- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 3:00 26/5/2024 to 1:00 (CET) 27/5/2024. We apologize for the inconvenience.

Locating pins, Centring pins / selectable head shape / round head / selectable mounting variant (Part Numbers - CAD Download)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

| Material No. | Material | Surface Treatment | Hardness | Type | Shape Code | ||

| Press Fit | Tapped | Threaded | |||||

| EN 1.2510 Equiv. | - | Treated Hardness: 60 ~ 63HRC | KFQ | KFQT | KFQN | A (Round) D (Diamond) | |

| EN 1.2510 Equiv. | Hard Chrome Plating | Treated Hardness: 50 ~ 55HRC Plating Hardness: 750HV ~ | GKFQ | GKFQT | GKFQN | ||

| EN 1.4301 Equiv. | - | - | SKFQ | SKFQT (Round only) | SKFQN | ||

| EN 1.4301 Equiv. | Hard Chrome Plating | Plating Hardness: 750HV ~ | HKFQ | - | - | ||

| EN 1.4037 Equiv. | - | Treated Hardness: 50 ~ 55HRC | CKFQ | CKFQT (Round only) | CKFQN | ||

| EN 1.2510 Equiv. | Buffing | Treated Hardness: 60 ~ 63HRC | MKFQ | - | - | ||

| EN 1.2510 Equiv. | Hard Chrome Plating + Buffed | Treated Hardness: 50 ~ 55HRC Plating Hardness: 750HV ~ | MGKFQ | MGKFQT | MGKFQN | ||

| EN 1.4037 Equiv. | Buffing | Treated Hardness: 50 ~ 55HRC | - | MCKFQT | - | ||

Specifications

| Part Number | - | P | - | L | - | B | ||||||||

| Type | Shape | D Tol. | P Tolerance | D | ||||||||||

| KFQ | A | M | S | 6 | - | P8.00 | - | L8 | - | B6.0 | ||||

| D or P | Standard Grade | Precision Grade | |||||

| M | P | G | H | S | A | B | |

| m6 | p6 | g6 | h7 | - | - | - | |

| 1.00 ~ 3.00 | +0.008 +0.002 | +0.012 +0.006 | -0.002 -0.008 | 0 -0.010 | 0 -0.01 | +0.005 0 | 0 -0.005 |

| 3.01 ~ 6.00 | +0.012 +0.004 | +0.020 +0.012 | -0.004 -0.012 | 0 -0.012 | |||

| 6.01 ~ 10.00 | +0.015 +0.006 | +0.024 +0.015 | -0.005 -0.014 | 0 -0.015 | |||

| 10.01 ~ 18.00 | +0.018 +0.007 | +0.029 +0.018 | -0.006 -0.017 | 0 -0.018 | |||

| 18.01 ~ 30.00 | +0.021 +0.008 | +0.035 +0.022 | -0.007 -0.020 | 0 -0.021 | |||

Hard Chrome Plating and buff finished products are not available in Precision Grade Tolerance.

EN 1.4037 Equiv. has an identifcation groove at any position on D part.

Polished, centering hole is sometimes not available for EN 1.4301 Equiv.

When the P dimension is small, a centering hole will cause the sphere section to become small.

The spherical head may be polished.

■Press Fit

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | C | (W) | |||||

| Type | Shape | D Tolerance | P Tolerance | D | ||||||

| KFQ GKFQ* SKFQ HKFQ* CKFQ | (Buff Finished) MKFQ* MGKFQ* Applicable when D≥5. | A (Round) D (Diamond) | M P G H *A *B | S M P G H *A *B | 1 | 1.00~2.50 | 2•3 | 2.0~5.0 | 0.1 | - |

| 2 | 2.00~4.00 | 2~6 | 2.0~10.0 | 0.5 | 1.2 | |||||

| 3 | 3.00~6.00 | 3~6 | 2.0~10.0 | 1.5 | ||||||

| 4 | 4.00~7.00 | 4~8 | 2.0~10.0 | 1 | 1.8 | |||||

| 5 | 5.00~8.00 | 5~10 | 2.0~10.0 | 2.2 | ||||||

| 6 | 6.00~10.00 | 6~12 | 2.0~12.0 | 3.0 | ||||||

| 8 | 8.00~13.00 | 8~16 | 2.0~15.0 | 1.5 | 3.5 | |||||

| 10 | 10.00~15.00 | 10~20 | 3.0~20.0 | 2 | 4.0 | |||||

| 12 | 12.00~16.00 | 12~24 | 3.0~20.0 | 5.0 | ||||||

| 13 | 13.00~18.00 | 13~26 | 5.0~20.0 | 5.5 | ||||||

| 16 | 16.00~25.00 | 16~32 | 5.0~20.0 | 3 | 7.0 | |||||

| 20 | 20.00~30.00 | 20~40 | 5.0~20.0 | 9.0 | ||||||

■Tapped

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | (W) | M (Coarse) | * Tightening Torque N•cm | ℓ | |||||

