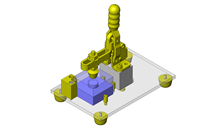

Locating Pins / Head Shape Selectable / Tip Shape Selectable / External Thread / Configurable / g6

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

Dimensional Drawing

● Round

● Diamond

a = 1.0

d = D - 0.2

[ ! ] Relief dimensions are reference values.

[!] When L < Pitch × 2, the incomplete threaded portion (Pitch × 2) is included in M × 1.5.

[!] Fully Threaded Type of L = 0 w/o Pilot is available.

[ ! ] EN 1.4301 Equiv. products may not be polished and have no centering hole.

[ ! ] For EN 1.4037 Equiv., an identification groove is provided on D part, unless the L dimension is short.

| Tip Shape | |

| A Config. |   [ ! ]R ≥ P/2 |

| B Config. |  [ ! ]G ≤ P [ ! ] When G = P, add about C0.2 chamfering |

| C Config. |  [ ! ]R ≤ P/2 Reference: tan30° ≒ 0.577, sin30° = 0.5 |

Materials Table

| Material No. | [M] Material | [S] Surface Treatment | [H] Hardness | P, L, B Configurable | P, L, B, ML Configurable | ||

| Round | Diamond | Round | Diamond | ||||

| (1) | EN 1.2510 Equiv. | — | Treated Hardness: 55 to 60 HRC | LPAJ | LPDAJ | LPAJL | LPDAJL |

| (2) | EN 1.2510 Equiv. | Hard Chrome Plating | Treaded Hardness: 50 to 55 HRC Plating Hardness: 750 HV or more | LPAG | LPDAG | LPAGL | LPDAGL |

| (3) | EN 1.1191 Equiv. | — | Treated Hardness: 45 to 50 HRC | LPA | LPDA | LPANL | LPDAL |

| (4) | EN 1.1191 Equiv. | Black Oxide | Treated Hardness: 45 to 50 HRC | LPAB | LPDAB | LPABL | LPDABL |

| (5) | EN 1.1191 Equiv. | Hard Chrome Plating | Treated Hardness: 45 to 50 HRC Plating Hardness: 750 HV or more | LPAR | LPDAR | LPARL | LPDARL |

| (6) | EN 1.4301 Equiv. | — | — | LPAS | LPDAS | LPASL | LPDASL |

| (7) | EN 1.4301 Equiv. | Hard Chrome Plating | Plating Hardness: 750 HV or more | LPAD | LPDAD | LPADL | LPDADL |

| (8) | EN 1.4037 Equiv. | — | Treated Hardness: 50 to 55 HRC | LPAC | — | LPACL | — |

Specification Table

| Part Number | — | P | — | B | — | R | — | G | — | L | — | ML |

| LPAA5 LPAJB10 LPABLB8 | — — — | P10.00 P15.00 P9.50 | — — — | B12.0 B17.0 B15.0 | — | R6 | — — | G10 G10 | — — — | L5 L10 L7 | — | ML10 |

| Part Number | P 0.01 mm Increments | B 0.1 mm Increments | R 1 mm Increments | G 1 mm Increments | L 1 mm Increments | ML (M × 1.5) | M (Coarse) | Thread Pitch | * Tightening Torque N・cm | (W) | ||||

| Type | Tip Config. | D | D Dimension Tolerance g6 | |||||||||||

| Shape A, Shape C only | Shape B only | |||||||||||||

| A B C | 3 | −0.002 −0.008 | 4.00 to 8.00 | 3.5 to 25.0 (10.0) | Shape A R ≥ P/2 CConfig. R ≤ P/2 | Shape B G ≤ P | 0 to 10 | 4.5 | M3 | 0.5 | 98 | 1.5 | ||

| (Round) | (Diamond) | |||||||||||||

| LPAJ | LPDAJ | 4 | −0.004 −0.012 | 5.00 to 9.00 | 3.5 to 25.0 (10.0) | 6 | M4 | 0.7 | 225 | 1.8 | ||||

