stopper bolts / external hexagon socket, internal hexagon socket / fine thread, regular thread / stop face at head / material selectable / treatment selectable / 40-45 HRC (Part Numbers - CAD Download)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

Back to the Category Stopper Bolts

Technical Drawing - Stopper Bolts

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Stopper Bolts

| Stopper Bolts | Type | Material | Hardness | Surface Treatment | |

| Standard | Hex Socket | ||||

| Fine | STRCB | STRCC | EN 1.7220 Equiv. | 40~45HRC | Black Oxide |

| STRCN | STRNCC | Electroless Nickel Plating | |||

| SSTRCB | SSTRCC | EN 1.4006 Equiv. | - | ||

| Coarse | STRB | STRC | EN 1.7220 Equiv. | Black Oxide | |

| STRN | STRNC | Electroless Nickel Plating | |||

| SSTRB | SSTRC | EN 1.4006 Equiv. | - | ||

Composition of a Product Code - Stopper Bolts

| Part Number | - | L |

| STRB6 | - | 20 |

Alterations - Stopper Bolts

General Information - Stopper Bolts

Stopper bolts selection details

- Material: steel, stainless steel

- Baffle head: PU, POM, MC nylon, silicone, hard rubber

- Coatings: burnished, chrome-plated, nickel-plated, zinc-plated

- Strength class: 8.8, 10.9

- Hardness of baffle head: Shore A57, Shore A70, Shore A90

- Thread diameter: M3 to M16

- Length: 10 mm to 70 mm

Description/Basics

MISUMI stopper bolts are generally used as damped and undamped stops for components and applications in mechanical engineering.

Undamped stopper bolts are protected against premature wear with hardened tips or heads. However, undamped stopper bolts may damage component surfaces. To protect the components to be stopped, a damped stopper bolt may protect the surface against damage with a rubber or plastic baffle head. In addition, MISUMI offers a stopper bolt with rubber or hard rubber in different Shore hardnesses, which can dampen the impact and reduce vibrations.

In addition to the standard threads, MISUMI also offers the stopper bolts with fine threads. The stopper bolts with fine threads enable finer adjustments compared to standard threads.

MISUMI offers Threaded Stopper Blocks as suitable and robust fastening for the assembly of the stopper bolts.

The stopper bolt can serve as a stop protection for workpiece carriers in order to protect them from damage. A stopper bolt with rubber can also reduce vibrations and oscillations to protect the goods to be transported. Often, stopper bolts are combined with industrial adjustable shock absorbers as end position damping to protect the damper from a hard end stop.

The stopper boltcan also be used alternatively in clamp.