| Type | Shape | D Tolerance | P Tolerance | D | ||||||||

| KFQT GKFQT SKFQT CKFQT | (Buff Finished) MGKFQT MCKFQT | A (Round) D (Diamond) | M P G H | S M P G H | 5 | 5.00~8.00 | 5(9)~10 | 2.0~10.0 | 2.2 | M2 | - | 3 |

| 6 | 6.00~10.00 | 6(9)~12 | 2.0~12.0 | 3 | M3 | 98 | 5 | |||||

| 6T | M2.6 | - | 4 | |||||||||

| 8 | 8.00~13.00 | 8(12)~16 | 2.0~15.0 | 3.5 | M5 | 461 | 8 | |||||

| 8T | 6(12)~16 | M4 | 225 | 6 | ||||||||

| 10 | 10.00~15.00 | 10(12)~20 | 3.0~20.0 | 4 | M5 | 461 | 8 | |||||

| 10T | 6(12)~16 | M4 | 225 | 6 | ||||||||

| 12 | 12.00~16.00 | 12~24 | 3.0~20.0 | 5 | M5 | 461 | 8 | |||||

| 12T | 8(12)~18 | M4 | 225 | 6 | ||||||||

| 13 | 13.00~18.00 | 13(14)~26 | 5.0~20.0 | 5.5 | M8 | 1911 | 10 | |||||

| 13T | 8(14)~20 | M6 | 784 | 9 | ||||||||

| 16 | 16.00~25.00 | 16~32 | 5.0~20.0 | 7 | M8 | 1911 | 12 | |||||

| 16T | 10(14)~24 | M6 | 784 | 9 | ||||||||

| 20 | 20.00~30.00 | 20~40 | 5.0~20.0 | 9 | M8 | 1911 | 12 | |||||

| 20T | 12(18)~30 | M6 | 784 | 9 | ||||||||

L dimension in ( ) is applicable to Diamond Shape. Note the strength of under-head part. >> P.1566 Please confirm pilot hole depth on >> P.1566. Holes may go through.

* The tightening torque (ref. value) for hardened products is strength class 8.8. (See technical data on >> P. 2297.) Not applicable when using locking materials or lock washers.

■Threaded

| Part Number | P 0.01mm Increment | L 1mm Increment | B 0.1mm Increment | (W) | M | * Tightening Torque N•cm | |||||

| Type | Shape | D Tolerance | P Tolerance | D | |||||||

| KFQN GKFQN* SKFQN CKFQN | (Buff Finished) MGKFQN* Applicable when D≥5. | A (Round) D (Diamond) | M P G H *A *B | S M P G H *A *B | 3 | 3.50~6.00 | 2~6 | 2.0~10.0 | 1.5 | M 3 | 98 |

| 4 | 4.50~7.00 | 2~8 | 2.0~10.0 | 1.8 | M 4 | 225 | |||||

| 5 | 5.50~8.00 | 3~10 | 2.0~10.0 | 2.2 | M 5 | 461 | |||||

| 6 | 6.50~10.00 | 3~10 | 2.0~12.0 | 3 | M 6 | 784 | |||||

| 8 | 9.00~13.00 | 5~10 | 2.0~15.0 | 3.5 | M 8 | 1911 | |||||

| 10 | 11.00~15.00 | 5~15 | 3.0~20.0 | 4 | M10 | 3783 | |||||

| 12 | 13.00~18.00 | 8~15 | 3.0~20.0 | 5 | M12 | 6605 | |||||

| 16 | 17.00~25.00 | 8~20 | 5.0~20.0 | 7 | M16 | 16366 | |||||

| 20 | 22.00~30.00 | 10~20 | 5.0~20.0 | 9 | M20 | 32928 | |||||

* The tightening torque (ref. value) for hardened products is strength class 8.8. (See technical data on >>P. 2297.) Not applicable when using locking materials or lock washers.