| LPAG | LPDAG | 5 | 6.00 to 10.00 | 3.5 to 30.0 (10.0) | 7.5 | M5 | 0.8 | 461 | 2.2 | |||||

| LPA | LPDA | 6 | 7.00 to 12.00 | 3.5 to 40.0 (12.0) | 9 | M6 | 1 | 784 | 3 | |||||

| LPAB | LPDAB | 8 | −0.005 | 9.00 to 15.00 | 3.5 to 40.0 (15.0) | 12 | M8 | 1.25 | 1911 | 3.5 | ||||

| LPAR | LPDAR | 10 | −0.014 | 11.00 to 20.00 | 5.0 to 50.0 (20.0) | 0 to 20 | 15 | M10 | 1.5 | 3783 | 4 | |||

| LPAS | LPDAS | 12 | −0.006 −0.017 | 13.00 to 20.00 | 5.0 to 50.0 (20.0) | 18 | M12 | 1.75 | 6605 | 5 | ||||

| LPAD | LPDAD | 16 | 17.00 to 27.00 | 5.0 to 50.0 (20.0) | 0 to 25 | 24 | M16 | 2 | 16366 | 7 | ||||

| LPAC | 20 | −0.007 −0.020 | 21.00 to 30.00 | 5.0 to 50.0 (20.0) | 30 | M20 | 2.5 | 32928 | 9 | |||||

[ ! ] For full thread, specify L = 0 and NNC alteration.

*The tightening torque (ref. value) for hardened products is strength class 8.8. Not applicable when using locking materials or lock washers.

| Part Number | P 0.01 mm Increments | B 0.1 mm Increments | R 1 mm Increments | G 1 mm Increments | L 1 mm Increments | ML 1 mm Increments | M (Coarse) | Thread Pitch | * Tightening Torque N・cm | (W) | ||||

| Type | Tip Config. | D | D Dimension Tolerance g6 | |||||||||||

| Shape A, Shape C only | Shape B only | |||||||||||||

| A B C | 3 | −0.002 −0.008 | 4.00 to 8.00 | 3.5 to 25.0 (10.0) | Shape A R ≥ P/2 Shape C R ≤ P/2 | Shape B G ≤ P | 0 to 12 | 3 to 9 | M3 | 0.5 | 98 | 1.5 | ||

| (Round) | (Diamond) | |||||||||||||

| LPAJL | LPDAJL | 4 | −0.004 −0.012 | 5.00 to 9.00 | 3.5 to 25.0 (10.0) | 4 to 12 | M4 | 0.7 | 225 | 1.8 | ||||

| LPAGL | LPDAGL | 5 | 6.00 to 10.00 | 3.5 to 30.0 (10.0) | 0 to 15 | 5 to 15 | M5 | 0.8 | 461 | 2.2 | ||||

| LPANL | LPDAL | 6 | 7.00 to 12.00 | 3.5 to 40.0 (12.0) | 6 to 18 | M6 | 1 | 784 | 3 | |||||

| LPABL | LPDABL | 8 | −0.005 | 9.00 to 15.00 | 3.5 to 40.0 (15.0) | 8 to 24 | M8 | 1.25 | 1911 | 3.5 | ||||

| LPARL | LPDARL | 10 | −0.014 | 11.00 to 20.00 | 5.0 to 50.0 (20.0) | 0 to 20 | 10 to 30 | M10 | 1.5 | 3783 | 4 | |||

| LPASL | LPDASL | 12 | −0.006 −0.017 | 13.00 to 20.00 | 5.0 to 50.0 (20.0) | 12 to 30 | M12 | 1.75 | 6605 | 5 | ||||

| LPADL | LPDADL | 16 | 17.00 to 27.00 | 5.0 to 50.0 (20.0) | 0 to 25 | 16 to 40 | M16 | 2 | 16366 | 7 | ||||

| LPACL | 20 | −0.007 −0.020 | 21.00 to 30.00 | 5.0 to 50.0 (20.0) | 20 to 40 | M20 | 2.5 | 32928 | 9 | |||||

[ ! ] For full thread, specify L = 0 and NNC alteration.

