- inCAD Library Home

- > No.000172 Space-Saving Long-Stroke Mechanism

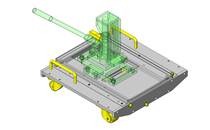

No.000172 Space-Saving Long-Stroke Mechanism

27

27

Speeding up with long stroke

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

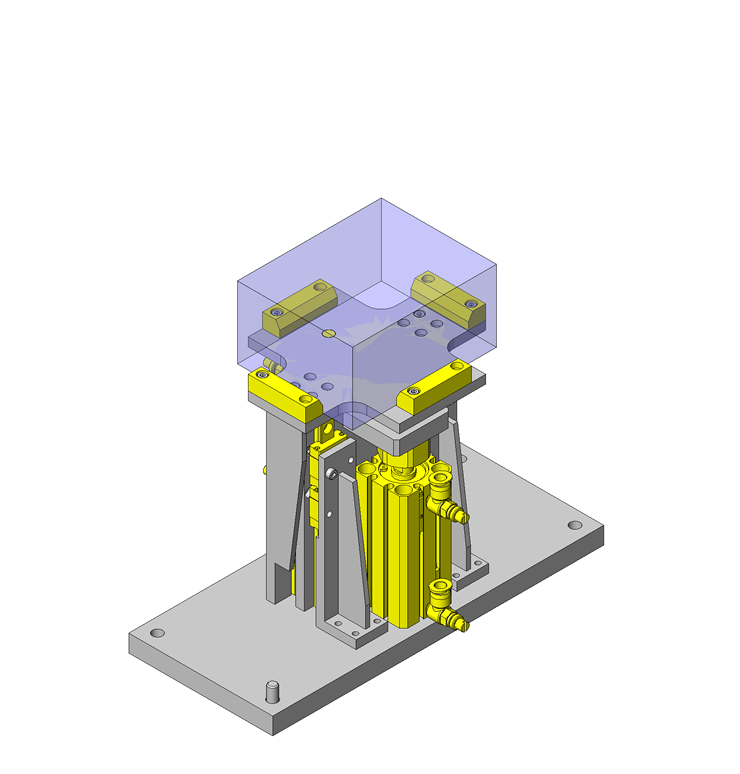

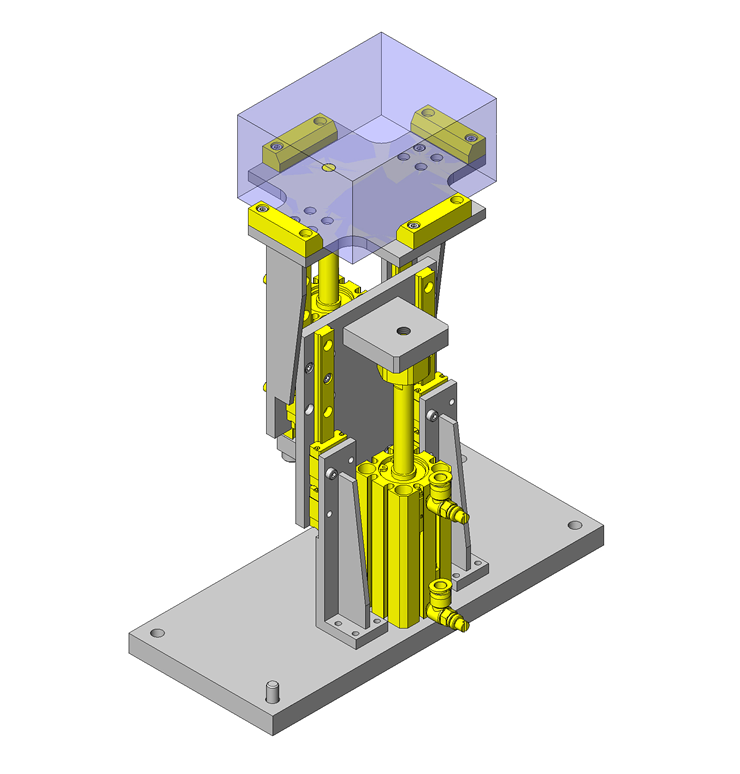

- The lift stroke mechanism retracts to a height below the roller conveyor height (H = 162mm) and advances upward by 100mm up to the processing position when receiving and passing a workpiece on the pallet.

- Operation

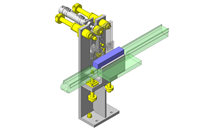

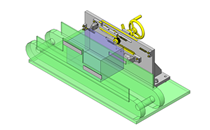

- By using air cylinders and linear guides in combination, the length of the mechanism in the movement direction is shortened while it moves upwards through a long stroke.

Target workpiece

- Shape: box shape workpiece

- Size: W100 x D80 x H50mm

- Weight: 1kg

Design Specifications

Operating Conditions or Design Requirements

- Ascending / descending stroke: 100mm

- Cylinder stroke: 50mm

- Tube inner diameter: Ø20mm

- Cylinder output: 126 x 70%N (Applied pressure 0.4MPa)

- Outer dimensions: W230 x D105 x H157 (H245 when ascended)mm

Required Performance

- Running parallelism: 15 x 2 = 30µm

- Allowable Load: 60N

Selection Criteria for Main Components

- Air Cylinder

- Stroke of 50mm or longer and output of 30N or above

Design Evaluation

Verification of main components

- A cylinder is selected so that the force required for raising the workpiece is obtained.

- Ascending output

- Conditional value: target workpiece mass: M1 = 1kg, ascending structure mass: M2 = 2kg, ascending stroke: L = 100mm, gravitational acceleration g = 9.8m/s², air pressure: a = 0.4MPa, cylinder load factor: η = 70% = 0.7

- Load applied during ascending: W = W1 + W2 = M1 x g + M2 x g = 1 x 9.8 + 2 x 9.8 = 9.8 + 19.6 = 29.4N

- Required cylinder thrust: P = W / η = 29.4 / 0.7 = 42N

⇒A cylinder with a cylinder inner diameter of Ø12mm or higher is selected. - Stroke: L = 100mm, stroke required for each cylinder: L' = L / 2 = 100 / 2 = 50mm

⇒A standard cylinder with a stroke of 50mm and an inner diameter is Ø20mm is selected. - Based on the thrust of a cylinder with a Ø20 inner diameter mm: P', the allowable ascending load: W' is verified.

P'= π / 4 x 20² x 0.4 = 126N

W' = P' x η - W2 = 126 x 0.7 - 19.6 = 68.6N

⇒Allowable ascending load: W' = 68.6N

Other Design Consideration

- When selecting a 100-mm stroke, the cylinder tube inner diameter as well as outer dimensions become larger.

A linear guide that needs to have a length equivalent to the stroke + the guide also becomes longer, making it difficult to be installed in a structure that necessitates escaping. Therefore, this mechanism is effective for space-saving.

Explore Similar Application Examples

Page

-

/

-