Alterations

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| MCKFQTDGG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDGH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDGM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDGP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDGS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDHG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDHH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDHM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDHP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDHS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDMG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDMH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDMM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDMP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDMS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDPG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDPH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDPM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDPP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MCKFQTDPS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAGG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAGH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAGM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAGP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAGS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAHG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAHH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAHM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAHP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAHS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAMG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAMH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAMM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAMP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAMS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAPG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAPH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAPM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAPP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTAPS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDGG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDGH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDGM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDGP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDGS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDHG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDHH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDHM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDHP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDHS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDMG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDMH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDMM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDMP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDMS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDPG8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDPH8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDPM8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDPP8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| MGKFQTDPS8T-P[8-13/0.01]-L[6-16/1]-B[2-15/0.1] |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Inlet Side Tip Shape | Mounting Side Shape | Surface Treatment | Heat Treatment | Material | Steel Type | Stainless Steel Type | Locating Section Outer Dia. P (Ø) | Positioning Side O.D. Tolerance | Mounting Side Dia. D (Ø) | Mounting Side Outer Dia. Tolerance | Screw Dia. M (mm) | Mounting Section Length L (mm) | Positioning Part Length B (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | g6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | h7 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | m6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | p6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | 0/-0.01 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | g6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | h7 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | m6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | p6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | 0/-0.01 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | g6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | h7 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | m6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | p6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | 0/-0.01 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | g6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | h7 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | m6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | p6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Buffing | Directly Quenched | Stainless Steel | - | EN 1.4037 Equiv. | 8 ~ 13 | 0/-0.01 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Round | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | g6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | h7 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | m6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | g6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | h7 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | m6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | p6 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 | ||

- | 1 | 6 Days | 10 | Diamond | Female Thread | Hard Chrome Plating + Buff finished | Directly Quenched | Steel | Equivalent to SKS3 | - | 8 ~ 13 | 0/-0.01 | 8T | p6 | 4 | 6 ~ 16 | 2 ~ 15 |

Loading...

Basic information

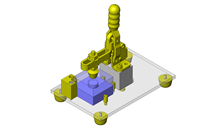

| Basic Shape | Large Head | Inlet Side Tip Type | Spherical Surface | Inlet Style | No |

|---|

Configure

Basic Attributes

-

Inlet Side Tip Shape

-

Round

Round -

Diamond

Diamond

-

-

Mounting Side Shape

-

Straight(Press Fit)

Straight(Press Fit) -

Female Thread

Female Thread -

Male thread

Male thread

-

-

Surface Treatment

- Not Provided

- Hard Chrome Plating

- Buffing

- Hard Chrome Plating + Buff finished

-

Heat Treatment

- No

- Directly Quenched

-

Material

- Steel

- Stainless Steel

-

Steel Type

- Equivalent to SKS3

-

Stainless Steel Type

-

Locating Section Outer Dia. P(Ø)

-

Positioning Side O.D. Tolerance

-

Mounting Side Outer Dia. Tolerance

-

Screw Dia. M(mm)

-

Mounting Section Length L(mm)

-

Positioning Part Length B(mm)