*The tightening torque (ref. value) for hardened products is strength class 8.8. Not applicable when using locking materials or lock washers.

Alterations

| Alterations Code | Alteration Details | Application Conditions | Ordering Example |

| SC | Adds Wrench Flats | SC = 1 mm Increments [ ! ]P-3 ≤ SC ≤ P-1,SC ≥ D [ ! ] When B ≤ 11, adds wrench flats on the tip [NG] Not applicable to Diamond Shape | LPAA5-P10.00-B12.0-R6-L5-SC8 |

| LAC | Adds a wrench hole (⌀3.5) | ø3.5 Hole Machining [ ! ] Applicable when B ≥ 10, P ≥ 8 [NG] Not applicable to Diamond Shape | LPAA5-P10.00-B12.0-R6-L5-LAC |

| LTE | Adds a wrench hole (⌀2.5) | ø2.5 Hole Machining [ ! ] Applicable when B ≥ 8, 7 ≤ P ≤ 15 [NG] Not applicable to Diamond Shape | LPAA5-P10.00-B12.0-R6-L5-LTE |

| DRC | Screwdriver Slot | [ ! ] Width 0.8 mm Depth 1 mm | LPAA5-P10.00-B12.0-R6-L5-DRC |

| MC | Changes the thread diameter | [ ! ]D/3 ≤ MC < D [ ! ]MC ≥ 3 [ ! ] The incomplete threaded portion (Pitch × 2) is included. [NG] P, L, B, ML Configurable Types are not applicable | LPAA5-P10.00-B12.0-R6-L5-MC4 |

| NNC | Adds Relief | [ ! ] Applicable when L = 0 | LPAA5-P10.00-B12.0-R6-L0-NNC |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Head Shape | Tip Shape | Surface Treatment | Heat Treatment | Material | [P] Diameter (Head) (mm) | [D] Diameter (Pin) (mm) | [L] Length (Pin) (mm) | [B] Length (Head) (mm) | [G] Length (Tapered tip) (mm) | [R] Radius (Tip) (mm) | [ML] Length (Thread) (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 6 | 3 | 0 ~ 10 | 5 ~ 25 | - | 2 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 9 | 4 | 0 ~ 10 | 5 ~ 25 | - | 2 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 6 ~ 10 | 5 | 0 ~ 10 | 5 ~ 30 | - | 3 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 8 ~ 12 | 6 | 0 ~ 10 | 5 ~ 40 | - | 3 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 10 ~ 15 | 8 | 0 ~ 10 | 5 ~ 40 | - | 4 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 12 ~ 20 | 10 | 0 ~ 10 | 5 ~ 50 | - | 5 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 16 ~ 20 | 12 | 0 ~ 10 | 5 ~ 50 | - | 6 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 18 ~ 24 | 16 | 0 ~ 10 | 5 ~ 50 | - | 8 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 22 ~ 30 | 20 | 0 ~ 10 | 5 ~ 50 | - | 10 ~ 500 | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 6 | 3 | 0 ~ 10 | 5 ~ 25 | 1 ~ 6 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 9 | 4 | 0 ~ 10 | 5 ~ 25 | 1 ~ 9 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 6 ~ 10 | 5 | 0 ~ 10 | 5 ~ 30 | 1 ~ 10 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 8 ~ 12 | 6 | 0 ~ 10 | 5 ~ 40 | 1 ~ 12 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 10 ~ 15 | 8 | 0 ~ 10 | 5 ~ 40 | 1 ~ 15 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 12 ~ 20 | 10 | 0 ~ 10 | 5 ~ 50 | 1 ~ 20 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 16 ~ 20 | 12 | 0 ~ 10 | 5 ~ 50 | 1 ~ 18 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 18 ~ 24 | 16 | 0 ~ 10 | 5 ~ 50 | 1 ~ 24 | - | - | ||