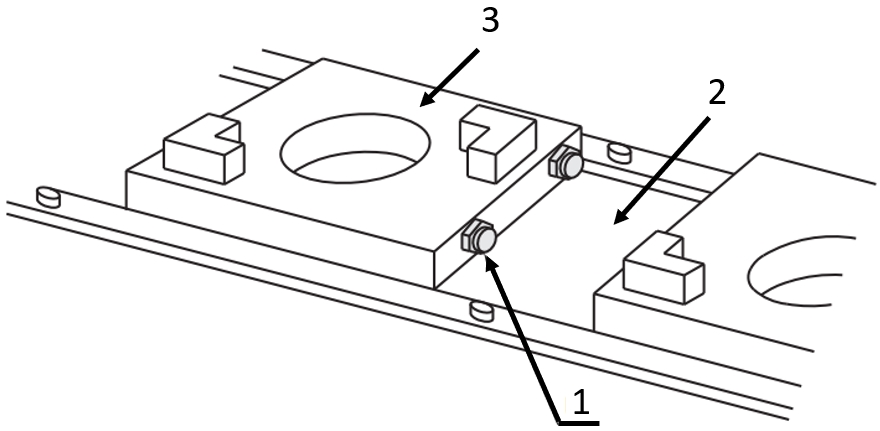

Application Examples - Stopper Bolts

Application example: workpiece carrier

(1) Stopper bolt with rubber, (2) belt conveyor, (3) workpiece carrier

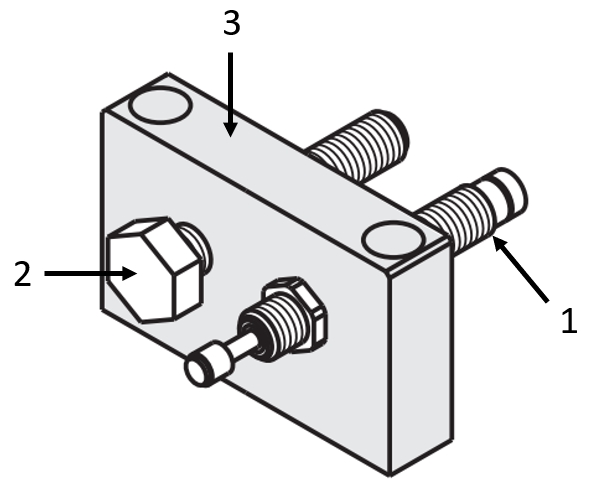

Application example: end stop

(1) Adjustable shock absorber, (2) Stopper bolt, (3) Threaded stopper blocks

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Tip Shape | Screw Material | Screw Surface Treatment | Thread Dia. M | Thread Pitch (mm) | L (mm) | Alterations:Change L Dimension Configurable 1mm Increment [LC] (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 12 | 1.75 (Coarse) | 35 ~ 80 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 12 | 1.75 (Coarse) | - | 35 ~ 80 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 4 | 0.7 (Coarse) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 4 | 0.7 (Coarse) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 5 | 0.8 (Coarse) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 5 | 0.8 (Coarse) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 6 | 1.0 (Coarse) | 20 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 6 | 1.0 (Coarse) | - | 20 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 8 | 1.25 (Coarse) | 25 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 8 | 1.25 (Coarse) | - | 25 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 10 | 1.5 (Coarse) | 30 ~ 70 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 10 | 1.5 (Coarse) | - | 30 ~ 70 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 12 | 1.75 (Coarse) | 35 ~ 80 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 12 | 1.75 (Coarse) | - | 35 ~ 80 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 4 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 4 | 0.5 (Fine) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 5 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 5 | 0.5 (Fine) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 6 | 0.75 (Fine) | 20 ~ 60 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 6 | 0.75 (Fine) | - | 20 ~ 60 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 8 | 0.75 (Fine) | 25 ~ 60 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 8 | 0.75 (Fine) | - | 25 ~ 60 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 10 | 1.0 (Fine) | 30 ~ 70 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 10 | 1.0 (Fine) | - | 30 ~ 70 | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 12 | 1.0 (Fine) | 35 ~ 80 | - | ||

- | 1 | 6 Days | 10 | Standard | EN 1.7220 Equiv. | Black Oxide | 12 | 1.0 (Fine) | - | 35 ~ 80 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 4 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 4 | 0.5 (Fine) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 5 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 5 | 0.5 (Fine) | - | 15 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 6 | 0.75 (Fine) | 20 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 6 | 0.75 (Fine) | - | 20 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 8 | 0.75 (Fine) | 25 ~ 60 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 8 | 0.75 (Fine) | - | 25 ~ 60 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 10 | 1.0 (Fine) | 30 ~ 70 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 10 | 1.0 (Fine) | - | 30 ~ 70 | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 12 | 1.0 (Fine) | 35 ~ 80 | - | ||

- | 1 | 6 Days | 10 | With Hex Socket | EN 1.7220 Equiv. | Black Oxide | 12 | 1.0 (Fine) | - | 35 ~ 80 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 4 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 4 | 0.5 (Fine) | - | 15.1 ~ 59.1 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 5 | 0.5 (Fine) | 15 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 5 | 0.5 (Fine) | - | 16 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 6 | 0.75 (Fine) | 20 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 6 | 0.75 (Fine) | - | 21 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 8 | 0.75 (Fine) | 25 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 8 | 0.75 (Fine) | - | 26 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 10 | 1.0 (Fine) | 30 ~ 70 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 10 | 1.0 (Fine) | - | 31 ~ 69 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 12 | 1.0 (Fine) | 35 ~ 80 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 12 | 1.0 (Fine) | - | 35 ~ 80 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 3 | 0.5 (Coarse) | 10 ~ 30 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 3 | 0.5 (Coarse) | - | 11 ~ 29 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 4 | 0.7 (Coarse) | 15 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 4 | 0.7 (Coarse) | - | 16 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 5 | 0.8 (Coarse) | 15 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 5 | 0.8 (Coarse) | - | 16 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 6 | 1.0 (Coarse) | 20 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 6 | 1.0 (Coarse) | - | 21 ~ 59 | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 8 | 1.25 (Coarse) | 25 ~ 60 | - | ||

- | 1 | 9 Days | 10 | Standard | EN 1.7220 Equiv. | Electroless Nickel Plating | 8 | 1.25 (Coarse) | - | 26 ~ 59 |

Loading...

Back to the Category Stopper Bolts

Technical Drawing - Stopper Bolts

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More Information.