-

Type

- CKFQAAA

- CKFQAAB

- CKFQAAG

- CKFQAAH

- CKFQAAM

- CKFQAAP

- CKFQAAS

- CKFQABA

- CKFQABB

- CKFQABG

- CKFQABH

- CKFQABM

- CKFQABP

- CKFQABS

- CKFQAGA

- CKFQAGB

- CKFQAGG

- CKFQAGH

- CKFQAGM

- CKFQAGP

- CKFQAGS

- CKFQAHA

- CKFQAHB

- CKFQAHG

- CKFQAHH

- CKFQAHM

- CKFQAHP

- CKFQAHS

- CKFQAMA

- CKFQAMB

- CKFQAMG

- CKFQAMH

- CKFQAMM

- CKFQAMP

- CKFQAMS

- CKFQAPA

- CKFQAPB

- CKFQAPG

- CKFQAPH

- CKFQAPM

- CKFQAPP

- CKFQAPS

- CKFQDAA

- CKFQDAB

- CKFQDAG

- CKFQDAH

- CKFQDAM

- CKFQDAP

- CKFQDAS

- CKFQDBA

- CKFQDBB

- CKFQDBG

- CKFQDBH

- CKFQDBM

- CKFQDBP

- CKFQDBS

- CKFQDGA

- CKFQDGB

- CKFQDGG

- CKFQDGH

- CKFQDGM

- CKFQDGP

- CKFQDGS

- CKFQDHA

- CKFQDHB

- CKFQDHG

- CKFQDHH

- CKFQDHM

- CKFQDHP

- CKFQDHS

- CKFQDMA

- CKFQDMB

- CKFQDMG

- CKFQDMH

- CKFQDMM

- CKFQDMP

- CKFQDMS

- CKFQDPA

- CKFQDPB

- CKFQDPG

- CKFQDPH

- CKFQDPM

- CKFQDPP

- CKFQDPS

- CKFQNAAA

- CKFQNAAB

- CKFQNAAG

- CKFQNAAH

- CKFQNAAM

- CKFQNAAP

- CKFQNAAS

- CKFQNABA

- CKFQNABB

- CKFQNABG

- CKFQNABH

- CKFQNABM

- CKFQNABP

- CKFQNABS

- CKFQNAGA

- CKFQNAGB

- CKFQNAGG

- CKFQNAGH

- CKFQNAGM

- CKFQNAGP

- CKFQNAGS

- CKFQNAHA

- CKFQNAHB

- CKFQNAHG

- CKFQNAHH

- CKFQNAHM

- CKFQNAHP

- CKFQNAHS

- CKFQNAMA

- CKFQNAMB

- CKFQNAMG

- CKFQNAMH

- CKFQNAMM

- CKFQNAMP

- CKFQNAMS

- CKFQNAPA

- CKFQNAPB

- CKFQNAPG

- CKFQNAPH

- CKFQNAPM

- CKFQNAPP

- CKFQNAPS

- CKFQNDAA

- CKFQNDAB

- CKFQNDAG

- CKFQNDAH

- CKFQNDAM

- CKFQNDAP

- CKFQNDAS

- CKFQNDBA

- CKFQNDBB

- CKFQNDBG

- CKFQNDBH

- CKFQNDBM

- CKFQNDBP

- CKFQNDBS

- CKFQNDGA

- CKFQNDGB

- CKFQNDGG

- CKFQNDGH

- CKFQNDGM

- CKFQNDGP

- CKFQNDGS

- CKFQNDHA

- CKFQNDHB

- CKFQNDHG

- CKFQNDHH

- CKFQNDHM

- CKFQNDHP

- CKFQNDHS

- CKFQNDMA

- CKFQNDMB

- CKFQNDMG

- CKFQNDMH

- CKFQNDMM

- CKFQNDMP

- CKFQNDMS

- CKFQNDPA

- CKFQNDPB

- CKFQNDPG

- CKFQNDPH

- CKFQNDPM

- CKFQNDPP

- CKFQNDPS

- CKFQTAGG

- CKFQTAGH

- CKFQTAGM

- CKFQTAGP

- CKFQTAGS

- CKFQTAHG

- CKFQTAHH

- CKFQTAHM

- CKFQTAHP

- CKFQTAHS

- CKFQTAMG

- CKFQTAMH

- CKFQTAMM

- CKFQTAMP

- CKFQTAMS

- CKFQTAPG

- CKFQTAPH

- CKFQTAPM

- CKFQTAPP

- CKFQTAPS

- GKFQAGG

- GKFQAGH

- GKFQAGM

- GKFQAGP

- GKFQAGS

- GKFQAHG

- GKFQAHH

- GKFQAHM

- GKFQAHP

- GKFQAHS

- GKFQAMG

- GKFQAMH

- GKFQAMM

- GKFQAMP

- GKFQAMS

- GKFQAPG

- GKFQAPH

- GKFQAPM

- GKFQAPP

- GKFQAPS

- GKFQDGG

- GKFQDGH

- GKFQDGM

- GKFQDGP

- GKFQDGS

- GKFQDHG

- GKFQDHH

- GKFQDHM

- GKFQDHP

- GKFQDHS

- GKFQDMG

- GKFQDMH

- GKFQDMM

- GKFQDMP

