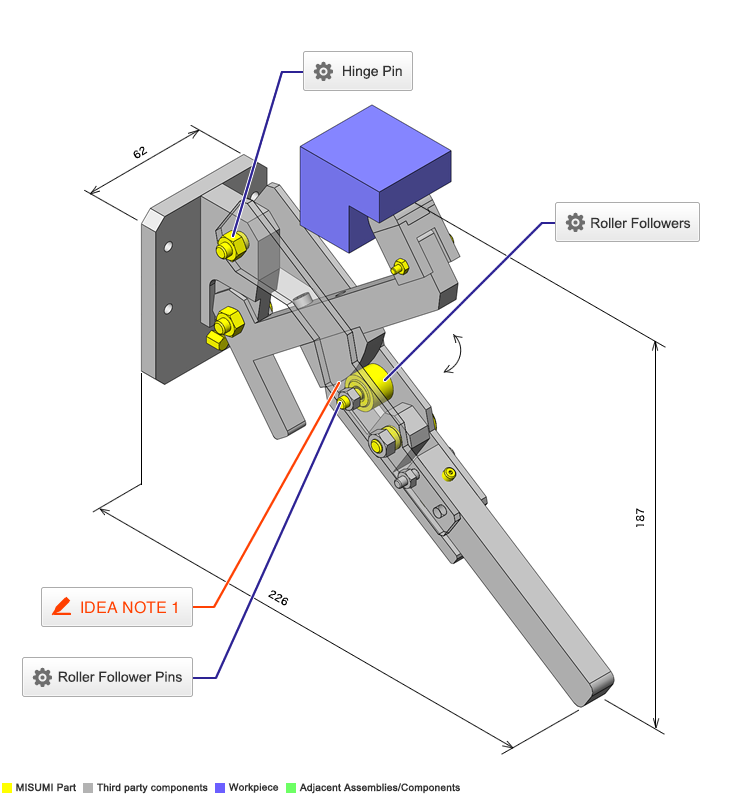

Roller Followers

| Product name | Roller Followers/Solid |

| Part number | NARTUC5 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Selecting the needle structure type that is hard to separate, for the concern of possible excessive load applied at clamp timing.

Back to page top

Available sizes

■Roller Followers - Solid

| Grease | No Seal | With Seal | Material |

| Crowned | Flat Type | Crowned | Flat Type |

| General | ○ | ○ | ○ | ○ | EN 1.3505 Equiv. |

| ○ | - | ○ | ○ | EN 1.4125 Equiv. |

| Low Rebound | - | - | ○ | - |

■Sizes and Dimensions

No Seal

O.D.

(mm) | I.D.

(mm) | Thickness(mm) |

|

| 16 | 5 | 11 |

| 19 | 6 |

| 24 | 8 | 14 |

| 30 | 10 |

| 32 | 12 |

With Seal

O.D.

(mm) | I.D.

(mm) | Thickness(mm) |

|

| 16 | 5 | 11 |

| 19 | 6 |

| 24 | 8 | 14 |

| 30 | 10 |

| 32 | 12 |

| 35 | 15 | 18.0 |

| 40 | 17 | 20.0 |

| 47 | 20 | 24.0 |

Back to page top

Accuracy Info

■Accuracy Information of Roller Followers

- Shaft Dia. Tolerance:

- 0

-0.008(mm)

- Roller Dia. Tolerance:

- 0

-0.005(mm)

Back to page top

Performance info.

■Speeds・Loads (Load info.) of roller followers

No Seal

I.D.

- O.D. | Basic Dynamic Load Rating

C (kN) | Basic Static Load Rating

Cor (kN) | Track Load

Capacity (kN) | Max. Rotational Speed (rpm) |

|

| Crowned | Flat

Type | Crowned | Flat

Type | Crowned | Flat

Type |

| Ø5-Ø16 | 2.84 | 6.46 | 2.65 | 7.81 | 1.08 | 25000 | 10500 |

| Ø6-Ø19 | 3.33 | 7.58 | 3.35 | 10.2 | 1.37 | 20000 | 8700 |

| Ø8-Ø24 | 5.68 | 11.7 | 5.89 | 15.6 | 1.86 | 17000 | 7000 |

| Ø10-Ø30 | 7.94 | 15.8 | 7.59 | 18.5 | 2.45 | 15000 | 5700 |

| Ø12-Ø32 | 8.53 | 17.0 | 8.44 | 21.0 | 2.74 | 13000 | 5200 |

With Seal

I.D.