Specification Tables - Stopper Bolts

| Part Number | L 5mm Increment | M | B | (C) | H | ( ℓ ) | (r) | ℓ 1 | B1 | Unit Price | ||||||||||

| Type | M | Coarse | Fine | STRCB STRB | STRCN STRN | SSTRCB SSTRB | STRCC STRC | STRNCC STRNC | SSTRCC SSTRC | |||||||||||

| Standard | Hex Socket Type | *3 | 10~30 | 3x0.5 | - | 5.5 | 6.4 | 2 | 1 | 0.1 | - | - | - | - | - | - | ||||

| 4 | 15~60 | 4x0.7 | 4x0.5 | 7 | 8.1 | 2.8 | 2.1 | 0.2 | 2.2 | 2 | ||||||||||

| (Fine) STRCB STRCN SSTRCB | (Coarse) STRB STRN SSTRB | (Fine) STRCC STRNCC SSTRCC | (Coarse) STRC STRNC SSTRC | 5 | 15~60 | 5x0.8 | 5x0.5 | 8 | 9.2 | 3.5 | 2.4 | 2.8 | 2.5 | |||||||

| 6 | 20~60 | 6x1.0 | 6x0.75 | 10 | 11.5 | 4 | 3 | 0.3 | 3 | 3 | ||||||||||

| 8 | 25~60 | 8x1.25 | 8x0.75 | 13 | 15.0 | 5.5 | 3.7 | 0.4 | 4 | 4 | ||||||||||

| 10 | 30~70 | 10x1.5 | 10x1.0 | 17 | 19.6 | 7 | 4.5 | 0.5 | 5 | 5 | ||||||||||

| 12 | 35~80 | 12x1.75 | 12x1.0 | 19 | 21.9 | 8 | 5.2 | 6 | 6 | |||||||||||

Alterations - Stopper Bolts

Configure

Basic Attributes

-

Tip Shape

- Standard

- With Hex Socket

-

Screw Material

- EN 1.4006 Equiv.

- EN 1.7220 Equiv.

-

Screw Surface Treatment

- Black Oxide

- Electroless Nickel Plating

- Not Provided

-

Thread Dia. M

- 3

- 4

- 5

- 6

- 8

- 10

- 12

-

Thread Pitch(mm)

-

L(mm)

-

Alterations:Change L Dimension Configurable 1mm Increment [LC](mm)

-

Type

- SSTRB

- SSTRC

- SSTRCB

- SSTRCC

- STRB

- STRC

- STRCB

- STRCC

- STRCN

- STRN

- STRNC

- STRNCC

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 6 Days or Less

- 9 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Why do stopper bolts come in different colours?

-

Answer:

The stopper bolt may have a different colouration. The reason for this is the hardening of the usable area, such as tip or head. Since the hardening is not necessary on the complete stopper bolt, it may show a colour gradient.

-

Question:

Can a stopper bolt be installed with an angle?

-

Answer:

The stopper bolt can be fastened with a mounting bracket for smaller loads. A more robust mounting bracket should be used for higher loads and an expected impact. MISUMI offers suitable brackets for stopper bolts.

-

Question:

Are stopper bolts suitable for lateral impact?

-

Answer:

Not every stopper bolt is intended for lateral stop. This could damage the stopper bolt. stopper bolts with rubber or plastic tip could lose the damping material. For a lateral stop, stopper bolts are self-adjusting, which MISUMI has also available in various materials and damping materials.

MISUMI has a corresponding note on the technical drawing of stopper bolts that may not be used on the side. -

Question:

Can a stopper bolt dampen vibrations?

-

Answer:

A stopper bolt with a hard rubber tip is suitable for good vibration damping. Hard rubber is very low-return and absorbs more than conventional rubber, oscillations and vibrations. In addition, the oscillation amplitude is significantly shortened. If strong vibrations occur, a vibration damper can be used.

-

Question:

What are PU stopper bolts resistant to?

-

Answer:

Stopper bolts with polyurethane rubber (PU) have high mechanical strength and abrasion resistance. Any additional resistance of the rubber depends on whether it is an ether or ester polyurethane. This can be found in the PDF Properties of Polyurethane.

-

Question:

How high is the heat resistance of the polyurethane rubber of the stopper bolt?

-

Answer:

The stopper bolt with polyurethane rubber as a damping material should not be used at over ~+70°C. There is a risk that the material will deform plastically and the stopper bolt will fatigue prematurely.

-

Question:

What can be used as a counter stop of a stopper bolt?

-

Answer:

A stopper bolt can serve as a counter stop for a stopper bolt. These are hardened and therefore very low-wear. They can be pressed in or screwed together for ease of maintenance.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)