- GKFQDMS

- GKFQDPG

- GKFQDPH

- GKFQDPM

- GKFQDPP

- GKFQDPS

- GKFQNABS

- GKFQNAGG

- GKFQNAGH

- GKFQNAGM

- GKFQNAGP

- GKFQNAGS

- GKFQNAHG

- GKFQNAHH

- GKFQNAHM

- GKFQNAHP

- GKFQNAHS

- GKFQNAMG

- GKFQNAMH

- GKFQNAMM

- GKFQNAMP

- GKFQNAMS

- GKFQNAPG

- GKFQNAPH

- GKFQNAPM

- GKFQNAPP

- GKFQNAPS

- GKFQTAGG

- GKFQTAGH

- GKFQTAGM

- GKFQTAGP

- GKFQTAGS

- GKFQTAHG

- GKFQTAHH

- GKFQTAHM

- GKFQTAHP

- GKFQTAHS

- GKFQTAMG

- GKFQTAMH

- GKFQTAMM

- GKFQTAMP

- GKFQTAMS

- GKFQTAPG

- GKFQTAPH

- GKFQTAPM

- GKFQTAPP

- GKFQTAPS

- GKFQTDGG

- GKFQTDGH

- GKFQTDGM

- GKFQTDGP

- GKFQTDGS

- GKFQTDHG

- GKFQTDHH

- GKFQTDHM

- GKFQTDHP

- GKFQTDHS

- GKFQTDMG

- GKFQTDMH

- GKFQTDMM

- GKFQTDMP

- GKFQTDMS

- GKFQTDPG

- GKFQTDPH

- GKFQTDPM

- GKFQTDPP

- GKFQTDPS

- HKFQAGG

- HKFQAGH

- HKFQAGM

- HKFQAGP

- HKFQAGS

- HKFQAHG

- HKFQAHH

- HKFQAHM

- HKFQAHP

- HKFQAHS

- HKFQAMG

- HKFQAMH

- HKFQAMM

- HKFQAMP

- HKFQAMS

- HKFQAPG

- HKFQAPH

- HKFQAPM

- HKFQAPP

- HKFQAPS

- HKFQDGG

- HKFQDGH

- HKFQDGM

- HKFQDGP

- HKFQDGS

- HKFQDHG

- HKFQDHH

- HKFQDHM

- HKFQDHP

- HKFQDHS

- HKFQDMG

- HKFQDMH

- HKFQDMM

- HKFQDMP

- HKFQDMS

- HKFQDPG

- HKFQDPH

- HKFQDPM

- HKFQDPP

- HKFQDPS

- KFQAAA

- KFQAAB

- KFQAAG

- KFQAAH

- KFQAAM

- KFQAAP

- KFQAAS

- KFQABA

- KFQABB

- KFQABG

- KFQABH

- KFQABM

- KFQABP

- KFQABS

- KFQAGA

- KFQAGB

- KFQAGG

- KFQAGH

- KFQAGM

- KFQAGP

- KFQAGS

- KFQAHA

- KFQAHB

- KFQAHG

- KFQAHH

- KFQAHM

- KFQAHP

- KFQAHS

- KFQAMA

- KFQAMB

- KFQAMG

- KFQAMH

- KFQAMM

- KFQAMP

- KFQAMS

- KFQAPA

- KFQAPB

- KFQAPG

- KFQAPH

- KFQAPM

- KFQAPP

- KFQAPS

- KFQDAA

- KFQDAB

- KFQDAG

- KFQDAH

- KFQDAM

- KFQDAP

- KFQDAS

- KFQDBA

- KFQDBB

- KFQDBG

- KFQDBH

- KFQDBM

- KFQDBP

- KFQDBS

- KFQDGA

- KFQDGB

- KFQDGG

- KFQDGH

- KFQDGM

- KFQDGP

- KFQDGS

- KFQDHA

- KFQDHB

- KFQDHG

- KFQDHH

- KFQDHM

- KFQDHP

- KFQDHS

- KFQDMA

- KFQDMB

- KFQDMG

- KFQDMH

- KFQDMM

- KFQDMP

- KFQDMS

- KFQDPA

- KFQDPB

- KFQDPG

- KFQDPH

- KFQDPM

- KFQDPP

- KFQDPS

- KFQNAAA

- KFQNAAB

- KFQNAAG

- KFQNAAH

- KFQNAAM

- KFQNAAP

- KFQNAAS

- KFQNABA

- KFQNABB

- KFQNABG

- KFQNABH

- KFQNABM

- KFQNABP

- KFQNABS

- KFQNAGA

- KFQNAGB

- KFQNAGG

- KFQNAGH

- KFQNAGM

- KFQNAGP

- KFQNAGS

- KFQNAHA

- KFQNAHB

- KFQNAHG

- KFQNAHH

- KFQNAHM

- KFQNAHP

- KFQNAHS

- KFQNAMA

- KFQNAMB

- KFQNAMG

- KFQNAMH

- KFQNAMM

- KFQNAMP

- KFQNAMS

- KFQNAPA

- KFQNAPB

- KFQNAPG

- KFQNAPH

- KFQNAPM

- KFQNAPP

- KFQNAPS

- KFQNDAA

- KFQNDAB

- KFQNDAG

- KFQNDAH

- KFQNDAM

- KFQNDAP

- KFQNDAS

- KFQNDBA

- KFQNDBB

- KFQNDBG

- KFQNDBH

- KFQNDBM

- KFQNDBP

- KFQNDBS

- KFQNDGA

- KFQNDGB

- KFQNDGG

- KFQNDGH

- KFQNDGM

- KFQNDGP

- KFQNDGS

- KFQNDHA

- KFQNDHB

- KFQNDHG

- KFQNDHH

- KFQNDHM

- KFQNDHP

- KFQNDHS

- KFQNDMA

- KFQNDMB

- KFQNDMG

- KFQNDMH

- KFQNDMM

- KFQNDMP

- KFQNDMS

- KFQNDPA

- KFQNDPB

- KFQNDPG

- KFQNDPH

- KFQNDPM

- KFQNDPP

- KFQNDPS

- KFQTAGG

- KFQTAGH

- KFQTAGM

- KFQTAGP

- KFQTAGS

- KFQTAHG

- KFQTAHH

- KFQTAHM

- KFQTAHP

- KFQTAHS

- KFQTAMG

- KFQTAMH

- KFQTAMM

- KFQTAMP

- KFQTAMS

- KFQTAPG

- KFQTAPH

- KFQTAPM

- KFQTAPP

- KFQTAPS

- KFQTDGG

- KFQTDGH

- KFQTDGM

- KFQTDGP

- KFQTDGS

- KFQTDHG

- KFQTDHH

- KFQTDHM

- KFQTDHP

- KFQTDHS

- KFQTDMG

- KFQTDMH

- KFQTDMM

- KFQTDMP

- KFQTDMS

- KFQTDPG

- KFQTDPH

- KFQTDPM

- KFQTDPP

- KFQTDPS

- MCKFQAGG

- MCKFQAGH

- MCKFQAGM

- MCKFQAGP

- MCKFQAGS

- MCKFQAHG

- MCKFQAHH

- MCKFQAHM

- MCKFQAHP

- MCKFQAHS

- MCKFQAMG

- MCKFQAMH

- MCKFQAMM

- MCKFQAMP

- MCKFQAMS

- MCKFQAPG

- MCKFQAPH

- MCKFQAPM

- MCKFQAPP

- MCKFQAPS

- MCKFQDGG

- MCKFQDGH

- MCKFQDGM

- MCKFQDGP

- MCKFQDGS

- MCKFQDHG

- MCKFQDHH

- MCKFQDHM

- MCKFQDHP

- MCKFQDHS

- MCKFQDMG

- MCKFQDMH

- MCKFQDMM

- MCKFQDMP

- MCKFQDMS

- MCKFQDPG

- MCKFQDPH

- MCKFQDPM

- MCKFQDPP

- MCKFQDPS

- MCKFQNAGG

- MCKFQNAGH

- MCKFQNAGM

- MCKFQNAGP

- MCKFQNAGS

- MCKFQNAHG

- MCKFQNAHH

- MCKFQNAHM

- MCKFQNAHP

- MCKFQNAHS

- MCKFQNAMG

- MCKFQNAMH

- MCKFQNAMM

- MCKFQNAMP

- MCKFQNAMS

- MCKFQNAPG

- MCKFQNAPH

- MCKFQNAPM

- MCKFQNAPP

- MCKFQNAPS

- MCKFQNDGG

- MCKFQNDGH

- MCKFQNDGM

- MCKFQNDGP

- MCKFQNDGS

- MCKFQNDHG

- MCKFQNDHH

- MCKFQNDHM

- MCKFQNDHP

- MCKFQNDHS

- MCKFQNDMG

- MCKFQNDMH

- MCKFQNDMM

- MCKFQNDMP

- MCKFQNDMS

- MCKFQNDPG

- MCKFQNDPH

- MCKFQNDPM

- MCKFQNDPP

- MCKFQNDPS

- MCKFQTAGG

- MCKFQTAGH

- MCKFQTAGM

- MCKFQTAGP

- MCKFQTAGS

- MCKFQTAHG

- MCKFQTAHH

- MCKFQTAHM

- MCKFQTAHP

- MCKFQTAHS

- MCKFQTAMG

- MCKFQTAMH

- MCKFQTAMM

- MCKFQTAMP

- MCKFQTAMS

- MCKFQTAPG

- MCKFQTAPH

- MCKFQTAPM

- MCKFQTAPP

- MCKFQTAPS

- MCKFQTDGG

- MCKFQTDGH

- MCKFQTDGM

- MCKFQTDGP

- MCKFQTDGS

- MCKFQTDHG

- MCKFQTDHH

- MCKFQTDHM

- MCKFQTDHP

- MCKFQTDHS

- MCKFQTDMG

- MCKFQTDMH

- MCKFQTDMM

- MCKFQTDMP

- MCKFQTDMS

- MCKFQTDPG

- MCKFQTDPH

- MCKFQTDPM

- MCKFQTDPP

- MCKFQTDPS

- MGKFQAGG

- MGKFQAGH

- MGKFQAGM

- MGKFQAGP

- MGKFQAGS

- MGKFQAHG

- MGKFQAHH

- MGKFQAHM

- MGKFQAHP

- MGKFQAHS

- MGKFQAMG

- MGKFQAMH

- MGKFQAMM

- MGKFQAMP