- O.D. | Basic Dynamic Load Rating

C (kN) | Basic Static Load Rating

Cor (kN) | Track Load

Capacity (kN) | Max. Rotational Speed (rpm) |

|

| Crowned | Flat

Type | Crowned

Type | Flat

Type | Crowned

Type | Flat

Type |

| Ø5-Ø16 | 2.84 | 6.46 | 2.65 | 7.81 | 1.08 | 10000 | 4200 |

| Ø6-Ø19 | 3.33 | 7.58 | 3.35 | 10.2 | 1.37 | 8000 | 3480 |

| Ø8-Ø24 | 5.68 | 11.7 | 5.89 | 15.6 | 1.86 | 6800 | 2800 |

| Ø10-Ø30 | 7.94 | 15.8 | 7.59 | 18.5 | 2.45 | 6000 | 2280 |

| Ø12-Ø32 | 8.53 | 17.0 | 8.44 | 21.0 | 2.74 | 5200 | 2080 |

| Ø15-Ø35 | 13.7 | 25.3 | 16.4 | 36.9 | 3.14 | 4000 | 1720 |

| Ø17-Ø40 | 17.4 | 32.0 | 19.3 | 46.6 | 3.72 | 3800 | 1560 |

| Ø20-Ø47 | 22.9 | 41.7 | 30.6 | 67.7 | 7.15 | 3200 | 1360 |

Back to page top

Roller Follower Pins Threaded

| Product name | Roller Follower Pins/Threaded |

| Part number | FSRFN5-25-F6 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

It is easy to install because one side has a head.

Back to page top

Available sizes

■Roller Follower Pins (Threaded)

| Material | Surface Treatment |

| EN 1.1191 Equiv. | Black Oxide |

| EN 1.4301 Equiv. | - |

■Sizes and Dimensions

Pin Dia.

(mm) | Pin Length

(mm) | Thread Length

(mm) |

|

| 5 | 20, 25, 30 | 14 |

| 6 | 30, 32, 34, 36 |

| 8 | 30, 32, 34, 36, 38 | 16 |

| 10 | 36, 38, 42 | 19 |

| 12 | 38, 42, 46 | 22 |

| 15 | 38, 42, 46, 50 | 25 |

| 17 | 28 |

| 20 | 38, 42, 46, 50, 54 | 31 |

Back to page top

Hinge Pin

| Product name | Precision Pivot Pins/Flanged/Hex Socket Head/Threaded with Lock Nut |

| Part number | SCLBR4-20 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

It enables one to obtain the components that normally require large amount of machining such as flange by ready-made products.

Back to page top

Available sizes

■Hinge Pins - Flanged, Hex Socket Head, Threaded with Lock Nut

| Material | Hardness | Surface Treatment | Included nut material |

| Standard nut | U nut |

| EN 1.1191 Equiv. | - | Black Oxide | JIS-SWRCH | EN 1.0038 Equiv. |

| 40 ~ 45HRC |

| - | Electroless Nickel Plating | EN 1.4301 Equiv. | EN 1.4301 Equiv. |

| 40 ~ 45HRC |

| Plating hardness 750HV - | Hard Chrome Plating

Plating Thickness 3 μm or more | JIS-SWRM | EN 1.0038 Equiv. |

| EN 1.4301 Equiv. | - | - | EN 1.4301 Equiv. | EN 1.4301 Equiv. |

| EN 1.4125 Equiv. | 45 ~ 50HRC |

45 ~ 50HRC

Plating hardness 750HV - | Hard Chrome Plating

Plating Thickness 3 μm or more |

■Sizes and Dimensions

| Pin Dia. | Pin section length

(Configurable in 0.1 mm increment) | Head O.D. | Head Height | Thread Length | Thread Dia. X Pitch |

| Ø4 | 10.0- 50.0 | Ø7 | 5 | 6 | M3 x 0.5 |

| Ø5 | 10.0- 60.0 | Ø9 | M4 x 0.7 |

| Ø6 | 10.0-100.0 | Ø10 | 9 | M5 x 0.8 |

| Ø8 | 10.0-100.0 | Ø13 | M6 x 1.0 |

| Ø10 | Ø16 | 12 | M8 x 1.25 |

| Ø12 | 10.0-200.0 | Ø18 | 16 | M10 x 1.5 |

| Ø13 | 20.0-200.0 | Ø24 | 18 | M12 x 1.75 |

| Ø14 |

| Ø15 |

| Ø16 | 20.0-200.0 |

| Ø17 |

| Ø18 | 24 |

| Ø20 | Ø27 | M16 x 2.0 |

| Ø22 | 20.0-200.0 |

| Ø25 | Ø30 |

Back to page top

Accuracy Info

■Pivot pin, Flanged with Hex socket, Tapped: Pin Dia. tolerance (g6)

| Pin Dia. | Tolerance |

| Ø4-Ø6 | -0.004

-0.012 |

|

| Ø8 ・ Ø10 | -0.005

-0.014 |

|

| Ø12-Ø18 | -0.006

-0.017 |

|

| Ø20 ・ Ø22 ・ Ø25 | -0.007

-0.020 |

|

Back to page top

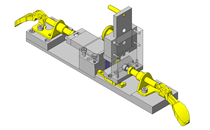

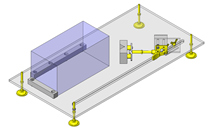

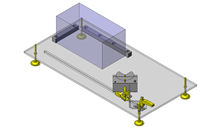

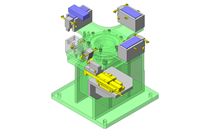

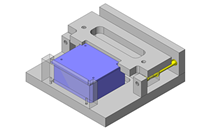

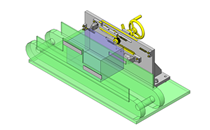

IDEA NOTE Cam follower wedge

Cam follower and wedge are used to allow for easy rolling motion and to minimise dust generation.