- | 1 | 7 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 22 ~ 30 | 20 | 0 ~ 10 | 5 ~ 50 | 1 ~ 28 | - | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 6 | 3 | 0 ~ 10 | 5 ~ 25 | - | 1 ~ 3 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 5 ~ 9 | 4 | 0 ~ 10 | 5 ~ 25 | - | 1 ~ 4 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 6 ~ 10 | 5 | 0 ~ 10 | 5 ~ 30 | - | 1 ~ 5 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 8 ~ 12 | 6 | 0 ~ 10 | 5 ~ 40 | - | 1 ~ 6 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 10 ~ 15 | 8 | 0 ~ 10 | 5 ~ 40 | - | 1 ~ 7 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 12 ~ 20 | 10 | 0 ~ 10 | 5 ~ 50 | - | 1 ~ 10 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 16 ~ 20 | 12 | 0 ~ 10 | 5 ~ 50 | - | 1 ~ 10 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 18 ~ 24 | 16 | 0 ~ 10 | 5 ~ 50 | - | 1 ~ 12 | - | ||

- | 1 | 7 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Steel] EN 1.1191 Equiv. | 22 ~ 30 | 20 | 0 ~ 10 | 5 ~ 50 | - | 1 ~ 15 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 4 ~ 8 | 3 | 0 ~ 10 | 3.5 ~ 25 | - | 2 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 5 ~ 9 | 4 | 0 ~ 10 | 3.5 ~ 25 | - | 2 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 6 ~ 10 | 5 | 0 ~ 10 | 3.5 ~ 30 | - | 3 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 7 ~ 12 | 6 | 0 ~ 10 | 3.5 ~ 40 | - | 3 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 9 ~ 15 | 8 | 0 ~ 10 | 3.5 ~ 40 | - | 4 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 11 ~ 20 | 10 | 0 ~ 20 | 5 ~ 50 | - | 5 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 13 ~ 20 | 12 | 0 ~ 20 | 5 ~ 50 | - | 6 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 17 ~ 27 | 16 | 0 ~ 25 | 5 ~ 50 | - | 8 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 21 ~ 30 | 20 | 0 ~ 25 | 5 ~ 50 | - | 10 ~ 500 | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 4 ~ 8 | 3 | 0 ~ 10 | 3.5 ~ 25 | 1 ~ 6 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 5 ~ 9 | 4 | 0 ~ 10 | 3.5 ~ 25 | 1 ~ 9 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 6 ~ 10 | 5 | 0 ~ 10 | 3.5 ~ 30 | 1 ~ 10 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 7 ~ 12 | 6 | 0 ~ 10 | 3.5 ~ 40 | 1 ~ 12 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 9 ~ 15 | 8 | 0 ~ 10 | 3.5 ~ 40 | 1 ~ 15 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 11 ~ 20 | 10 | 0 ~ 20 | 5 ~ 50 | 1 ~ 20 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 13 ~ 20 | 12 | 0 ~ 20 | 5 ~ 50 | 1 ~ 20 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 17 ~ 27 | 16 | 0 ~ 25 | 5 ~ 50 | 1 ~ 24 | - | - | ||

- | 1 | 6 Days | 10 | Round | Tapered | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 21 ~ 30 | 20 | 0 ~ 25 | 5 ~ 50 | 1 ~ 30 | - | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 4 ~ 8 | 3 | 0 ~ 10 | 3.5 ~ 25 | - | 1 ~ 3 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 5 ~ 9 | 4 | 0 ~ 10 | 3.5 ~ 25 | - | 1 ~ 4 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 6 ~ 10 | 5 | 0 ~ 10 | 3.5 ~ 30 | - | 1 ~ 5 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 7 ~ 12 | 6 | 0 ~ 10 | 3.5 ~ 40 | - | 1 ~ 6 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 9 ~ 15 | 8 | 0 ~ 10 | 3.5 ~ 40 | - | 1 ~ 7 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 11 ~ 20 | 10 | 0 ~ 20 | 5 ~ 50 | - | 1 ~ 10 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 13 ~ 20 | 12 | 0 ~ 20 | 5 ~ 50 | - | 1 ~ 10 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 17 ~ 27 | 16 | 0 ~ 25 | 5 ~ 50 | - | 1 ~ 12 | - | ||

