Work Detection Unit

| Product name | Work Detection Units |

| Model number | PCPNA8S-30 |

| Characteristic | Applicable for undetectable places directly by Proximity Sensor. |

* Orange colored cells in the table below indicate the part numbers that were actually used in this app. example.

Selection criteria

Sensor is able to work in adverse conditions.

Back to page top

Risk info.

Bushing slide failure

Back to page top

Available sizes

■Material Detection unit

| Body | Pin | Spring | Pin DIA. | Pin length | Stroke |

| Material | Surface treatment | Material | Surface treatment | Type | Material |

| EN AW-6061 Equiv. | Clear anodize | EN 1.1191 Equiv. | Electroless

nickel plating | Soft,

Hard | EN 1.4301 Equiv. | Ø8 | 30 | 0 (min): OFF, 3 - 8 (max): ON |

| 50 |

Back to page top

Mechanism Info.

■Material Detection sensor structural diagram.

Objects are detected through up / down movement of the shaft, output as ON - OFF signal.

< Operation explanation >

| Stroke |

| 0 (min) | 3 | 8 (max) |

| Sensor |

| OFF | ON | ON |

|  |  |

Back to page top

Performance info.

■Spring load of material detection sensor

| Spring type | Soft | Hard |

| Spring constant (N/mm) | 0.3 | 0.5 |

| Allowable deflection | 12 | 9 |

| Load (N) | min | 1.2 | 2.0 |

| max | 3.6 | 6.0 |

Back to page top

Urethane Bumper

| Product name | Pushers/Urethane/Silicon/Tapped/Flat/Round |

| Model number | URSM12 |

| Characteristic | Bumpers in a wide range of hardness: Shore A30 ~ A90. |

* Orange colored cells in the table below indicate the part numbers that were actually used in this app. example.

Selection criteria

Assists in preventing damage to material being handled.

Back to page top

Available sizes

■Bumpers-Urethane / Silicon, Tapped, Flat/Round

| Pusher | Core metal | O.D. range |

| Material | Hardness | Material | Flat | Round |

Ether-based

Polyurethane | Shore A90 | EN 1.4301 Equiv. | Ø8 - 40 | Ø8 - 40 |

Ester-based

Polyurethane | Shore A70 |

| Shore A50 |

| Shore A30 | Ø8 - 20 | Ø8 - 20 |

| O.D. | Thread - pitch | Overall length | Tip SR

(Round) |

| Ø8 | M3 x 0.5 | 12 | 8 |

| Ø10 | M4 x 0.7 | 15 | 10 |

| Ø12 | M5 x 0.8 | 16 | 12 |

| Ø16 | M6 x 1.0 | 20 | 16 |

| Ø20 | M8 x 1.25 | 25 | 20 |

| Ø25 | M10 x 1.5 | 30 | 25 |

| M10 x 1.25 |

| Ø30 | M12 x 1.75 | 35 | 30 |

| Ø32 | M14 x 1.5 | 37 | 32 |

| Ø36 | M18 x 1.5 | 45 | 36 |

| Ø40 | M20 x 1.5 | 50 | 40 |

| M22 x 1.5 |

Back to page top

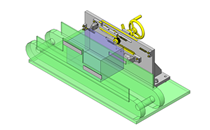

IDEA NOTE Workpiece presence Yes/No detection method

Urethane Bumpers are mounted on the tip of the detection units to avoid scratching the containers.

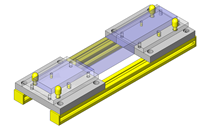

IDEA NOTE Two detection units are used.

When the container is somewhat large as in the supplemental example and position needs to be detected with reliability, 2 detection units placed diagonally increases the reliability. Foreign objects under the tray can be detected as well with this set-up.