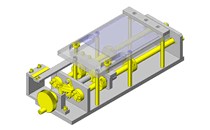

Cam Followers

| Product name | Cam Followers/Hex Hole/Crown Type/No Seal |

| Part number | CFUA6-16 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

In order to configure a knuckle joint to support rotating object.

Back to page top

Available sizes

■Cam Followers

| Applications | Body | Nut |

| Material | Seal | Material | Surface Treatment |

| Not provided | Provided |

| General | EN 1.3505 Equiv. | ○ | ○ | EN 1.1191 Equiv. | Black Oxide Coating |

| EN 1.4125 Equiv. | ○ | ○ | EN 1.4301 Equiv. | - |

| Low Dust Generation | - | ○ |

■Sizes and Dimensions

| Stud Dia. | Thread diameter x pitch | Outer Ring Diameter | Outer Ring Width | Overall Length |

| Ø3 | M3 x 0.5 | Ø10 | 7 | 17 |

| Ø4 | M4 x 0.7 | Ø12 | 8 | 20 |

| Ø5 | M5 x 0.8 | Ø13 | 9 | 23 |

| Ø6 | M6 x 1.0 | Ø16 | 11 | 28 |

| Ø8 | M8 x 1.25 | Ø19 | 11 | 32 |

| Ø10 | M10 x 1.25 | Ø22 | 12 | 36 |

| Ø26 |

| Ø12 | M12 x 1.5 | Ø30 | 14 | 40 |

| Ø32 |

Back to page top

Accuracy Info

■Accuracy of Cam Followers

Stud Diameter Tolerance: h7.

Outer Ring Width Tolerance: 0/-0.12.

Outer Ring Diameter Tolerance:

| Outer Ring DIA. | Tolerance |

| Ø10 | 0/-0.008 |

| Ø12 |

| Ø13 |

| Ø16 |

| Ø19 | 0/-0.009 |

| Ø22 |

| Ø26 |

| Ø30 |

| Ø32 | 0/-0.011 |

■Rated load and rotation speed of cam follower

Stud Dia.

- Outer Ring Dia. | Basic

Dynamic Load Rating

C (kN) | Basic

Static Load Rating

Cor (kN) | Max.

Allowable Load

(kN) | Track

Load Capacity

(kN) | Max. Rotational Speed (rpm) |

| With Seal | No Seal |

| Ø3-Ø10 | 1.47 | 1.18 | 0.36 | 1.37 | 32900 | 47000 |

| Ø4-Ø12 | 2.06 | 2.05 | 0.78 | 1.76 | 25900 | 37000 |

| Ø5-Ø13 | 3.14 | 2.77 | 1.42 | 2.25 | 20300 | 29000 |

| Ø6-Ø16 | 3.59 | 3.58 | 2.11 | 3.43 | 17500 | 25000 |

| Ø8-Ø19 | 4.17 | 4.65 | 4.73 | 4.02 | 14000 | 20000 |

| Ø10-Ø22 | 5.33 | 6.78 | 5.81 | 4.7 | 11900 | 17000 |

| Ø10-Ø26 | 5.49 |

| Ø12-Ø30 | 7.87 | 9.79 | 9.37 | 7.06 | 9800 | 14000 |

| Ø12-Ø32 | 7.45 |

Back to page top

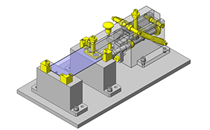

Ball Spline

* Orange colored cells in the table below indicate the part numbers used in this example.

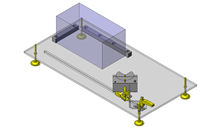

Selection criteria

Selection to realize unit for rotation and linear motion simultaneously in a compact manner.

Back to page top

Available sizes

■Ball Splines - One End Tapped

| Material |

Spline Shaft : EN 1.3505 Equiv.

Nut : EN 1.7242 Equiv.

Hardness 58HRC or more | Spline Shaft : EN 1.4125 Equiv.

Nut : EN 1.4125 Equiv.

