- inCAD Library Home

- > No.000301 Width Change Mechanism

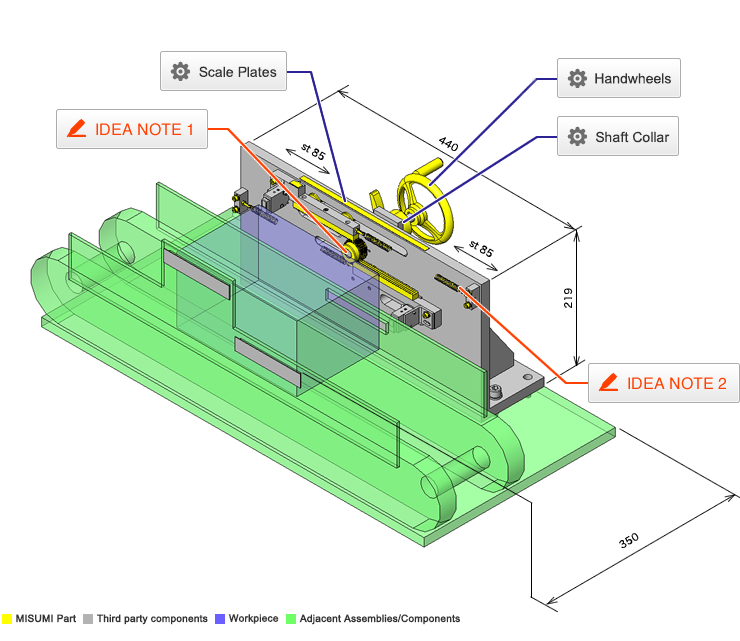

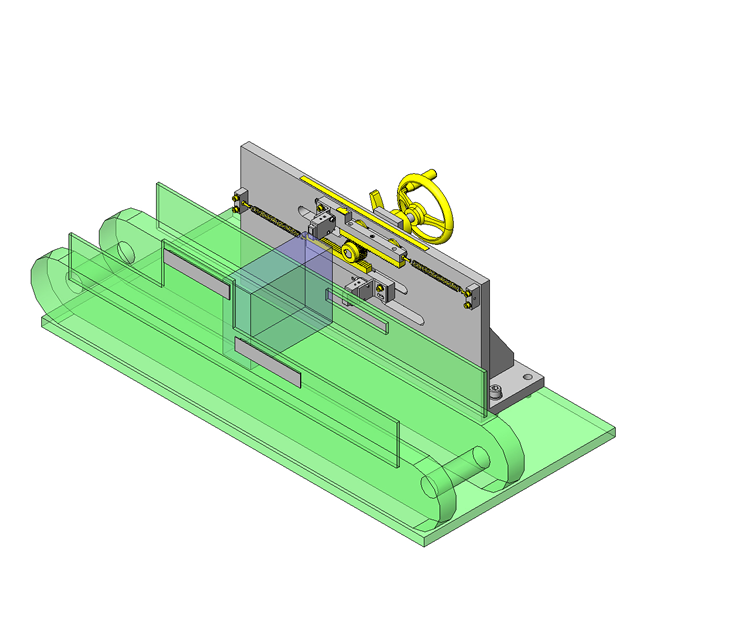

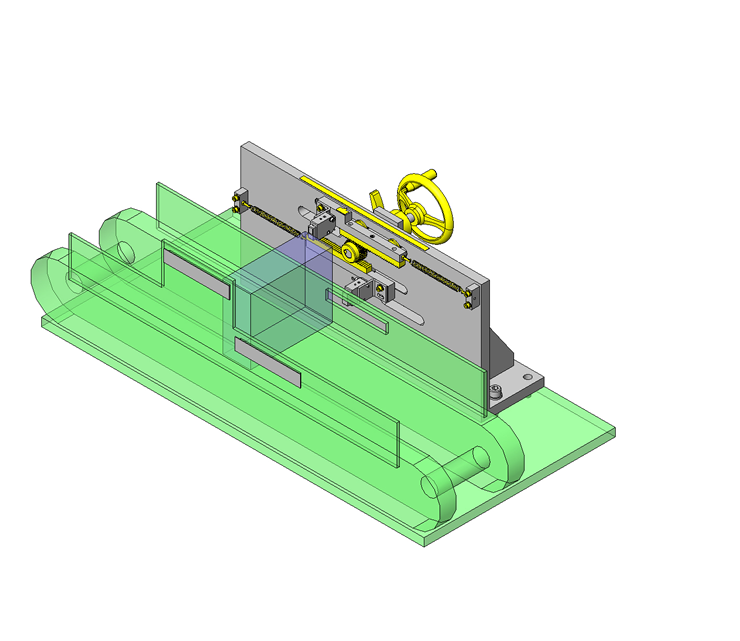

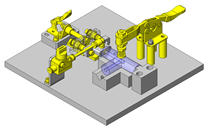

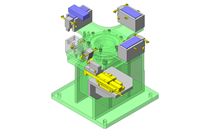

No.000301 Width Change Mechanism

48

48

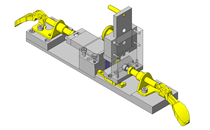

Right and left movement synchronization using center of the workpiece as the reference

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

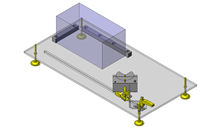

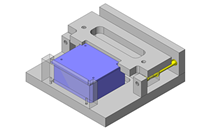

- The sensor position is set up based on the size of the workpiece. (confirmation of the transferred workpiece width)

- Confirm the size of the workpiece based on values on the scale plate. (Example: Applicable to workpiece A when the scale is 10mm)

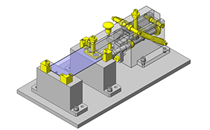

- Width of workpiece is changed equal from both sides (left and right) using center of the workpiece as the reference.

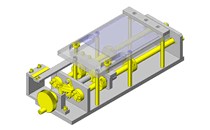

- The backlash is reduced using tensile springs.

Points for use

- A handle is used for adjustment, and rotation is stopped using a shaft collar.

- A retro-reflective type is used for the sensor.

Target workpiece

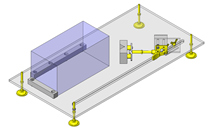

- Plastic BOX

- Outer shape of large workpiece: W220 x D150 x H120mm

- Outer shape of small workpiece: W50 x D150 x H120mm

Design Specifications

Operating Conditions or Design Requirements

- External Dimensions: W440 x D350 x H219mm

- One side preparation stroke: 85mm

