- inCAD Library Home

- > No.000177 Gripper that reverses and rotates

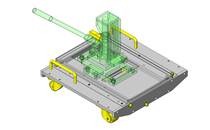

No.000177 Gripper that reverses and rotates

70

70

Reverse gripper

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

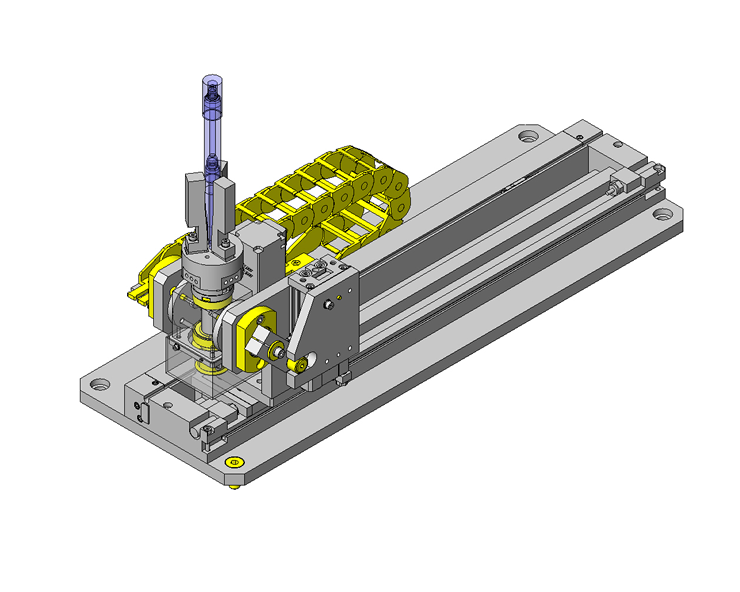

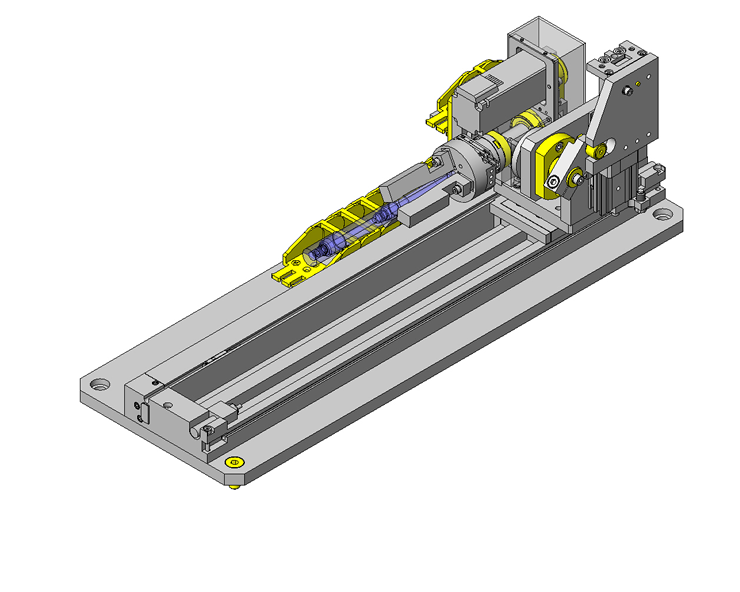

- Gripper reverses and rotates the workpiece as the workpiece is laser engraved.

- Operation

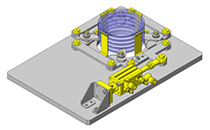

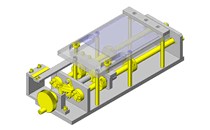

- Workpieces are transported to the receiving/discharging position by a robot. Once the workpiece is in place, the three-claw pneumatic gripper reverses the part 90° and moves forward into printing position. As the piece is being laser marked, a stepper motor and timing belt rotates the workpiece. When printing is completed, the gripper reverses back 90° into receiving/discharging position and the piece is removed by a robot.

Target workpiece

- Shape: Bar-shape

- Workpiece size: Ø12 x L145mm

- Weight: 37g

Design Specifications

Operating Conditions or Design Requirements

- Stroke of the three-claw pneumatic gripper: 6mm

- Reversing angle: 90°

- Rotation angle: 90°

- External size: W460 x D165 x H230mm

Required Performance

- Position repeatability accuracy of the three-claw pneumatic gripper: ±0.1mm

Design Evaluation

Verification of main components

- Verify the gripping force of the pneumatic gripper for appropriate workpiece gripping force.

- Check the gripping force of the three-claw pneumatic gripper

- Conditional values: Center of gravity of workpiece L1 = 85mm, workpiece gripping point L2 = 59.5mm, workpiece weight m = 37g, supply pressure p = 0.5MPa, gravitational acceleration g = 9.8m/s², friction coefficient µ = 0.2 (metal vs. metal)

- Gripping force F1 of the three-claw pneumatic gripper at supply pressure p, and workpiece gripping point L2 is obtained form the graph as F1 = 4.5N.

Gripping force on the workpiece F1' = F1 x µ Thus, F1' = 4.5 x 0.2 = 0.9N - Required gripping force F2 is obtained from the balance of the moment as follows.

Mg x L1 = F2 x L2

F2 = Mg x (L1 / L2) Thus, F2 = 37 x 10⁻³ x 9.8 x (85 / 59.5) = 0.518N

F1' > F2 Thus, sufficient gripping force is achieved.

Other Design Consideration

- Install a mechanical stopper to limit the rotation of the three-claw pneumatic gripper below 270°. This stopper serves as a countermeasure against cable entanglement and disconnection.

- For safety purposes, a cover is installed over the timing belt.

Explore Similar Application Examples

Page

-

/

-