Hardness 55HRC or more |

| With Round Flange Nut | ○ | ○ |

| With Compact Flange Nut | ○ | - |

| With Straight Nut | ○ | - |

■Sizes and Dimensions

| Nominal | Spline Shaft Length | Tap Dia. | Shaft O.D. |

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 |

| 6 | 60-400 | ○ | - | - | - | - | - | - | - | 6 |

| 8 | 60-400 | ○ | ○ | - | - | - | - | - | - | 8 |

| 10 | 60-600 | ○ | ○ | ○ | - | - | - | - | - | 10.4 |

| 13 | 60-600 | - | ○ | ○ | ○ | - | - | - | - | 13.4 |

| 16 | 70-600 | - | ○ | ○ | ○ | ○ | - | - | - | 16.6 |

| 20 | 80-700 | - | - | ○ | ○ | ○ | ○ | - | - | 20.6 |

| 25 | 90-900 | - | - | ○ | ○ | ○ | ○ | ○ | - | 25.8 |

| 30 | 100-1150 | - | - | - | ○ | ○ | ○ | ○ | ○ | 30.8 |

Back to page top

Selection steps

■Selection Steps of Ball Spline

- Determining conditions of use.

- (Load, Torque, Feed distance, Life).

↓

- Temporary selection of specification of ball spline.

- (Spline shaft diameter, spline shaft length and overall length are temporary determined in accordance with application condition).

↓

- Basic Safety Check.

-

- ●Allowable Load.

- ●Service Life.

Back to page top

Accuracy Info

■Accuracy of Ball Spline Shaft

(μm)

Name

No. | Spline

Shaft Diameter | Max.

Runout of

Nut O.D. | | Max. Runout of Spline Axis Line |

| Length | -200 | 201-315 | 316-400 | 401-500 | 501-630 | 630-800 | 801-1000 | 1001- |

| 6 | Ø6 | 11 | 46 | 89 | 126 | 163 | - | - | - | - |

| 8 | Ø8 |

| 10 | Ø10.4 | 13 | 36 | 54 | 68 | 82 | 102 | - | - | - |

| 13 | Ø13.4 | 16 | 34 | 45 | 53 | 62 | 75 | - | - | - |

| 16 | Ø16.6 |

| 20 | Ø20.6 | 19 | 32 | 39 | 44 | 50 | 57 | 68 | 83 | 102 |

| 25 | Ø25.8 |

| 30 | Ø30.8 |

Back to page top

Performance info.

■Rated Load of Ball Spline

Name

No. | Basic rated Torque | Basic Load Rating | Allowable Static Moment |

| Dynamic (Nm) | Static (Nm) | Dynamic (kN) | Static (kN) | M 01 (N・m) | M 02 (N・m) |

| 6 | 3.8 | 7 | 1.2 | 2.1 | 5 | 36 |

| 8 | 4.8 | 8.7 | 1.2 | 2.1 | 5 | 36 |

| 10 | 19 | 34 | 3.8 | 6.9 | 26 | 181 |

| 13 | 28 | 52 | 4.6 | 8.3 | 36 | 251 |

| 16 | 51 | 93 | 6.2 | 11.1 | 56 | 386 |

| 20 | 85 | 154 | 8.5 | 15.3 | 83 | 611 |

| 25 | 193 | 348 | 15.4 | 27.7 | 173 | 1248 |

| 30 | 272 | 490 | 18.5 | 33.3 | 212 | 1581 |

Back to page top

Technical Calculations

■Calculation of Service Life of Ball Spline

Use the following formula for calculating the running service life of the ball spline.

- L: Running Life (km).

- ft: Temperature Factor.

- fh: Hardness Factor.

- fp: Ratio of Rated Load.

- fw: Load Factor.

- L0: Rated Life (50km).

- C: Basic Dynamic Load Rating (N).

- F: Applied Radial Load (N).

- Ct: Basic Dynamic Torque (N・m).

- T: Applied Torque (N・m).

Use the following formula for calculating the service life of the ball spline.

- Lh: Run Time (hr).

- L: Running Life (km).

- St: Stroke Length (mm).

- n: Reciprocating Cycles per Minute (cpm).

■Ratio of Rated Load (fp)

| Name No. | Spline Shaft Diameter. | Load Divided | Direct Download |

| 10 | Ø10.4 | 1 | 0.71 |

| 13 | Ø13.4 | 1 | 0.71 |

| 16 | Ø16.6 | 1 | 0.68 |

■Load Factor (fw)

| Usage Condition | Load Factor (fw) |

Minimal vibrations

shocks (slow speed travel 1 to 2 15 m/min or less) | 1-2 |

Some vibrations

shocks(medium speed travel 2 to 3 60 m/min or less) | 2-3 |

Severe vibrations

shocks (high speed travel 3 or more over 60m/min.) | 3- |

Back to page top

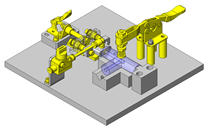

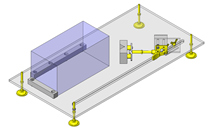

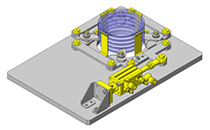

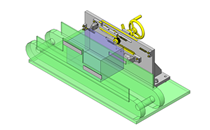

IDEA NOTE A ball spline mechanism that works as a guide

The ball spline not only allows for up and down motion, but also shaft rotary motion for guiding and transferring of workpiece.

