | 46 | 48 | 9.5 | 5.5 | 5.1 | |||||||

| 6003 | 35 | 50 | 35 | + 0.025 0 | 10 | 66 | 44 | 31 | 42 | 54 | 50 | 54 | |||||||||

| 6203 | 40 | 50 | 40 | 12 | 72 | 50 | 34 | 48 | 60 | 54 | 60 | ||||||||||

| 6704 | 30 | 40 | 20 | 27 | + 0.021 0 | 4 | 51 | 35 | 23 | 33 | 41 | 39 | 32 | 25 | 8 | 4.5 | 4.1 | ||||

| 6804 | 35 | 50 | 32 | + 0.025 0 | 7 | 60 | 40 | 28 | 38 | 48 | 46 | 38 | 29 | 9.5 | 5.5 | 5.1 | |||||

| 6904 | 35 | 50 | 37 | 9 | 69 | 47 | 11 | 34 | 45 | 56 | 54 | 51 | 24 | 11 | 6.6 | 6.1 | |||||

| 6004 | 40 | 50 | 42 | 12 | 77 | 54 | 36 | 50 | 64 | 59 | 56 | 32 | |||||||||

| 6204 | 45 | 50 | 47 | 14 | 81 | 58 | 40 | 54 | -0.010 -0.040 | 68 | 62 | 59 | 34 | ||||||||

| 6805 | 35 | 50 | 25 | 37 | 7 | 69 | 47 | 34 | 45 | -0.009 -0.034 | 56 | 54 | 51 | 24 | |||||||

| 6905 | 35 | 50 | 42 | 9 | 77 | 54 | 36 | 50 | 64 | 59 | 56 | 32 | |||||||||

| 6005 | 40 | 60 | 47 | 12 | 88 | 58 | 13 | 41 | 54 | -0.010 -0.040 | 72 | 67 | 63 | 36 | 14 | 9 | 8.1 | ||||

| 6205 | 45 | 60 | 52 | + 0.030 0 | 15 | 94 | 64 | 45 | 60 | 78 | 72 | 68 | 39 | ||||||||

| 6806 | 35 | 50 | 30 | 42 | + 0.025 0 | 7 | 77 | 54 | 36 | 50 | -0.009 -0.034 | 64 | 59 | 56 | 32 | 11 | 6.6 | 6.1 | |||

| 6906 | 35 | 50 | 47 | 9 | 88 | 58 | 41 | 54 | -0.010 -0.040 | 72 | 67 | 63 | 36 | 14 | 9 | 8.1 | |||||

| 6006 | 40 | 60 | 55 | + 0.030 0 | 13 | 96 | 66 | 48 | 62 | 80 | 73 | 70 | 40 | ||||||||

| 6206 | 50 | 60 | 62 | 16 | 104 | 74 | 55 | 70 | 88 | 79 | 77 | 44 | |||||||||

| 6007 | 50 | 60 | 35 | 62 | 14 | 104 | 74 | 55 | 70 | 88 | 79 | 75 | 44 | ||||||||

| 6207 | 60 | 80 | 72 | 17 | 126 | 88 | 20 | 64 | 84 | -0.012 -0.047 | 105 | 95 | 92 | 51 | 17.5 | 11 | 11 | ||||

| 6008 | 60 | 70 | 40 | 68 | 15 | 114 | 82 | 13 | 60 | 78 | -0.010 -0.040 | 96 | 86 | 80 | 54 | 14 | 9 | 8.1 | |||

| 6208 | 60 | 80 | 80 | 18 | 134 | 96 | 20 | 74 | 92 | -0.012 -0.047 | 113 | 102 | 98 | 56 | 17.5 | 11 | 11 | ||||

| 6010 | ZZ Double Shielded | 70 | 50 | 80 | 16 | 134 | 96 | 74 | 92 | 113 | - | 98 | 56 | ||||||||

| 6210 | 90 | 90 | + 0.035 0 | 20 | 147 | 110 | 83 | 106 | 126 | - | 104 | 72 | |||||||||

*1 No. 623, 624, 605, 606 and numbers starting with 67 are not available for VV (Non-contact Sealed).

*2 Bearings with Rubber Seals are all made of steel.

Basic information

| Shape | Flange Type | Bearing Used | Deep Groove Ball Bearings | Number of Bearings | Double |

|---|---|---|---|---|---|

| Retaining Ring | Not Provided | Type | Bearings with Housings |

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Bearing I.D. d(mm)

-

Bearing Material

- Steel

- Stainless Steel

- Steel

-

Holder Material

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

- EN AW-2017 Equiv.

-

Flange Shape

- Round Type

- Square Type

- Compact Type

-

Thickness T(mm)

-

Holder Surface Treatment

- Black Oxide

- Electroless Nickel Plating

- Clear Anodize

- Not Provided

-

Bearing Part Number

-

Seals

- DD (Contact Rubber Seal)

- VV (Non-Contact Rubber Seal)

- ZZ (Double Shield)

-

Flange Outer Dia. H(Ø)

-

Type

- BACC

- BARC

- BASC

- BGCC

- BGCCB

- BGRC

- BGRCB

- BGSC

- BGSCB

- SBACC

- SBARC

- SBASC

- SBGCC

- SBGRC

- SBGSC

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 6 Days or Less

- 10 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry