- inCAD Library Home

- > No.000095 Soldering hand with air purge

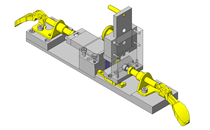

No.000095 Soldering hand with air purge

Simple nozzle and distance adjustments.

Related Category

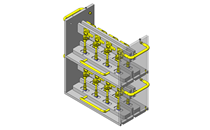

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

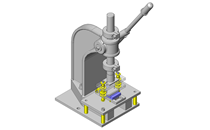

- Air purge nozzle removes post-solder oxidation material from soldering iron tip.

Points for use

- The air purge should be done away from the work piece. A suction component should also be used to prevent secondary contamination.

- Adjust the nozzle position for most effective air purging of oxidation.

Target workpiece

- Electronic PC board

Dims.: W50 x H50 x t1

Weight: 0.1kg

Design Specifications

Operating Conditions or Design Requirements

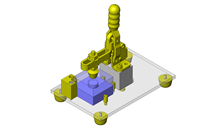

- External dims.: W65 x D125 x H160

Selection Criteria for Main Components

- Air blow nozzle

- Select a nozzle with sufficient air flow to pin point blow off oxidized material on soldering iron tip.

Design Evaluation

Verification of main components

- Verify required air flow volume

- Various conditions

- Nozzle I.D.: A = 1mm

- Operating pressure: P = 0.4Mpa

- Absolute pressure: P₁ = 0.4 + 0.101Mpa

- Flow factor: C = 100% = 1

- Temp.: 20°C

- Absolute temp.: T₁ = t + 273K

- Specific gravity of air: 1.2kg/m³ (20°C time)

- Assuming that the air flow rate through the nozzle is Q

- Q = 2419.9 / 1.2 x (A x C x P₁) /√T₁

= 2419.9 / 1.2 x (π x 12 / 4 x 1 x 0.4 + 0.101) / √(20 + 273)

= 46.4L/min, - Although the frequency of air purging needs to be separately verified, it is determined that required air flow is satisfactory.

Other Design Consideration

- The nozzle mount must be rigid, while still providing the ability for the necessary rotary and angle adjustments.

- The flow volume, timing and frequency must be controlled to make sure the iron temperature is not decreased during use.

Explore Similar Application Examples

Page

-

/

-