- | 1 | 6 Days | 10 | Round | Taper R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 21 ~ 30 | 20 | 0 ~ 25 | 5 ~ 50 | - | 1 ~ 15 | - | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 4 ~ 8 | 3 | 0 ~ 12 | 3.5 ~ 25 | - | 2 ~ 500 | 3 ~ 9 | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 5 ~ 9 | 4 | 0 ~ 12 | 3.5 ~ 25 | - | 3 ~ 500 | 4 ~ 12 | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 6 ~ 10 | 5 | 0 ~ 15 | 3.5 ~ 30 | - | 3 ~ 500 | 5 ~ 15 | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 7 ~ 12 | 6 | 0 ~ 15 | 3.5 ~ 40 | - | 4 ~ 500 | 6 ~ 18 | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 9 ~ 15 | 8 | 0 ~ 15 | 3.5 ~ 40 | - | 5 ~ 500 | 8 ~ 24 | ||

- | 1 | 7 Days | - | Round | R | Not Provided | Directly Quenched | [Stainless Steel] EN 1.4037 Equiv | 11 ~ 20 | 10 | 0 ~ 20 | 5 ~ 50 | - | 6 ~ 500 | 10 ~ 30 |

Loading...

Basic information

| Basic Shape | Large Head | Inlet Style | No | Mounting Side Shape | Male thread |

|---|---|---|---|---|---|

| Positioning Side O.D. Tolerance | 0/-0.01 | Mounting Side Outer Dia. Tolerance | g6 |

Configure

Basic Attributes

-

Head Shape

-

Round

Round -

Diamond

Diamond

-

-

Tip Shape

-

Tapered

Tapered -

Taper R

Taper R -

R

R

-

-

Heat Treatment

- No

- Directly Quenched

-

Material

- Steel

- Stainless Steel

- Steel

-

[P] Diameter (Head)(mm)

-

[D] Diameter (Pin)(mm)

-

[L] Length (Pin)(mm)

-

[B] Length (Head)(mm)

-

[G] Length (Tapered tip)(mm)

-

[R] Radius (Tip)(mm)

-

[ML] Length (Thread)(mm)

-

Type

- LPAA

- LPAB

- LPABA

- LPABB

- LPABC

- LPABLA

- LPABLB

- LPABLC

- LPAC

- LPACA

- LPACB

- LPACC

- LPACLA

- LPACLB

- LPACLC

- LPADA

- LPADB

- LPADC

- LPADLA

- LPADLB

- LPADLC

- LPAGA

- LPAGB

- LPAGC

- LPAGLA

- LPAGLB

- LPAGLC

- LPAJA

- LPAJB

- LPAJC

- LPAJLA

- LPAJLB

- LPAJLC

- LPANLA

- LPANLB

- LPANLC

- LPARA

- LPARB

- LPARC

- LPARLA

- LPARLB

- LPARLC

- LPASA

- LPASB

- LPASC

- LPASLA

- LPASLB

- LPASLC

- LPDAA

- LPDAB

- LPDABA

- LPDABB

- LPDABC

- LPDABLA

- LPDABLB

- LPDABLC

- LPDAC

- LPDADA

- LPDADB

- LPDADC

- LPDADLA

- LPDADLB

- LPDADLC

- LPDAGA

- LPDAGB

- LPDAGC

- LPDAGLA

- LPDAGLB

- LPDAGLC

- LPDAJA

- LPDAJB

- LPDAJC

- LPDAJLA

- LPDAJLB

- LPDAJLC

- LPDALA

- LPDALB

- LPDALC

- LPDARA

- LPDARB

- LPDARC

- LPDARLA

- LPDARLB

- LPDARLC

- LPDASA

- LPDASB

- LPDASC

- LPDASLA

- LPDASLB

- LPDASLC

-

Surface Treatment

- Not Provided

- Black Oxide

- Hard Chrome Plating

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 6 Days or Less

- 7 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)