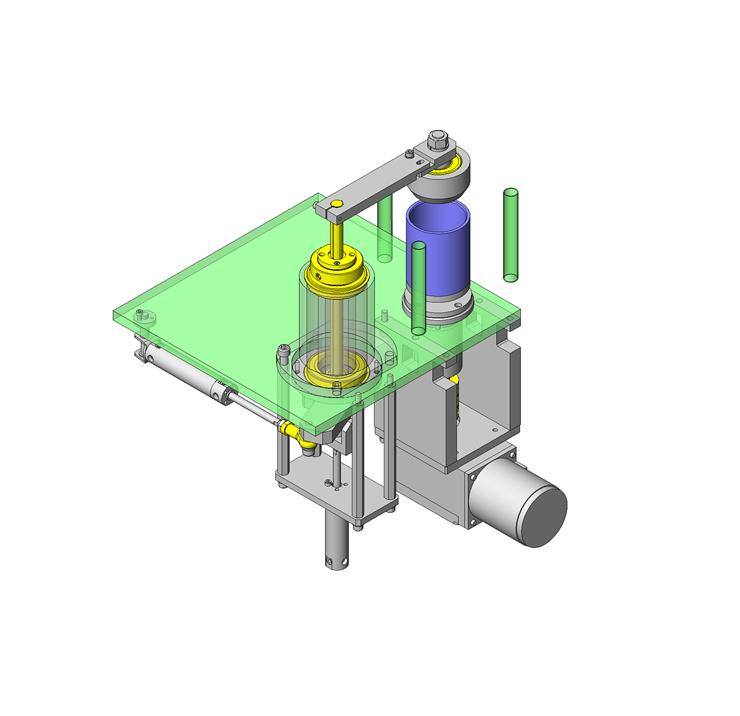

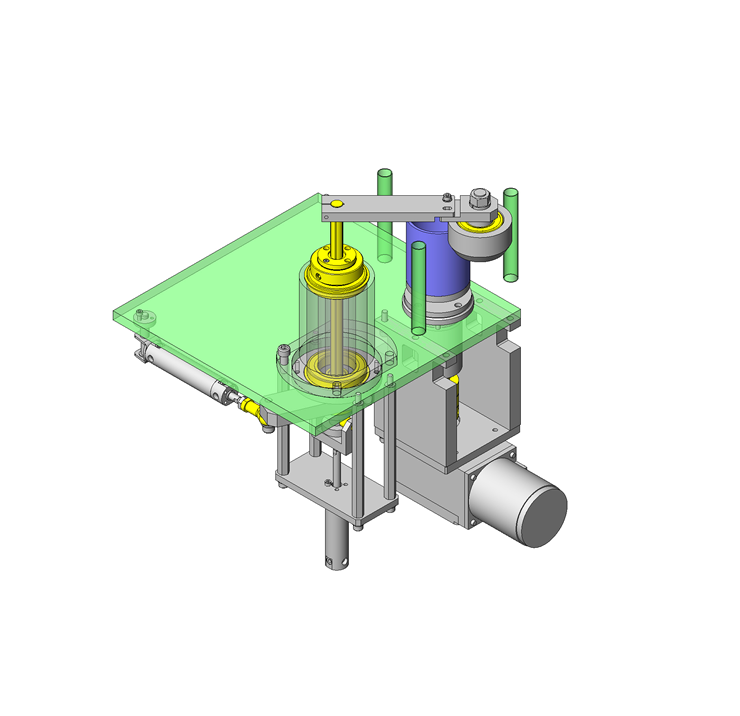

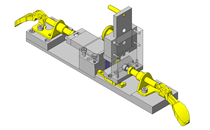

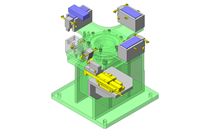

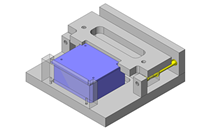

IDEA NOTE Clamping work center

The rotation clamp is designed as a mechanism to allow for positioning adjustments.