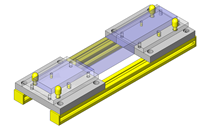

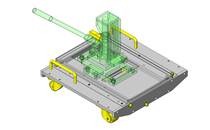

Fixture Slides

| Product name | Tool Sliders/Guide Rail Type |

| Part number | JGR250 |

| Features | High load capacity is achieved by use of guide rails. Suitable for high load applications, such as press-fitting, press and machining. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Select the slide unit with guide for mounting/dismounting workpieces.

Back to page top

Available sizes

■Fixture Slides - Guide Rail Type

| Main Body | Material | Surface Treatment |

| Table | EN 1.1191 Equiv. Thermal Refined Material | Electroless

Nickel Plating |

| Plate |

| Guide Rail |

| Handle Bracket | EN 1.1191 Equiv. |

| Handle | Alum. Alloy | Clear Anodize |

■Sizes and Dimensions

| Type | Stroke

(mm) | Table Size

(mm) | Base Length

(mm) |

|

| 150 | 50 ・ 100 ・ 150 | 150 x 150 | 325 |

| 250 | 150 ・ 200 ・ 250 | 150 x 150 | 425 |

Back to page top

Performance info.

■Speeds・Loads (Load info.) of Sliders for Fixture

| Type | Required Thrust

(N) | Plunger Retaining Force

(N) | Withstand Load

(kN) |

|

| 150 | 10 | 30 | 37.2 |

| 250 | 10 | 30 | 37.2 |

Back to page top

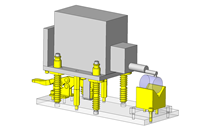

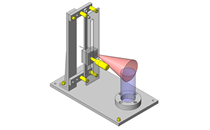

Air Cylinders

| Product name | Air Cylinders/Pen/Double Acting |

| Part number | MSPCN20-50 |

| Features | Double Acting Type Cylinders - Compact and Pen-style - for increased space saving |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

General as drive source.

Back to page top

Available sizes

■Air Cylinders - Pen, Double Acting

Cyl.

Bore | Cylinder Stroke | Cylinder O.D. | Overall Length

(Listed below + St) |

| St | 15 | 25 | 30 | 45 | 50 | 60 | 100 |

| Ø6 | ○ | - | ○ | ○ | - | ○ | - | 12 x 12 | 77 |

| Ø10 | ○ | - | ○ | ○ | - | ○ | - | 12 x 12 | 74 |

| Ø16 | ○ | - | ○ | ○ | - | ○ | - | 18 x 18 | 75 |

| Ø20 | ○ | ○ | - | - | ○ | - | ○ | 28 x 28 | 131 |

| Ø25 | ○ | ○ | - | - | ○ | - | ○ | 33.5 x 33.5 | 142 |

| Ø32 | ○ | ○ | - | - | ○ | - | ○ | 37.5 x 37.5 | 155 |

* Sensor is sold separately

Back to page top

Selection steps

■Cylinder Selection Steps

1. Define various load conditions

↓

2. Calculate cylinder output. (in case of double acting cylinder)

↓

3. Determine cylinder bore

↓

4. Determine theoretical reference speed

↓

5. Verify cylinder's cushion mechanism

↓

6. Verify applicable lateral load on the cylinder

Back to page top

Performance info.

■Compact Cylinder Operating Pressure Range

Min. Operating Pressure (MPa): 0.06

Max. Operating Pressure (MPa): 0.7

Pressure Resistance (MPa): 1.0

■Theoretical Thrust

(N)

Cyl.

bore | Operating

Direction | Operating Pressure (MPa) |

| 0.4 | 0.5 |

| Ø6 | Push | 11.3 | 14.1 |

| Pull | 8.5 | 10.6 |

| Ø10 | Push | 31.4 | 39.3 |

| Pull | 26.4 | 33 |

| Ø16 | Push | 80 | 101 |

| Pull | 73 | 91 |

| Ø20 | Push | 126 | 157 |

| Pull | 94 | 118 |

| Ø25 | Push | 196 | 245 |

| Pull | 165 | 206 |

| Ø32 | Push | 322 | 402 |

| Pull | 346 | 415 |

■Allowable Lateral Load

Back to page top

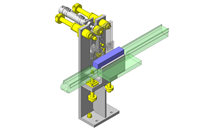

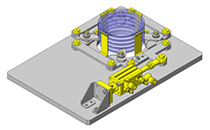

Dustproof General

| Product name | Dustproof General-Purpose Sponges |

| Part number | EPA-100-100-5 |

| Features | High performance sealing material that can fill all types of gaps to keep out heat, moisture and sound. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Provides an air tight seal

Back to page top

Risk info.

Cutting may be required to suit workpiece size.

Back to page top

Available sizes

■Dustproof General-Purpose Sponges

| Material |

| Sponge | Seal |

EPDM Foam

(EPT Sealer®) | Adhesive with Unwoven

Cloth Base Material |

|

EPDM Foam

(Opsealer®) | Adhesive with Net

Base Material |

|

■Sizes and Dimensions

| 10 mm Increment | Thickness (Selectable) |

| Long Length Direction | Short Length Direction |

| 20 ~ 500 | 20 ~ 400 | 3 |

| 5 |

| 8 |

| 10 |

| 15 |

| 20 |

| 25 |

| 30 |

Back to page top

Accuracy Info

■Accuracy of Dustproof General

| Thickness | Tolerance |

| 3 ~ 10 | ±1.0 |

| 15 ~ 25 | ±2.0 |

| 30 | ±2.5 |

| External Dimensions | Tolerance |

| 20 | ±2.0 |

| 30 ~ 50 | ±2.5 |

| 60 ~ 140 | ±3.5 |

| 150 ~ 290 | ±6.5 |

| 300 ~ 500 | ±9.0 |

Back to page top

Performance info.

■Characteristic Value of Dustproof General

* The values are not guaranteed but measured ones.

| Measurement Item | EPA

(Unwoven Cloth Base Material) | EPAOP

(Net Base Material) |

| Color | Black | Black |

| Specific Gravity | 0.11 | 0.08 |

| Tensile Strength | 0.08 | 0.1 |

| Elongation (%) | 450 | 205 |

| Compression Hardness (25%) (kg/cm²) | 0.02 | 0.04 |

| Compression Hardness (50%) (kg/cm²) | 0.05 | 0.05 |

| Compression Ratio (%) | 50 | x | △ |

| 60 | △ | ○ |

| 70 | ○ | ○ |

| 80 | ○ | ○ |

○: No leakage of water after 30min.

△: Leakage of water is seen after 30min.

X: Leakage of water is seen within 10min.

Back to page top

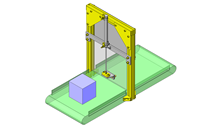

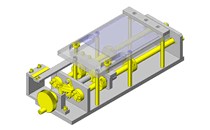

IDEA NOTE Checks air leakage by creating an air tight condition with a cylinder.

Compresses the sheet mounted on the pusher by using cylinder thrust.