- inCAD Library Home

- > No.000284 Simultaneous Two-Hand Pushbutton Switch Mechanism

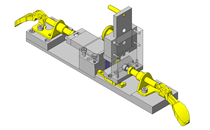

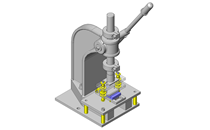

No.000284 Simultaneous Two-Hand Pushbutton Switch Mechanism

14

14

Starts with the simultaneous pressing of switches.

Related Category

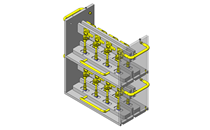

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- A semi-automatic mechanism that descends the cylinders as the right and left switches are simultaneously pressed and press-fits workpieces together.

- Pressing either one of the right and left switches does not move the cylinders.

- A mechanism in which the cylinders stop and ascend when the right or left hand is released while the cylinders are descending.

Points for use

- The worker would need to press the right and left switches simultaneously to start the machine.

- Prevents the pinching and entanglement of workers.

Target workpiece

- Whole workpiece

- Material: resin case (press-fit process)

- Cap

- Dimensions: Ø30 x 6.5mm

- Mass: approx. 3g

- Case

- Dimensions: Ø30 x 26.5mm

- Mass: approx. 9g

Design Specifications

Operating Conditions or Design Requirements

- Operational Specifications

- Maximum cylinder setting stroke: 95mm

- Outer dimensions

- W480 x D300 x H353mm

Required Performance

- Cylinder thrust

- Cylinder thrust required for press-fitting workpiece: 50N or above

Selection Criteria for Main Components

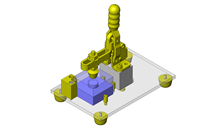

- Air cylinder

- A cylinder with a guide is selected for space-saving purposes.

Design Evaluation

Verification of main components

- The cylinder thrust is verified to see whether the required press-fitting force is satisfied.

- Cylinder capacity

- From setting air pressure: 0.2MPa and cylinder inner diameter: 25mm, cylinder thrust on pushing side: F0 = 63N (from catalog)

- Required press-fitting force: F1 = 50N * The press-fitting force is checked using measurement instruments before design.

- Safety factor: F0/F1 = 63/50 = 1.26 * Air pressure is adjusted to 0.2MPa and can be set up to 0.5MPa.

- When air pressure is 0.5MPa, cylinder thrust on pushing side: F2 = 157N (from catalog)

- Safety factor: F2/F1 = 157/50 = 3.14

* The force that breaks the workpiece is 250N or higher.

Other Design Consideration

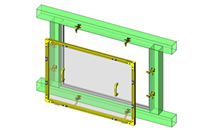

- An area sensor is not necessary due to the installation of cover. Access path is limited to the worker side.

Explore Similar Application Examples

Page

-

/

-