Selection Criteria for Main Components

- Shaft collar

- Selected as "fixed" after an adjustment.

- Handle

- A handle which allows easy adjustment is selected.

- Tensile Springs

- Selected to reduce backlash.

- Rack Gear

- Two sections are selected to achieve synchronization.

Design Evaluation

Verification of main components

- The maximum distortion of a spring is verified based on the load conditions.

- Spring Load

- (i) When minimum width is set.

- Conditional Values: Initial tension 3.43N, Deflection when tensile is expected x = 0mm.

- Formula: Based on reaction force F = kx + Initial tension, F = 3.43N

(ii) When maximum width is set. - Formula: Reaction force F = kx + Initial tension

- Initial Tension: 3.43N

- Deflection when tension is expected: x = 85mm

- Maximum deflection (mm) x = Configurable S Dimension (= 75mm)/Standard S Dimension (= 50mm) x Standard maximum deflection (= 57mm) = 75/50 x 57 = 85.5 (mm) > 85mm

Established based on Deflection when tension is expected ≦ Maximum deflection. - Spring Constant k(N/mm) = 50 (Reference S Dimension) /Configurable S Dimension (= 75mm) x Standard Spring Constant (= 0.34N/mm) = 50/75 x 0.34 = 0.23(N/mm)

- Reaction force F = k(= 0.23 N/mm) x x(= 85.5mm) + Initial Tension (= 3.43N) = 0.23 x 85.5 + 3.43 = 23.1N

Other Design Consideration

- The sliding performance of the rack is improved during synchronization by placing oil-free bushings with high O.D. dimension accuracy in the slotted hole area.

Explore Similar Application Examples

Page

-

/

-