- MGKFQAMS

- MGKFQAPG

- MGKFQAPH

- MGKFQAPM

- MGKFQAPP

- MGKFQAPS

- MGKFQDGG

- MGKFQDGH

- MGKFQDGM

- MGKFQDGP

- MGKFQDGS

- MGKFQDHG

- MGKFQDHH

- MGKFQDHM

- MGKFQDHP

- MGKFQDHS

- MGKFQDMG

- MGKFQDMH

- MGKFQDMM

- MGKFQDMP

- MGKFQDMS

- MGKFQDPG

- MGKFQDPH

- MGKFQDPM

- MGKFQDPP

- MGKFQDPS

- MGKFQNAGG

- MGKFQNAGH

- MGKFQNAGM

- MGKFQNAGP

- MGKFQNAGS

- MGKFQNAHG

- MGKFQNAHH

- MGKFQNAHM

- MGKFQNAHP

- MGKFQNAHS

- MGKFQNAMG

- MGKFQNAMH

- MGKFQNAMM

- MGKFQNAMP

- MGKFQNAMS

- MGKFQNAPG

- MGKFQNAPH

- MGKFQNAPM

- MGKFQNAPP

- MGKFQNAPS

- MGKFQNDGG

- MGKFQNDGH

- MGKFQNDGM

- MGKFQNDGP

- MGKFQNDGS

- MGKFQNDHG

- MGKFQNDHH

- MGKFQNDHM

- MGKFQNDHP

- MGKFQNDHS

- MGKFQNDMG

- MGKFQNDMH

- MGKFQNDMM

- MGKFQNDMP

- MGKFQNDMS

- MGKFQNDPG

- MGKFQNDPH

- MGKFQNDPM

- MGKFQNDPP

- MGKFQNDPS

- MGKFQTAGG

- MGKFQTAGH

- MGKFQTAGM

- MGKFQTAGP

- MGKFQTAGS

- MGKFQTAHG

- MGKFQTAHH

- MGKFQTAHM

- MGKFQTAHP

- MGKFQTAHS

- MGKFQTAMG

- MGKFQTAMH

- MGKFQTAMM

- MGKFQTAMP

- MGKFQTAMS

- MGKFQTAPG

- MGKFQTAPH

- MGKFQTAPM

- MGKFQTAPP

- MGKFQTAPS

- MGKFQTDGG

- MGKFQTDGH

- MGKFQTDGM

- MGKFQTDGP

- MGKFQTDGS

- MGKFQTDHG

- MGKFQTDHH

- MGKFQTDHM

- MGKFQTDHP

- MGKFQTDHS

- MGKFQTDMG

- MGKFQTDMH

- MGKFQTDMM

- MGKFQTDMP

- MGKFQTDMS

- MGKFQTDPG

- MGKFQTDPH

- MGKFQTDPM

- MGKFQTDPP

- MGKFQTDPS

- MKFQAGG

- MKFQAGH

- MKFQAGM

- MKFQAGP

- MKFQAGS

- MKFQAHG

- MKFQAHH

- MKFQAHM

- MKFQAHP

- MKFQAHS

- MKFQAMG

- MKFQAMH

- MKFQAMM

- MKFQAMP

- MKFQAMS

- MKFQAPG

- MKFQAPH

- MKFQAPM

- MKFQAPP

- MKFQAPS

- MKFQDGG

- MKFQDGH

- MKFQDGM

- MKFQDGP

- MKFQDGS

- MKFQDHG

- MKFQDHH

- MKFQDHM

- MKFQDHP

- MKFQDHS

- MKFQDMG

- MKFQDMH

- MKFQDMM

- MKFQDMP

- MKFQDMS

- MKFQDPG

- MKFQDPH

- MKFQDPM

- MKFQDPP

- MKFQDPS

- MKFQNAGG

- MKFQNAGH

- MKFQNAGM

- MKFQNAGP

- MKFQNAGS

- MKFQNAHG

- MKFQNAHH

- MKFQNAHM

- MKFQNAHP

- MKFQNAHS

- MKFQNAMG

- MKFQNAMH

- MKFQNAMM

- MKFQNAMP

- MKFQNAMS

- MKFQNAPG

- MKFQNAPH

- MKFQNAPM

- MKFQNAPP

- MKFQNAPS

- MKFQNDGG

- MKFQNDGH

- MKFQNDGM

- MKFQNDGP

- MKFQNDGS

- MKFQNDHG

- MKFQNDHH

- MKFQNDHM

- MKFQNDHP

- MKFQNDHS

- MKFQNDMG

- MKFQNDMH

- MKFQNDMM

- MKFQNDMP

- MKFQNDMS

- MKFQNDPG

- MKFQNDPH

- MKFQNDPM

- MKFQNDPP

- MKFQNDPS

- MKFQTAGG

- MKFQTAGH

- MKFQTAGM

- MKFQTAGP

- MKFQTAGS

- MKFQTAHG

- MKFQTAHH

- MKFQTAHM

- MKFQTAHP

- MKFQTAHS

- MKFQTAMG

- MKFQTAMH

- MKFQTAMM

- MKFQTAMP

- MKFQTAMS

- MKFQTAPG

- MKFQTAPH

- MKFQTAPM

- MKFQTAPP

- MKFQTAPS

- MKFQTDGG

- MKFQTDGH

- MKFQTDGM

- MKFQTDGP

- MKFQTDGS

- MKFQTDHG

- MKFQTDHH

- MKFQTDHM

- MKFQTDHP

- MKFQTDHS

- MKFQTDMG

- MKFQTDMH

- MKFQTDMM

- MKFQTDMP

- MKFQTDMS

- MKFQTDPG

- MKFQTDPH

- MKFQTDPM

- MKFQTDPP

- MKFQTDPS

- SKFQAAA

- SKFQAAB

- SKFQAAG

- SKFQAAH

- SKFQAAM

- SKFQAAP

- SKFQAAS

- SKFQABA

- SKFQABB

- SKFQABG

- SKFQABH

- SKFQABM

- SKFQABP

- SKFQABS

- SKFQAGA

- SKFQAGB

- SKFQAGG

- SKFQAGH

- SKFQAGM

- SKFQAGP

- SKFQAGS

- SKFQAHA

- SKFQAHB

- SKFQAHG

- SKFQAHH

- SKFQAHM

- SKFQAHP

- SKFQAHS

- SKFQAMA

- SKFQAMB

- SKFQAMG

- SKFQAMH

- SKFQAMM

- SKFQAMP

- SKFQAMS

- SKFQAPA

- SKFQAPB

- SKFQAPG

- SKFQAPH

- SKFQAPM

- SKFQAPP

- SKFQAPS

- SKFQDAA

- SKFQDAB

- SKFQDAG

- SKFQDAH

- SKFQDAM

- SKFQDAP

- SKFQDAS

- SKFQDBA

- SKFQDBB

- SKFQDBG

- SKFQDBH

- SKFQDBM

- SKFQDBP

- SKFQDBS

- SKFQDGA

- SKFQDGB

- SKFQDGG

- SKFQDGH

- SKFQDGM

- SKFQDGP

- SKFQDGS

- SKFQDHA

- SKFQDHB

- SKFQDHG

- SKFQDHH

- SKFQDHM

- SKFQDHP

- SKFQDHS

- SKFQDMA

- SKFQDMB

- SKFQDMG

- SKFQDMH

- SKFQDMM

- SKFQDMP

- SKFQDMS

- SKFQDPA

- SKFQDPB

- SKFQDPG

- SKFQDPH

- SKFQDPM

- SKFQDPP

- SKFQDPS

- SKFQNAAA

- SKFQNAAB

- SKFQNAAG

- SKFQNAAH

- SKFQNAAM

- SKFQNAAP

- SKFQNAAS

- SKFQNABA

- SKFQNABB

- SKFQNABG

- SKFQNABH

- SKFQNABM

- SKFQNABP

- SKFQNABS

- SKFQNAGA

- SKFQNAGB

- SKFQNAGG

- SKFQNAGH

- SKFQNAGM

- SKFQNAGP

- SKFQNAGS

- SKFQNAHA

- SKFQNAHB

- SKFQNAHG

- SKFQNAHH

- SKFQNAHM

- SKFQNAHP

- SKFQNAHS

- SKFQNAMA

- SKFQNAMB

- SKFQNAMG

- SKFQNAMH

- SKFQNAMM

- SKFQNAMP

- SKFQNAMS

- SKFQNAPA

- SKFQNAPB

- SKFQNAPG

- SKFQNAPH

- SKFQNAPM

- SKFQNAPP

- SKFQNAPS

- SKFQNDAA

- SKFQNDAB

- SKFQNDAG

- SKFQNDAH

- SKFQNDAM

- SKFQNDAP

- SKFQNDAS

- SKFQNDBA

- SKFQNDBB

- SKFQNDBG

- SKFQNDBH

- SKFQNDBM

- SKFQNDBP

- SKFQNDBS

- SKFQNDGA

- SKFQNDGB

- SKFQNDGG

- SKFQNDGH

- SKFQNDGM

- SKFQNDGP

- SKFQNDGS

- SKFQNDHA

- SKFQNDHB

- SKFQNDHG

- SKFQNDHH

- SKFQNDHM

- SKFQNDHP

- SKFQNDHS

- SKFQNDMA

- SKFQNDMB

- SKFQNDMG

- SKFQNDMH

- SKFQNDMM

- SKFQNDMP

- SKFQNDMS

- SKFQNDPA

- SKFQNDPB

- SKFQNDPG

- SKFQNDPH

- SKFQNDPM

- SKFQNDPP

- SKFQNDPS

- SKFQTAGG

- SKFQTAGH

- SKFQTAGM

- SKFQTAGP

- SKFQTAGS

- SKFQTAHG

- SKFQTAHH

- SKFQTAHM

- SKFQTAHP

- SKFQTAHS

- SKFQTAMG

- SKFQTAMH

- SKFQTAMM

- SKFQTAMP

- SKFQTAMS

- SKFQTAPG

- SKFQTAPH

- SKFQTAPM

- SKFQTAPP

- SKFQTAPS

-

Mounting Side Dia. D(Ø)

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 5 Days or Less

- 6 Days or Less

- 7 Days or Less

- 8 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)